Novel halogen strip lamp

A halogen and lamp technology, which is applied in the direction of incandescent lamps, incandescent lamp parts, and the sealing between tube and shell parts, can solve the problem that the structure, performance and use effect cannot meet market requirements well, low luminous efficiency, gas filling Problems such as low pressure, to achieve the effects of simplifying production equipment, low power consumption, and suppressing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

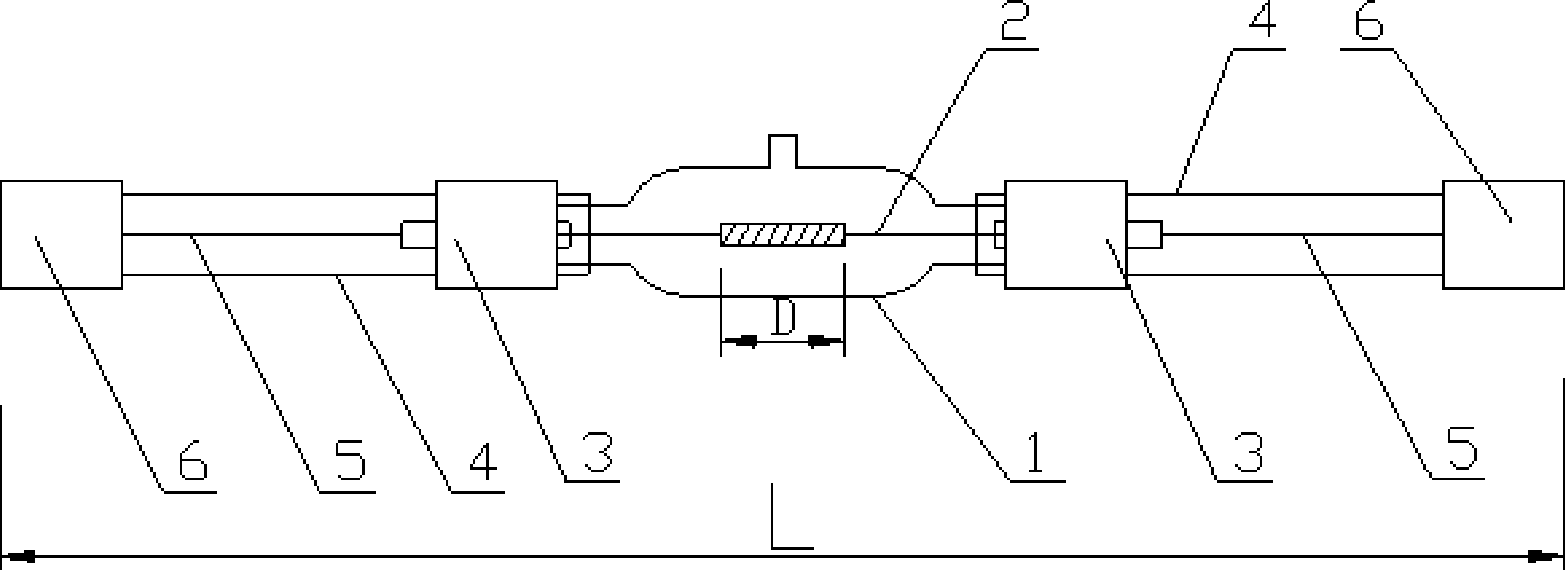

[0011] Embodiments of the present invention: the structure of the present invention is as figure 1 As shown, the bulb 1 is a quartz glass tube, and the two ends of the bulb 1 are respectively assembled and connected with porcelain heads 3, and the wire feet at both ends of the filament 2 are respectively welded on the molybdenum sheet, and the filament in the light-emitting area of the present invention adopts a filament with a double helix structure Or the filament of the triple helix structure, the filament of the double helix structure is a filament made of a straight tungsten wire wound twice; the filament of a triple helix structure is a filament made of a straight tungsten wire wound three times. The use of double-helix filament or triple-helix filament can shorten the length of the filament 2 and the corresponding bulb 1. When sealing the bulb 1, fill the shortened bulb 1 with halogen gas so that the air pressure in the bulb 1 is 2~ 3 standard atmospheric pressures; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com