Automotive electric hydraulic power-assisted steering pump assembly

A hydraulic power steering and vehicle electric technology, which is applied in the direction of fluid steering mechanism, rotary piston type/swing piston type pump components, rotary piston type/swing piston type pump combination, etc. Large space, separate installation of oil tank and other problems, to achieve the effect of saving external space, simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

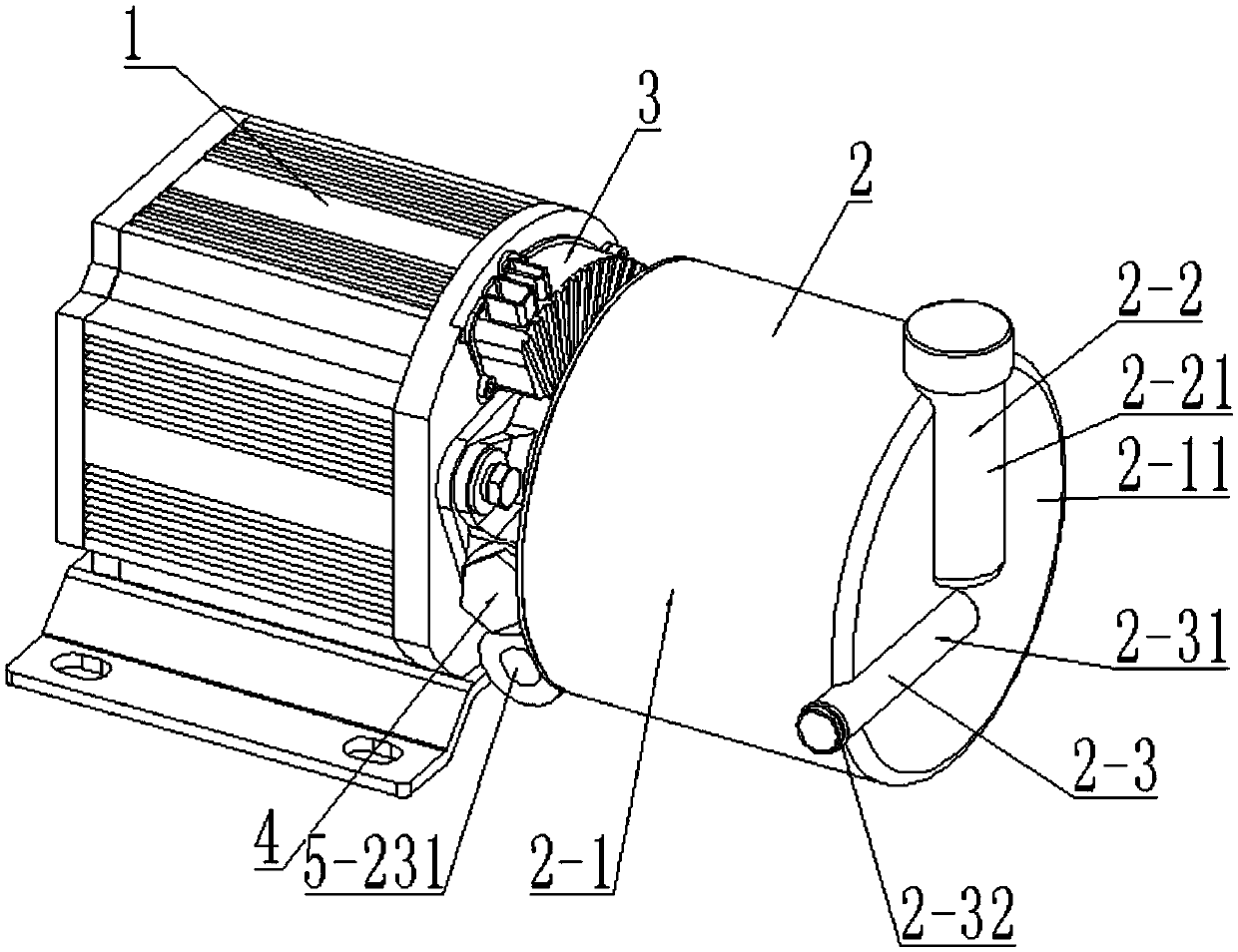

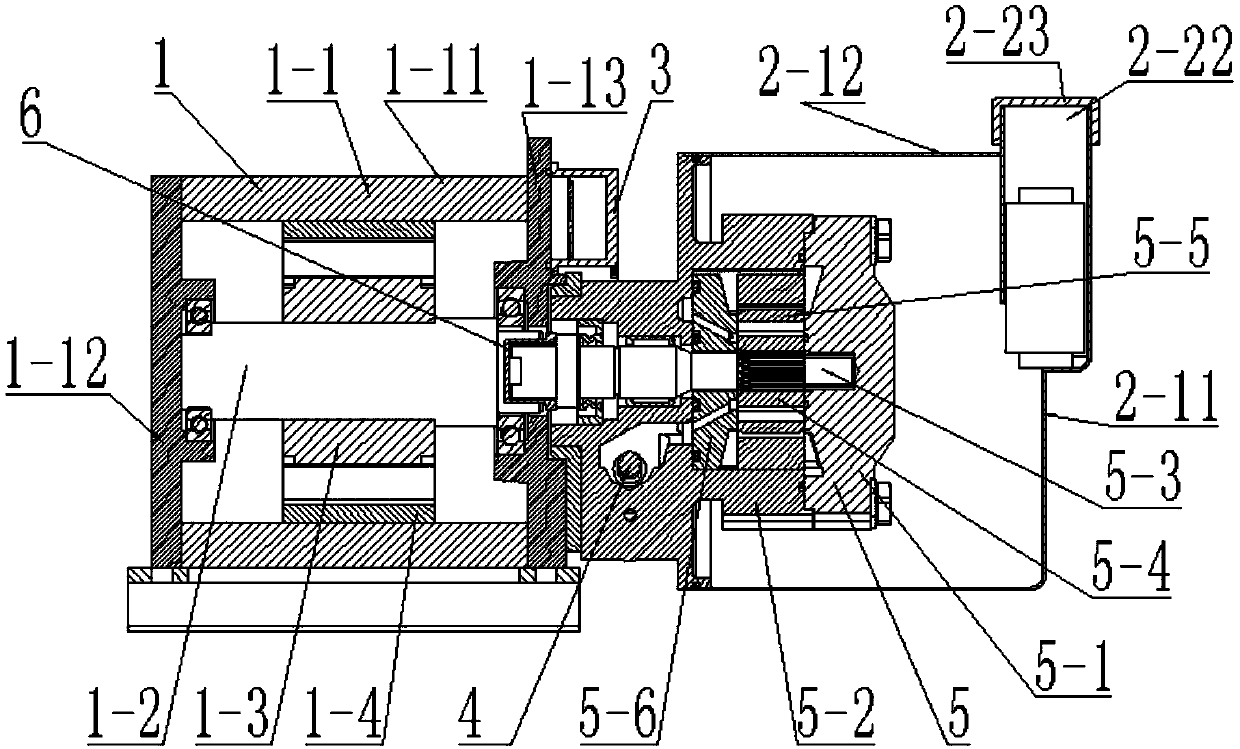

[0047] Such as Figure 1-Figure 8 As shown, an electric hydraulic power steering pump assembly for a vehicle includes a motor 1, an oil tank 2, and a hydraulic pump 5. A controller assembly 3 is provided between the motor 1 and the oil tank 2, and the motor 1 includes a body 1-1 and a motor shaft 1-2. The body 1-1 includes a motor rear cover 1-12, a motor front cover 1-13, and a motor rear cover 1-12 and a motor front cover The housing 1-11 between 1-13, the motor shaft 1-2 and the housing 1-11 are coaxially arranged;

[0048] The hydraulic pump 5 is a double-acting vane pump. The hydraulic pump 5 includes a pump body 5-2, a pump cover 5-1, and a pump shaft 5-3. The pump body 5-2 includes an integral structure from front to back. The pump body main body 5-21, the pump body connection end cover 5-22 and the valve body mounting part 5-23, the front end of the pump body main body 5-21 is connected with the pump cover 5-1, the pump body main body 5- 21 and the pump cover 5-1 are ar...

Embodiment 2

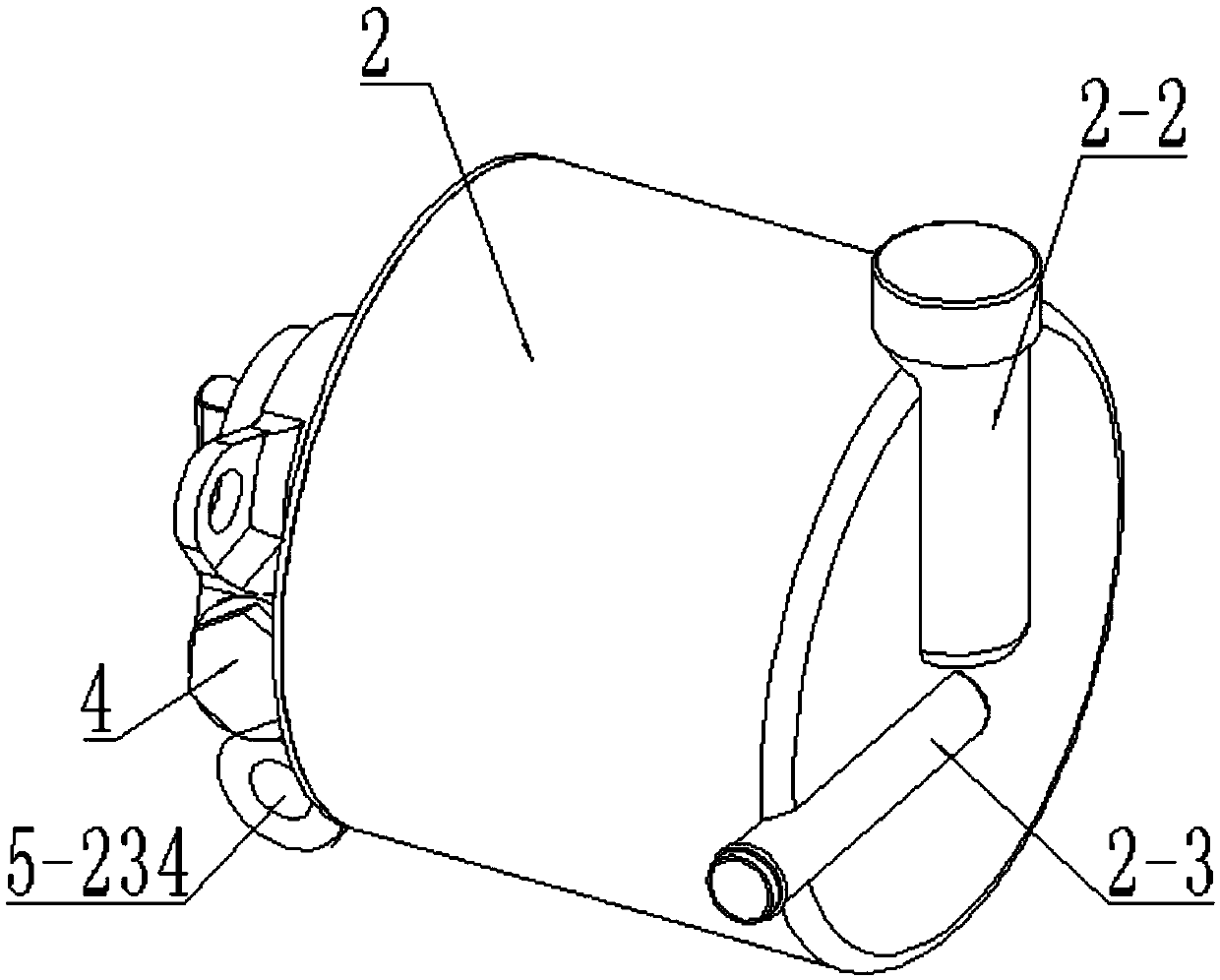

[0064] Such as Picture 10 As shown, the difference from Embodiment 1 is that: the first arc-shaped protrusion 2-21 and the front can cover 2-11 form an integral structure, and the second arc-shaped protrusion 2-31 is The cylindrical tank body 2-12 is an integral structure, and the second arc-shaped protrusion 2-31 is provided under the cylindrical tank body 2-12; the center of the oil injection connection port 2-22 The axis is perpendicular to the central axis of the cylindrical tank 2-12, and the central axis of the oil return connection port 2-32 is parallel to the central axis of the cylindrical tank 2-12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com