Rubber composition for conveyor belt and conveyor belt

A technology of rubber composition and conveyor belt, which is applied in the field of rubber composition and conveyor belt, and can solve the problems of equipment cost and energy consumption increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0036] In the first rubber composition used in the conveyor belt of the present invention, the content of the silane coupling agent is 0.5 to 3 parts by weight, and preferably 1 to 2 parts by weight, per 100 parts by weight of the rubber component.

[0037] diethylene glycol

[0038] In the first rubber composition used in the conveyor belt of the present invention, the content of diethylene glycol per 100 parts by weight of the rubber component is 0.5 to 4.5 parts by weight, preferably 0.5 to 2 parts by weight, and more preferably 0.6 to 2 parts by weight. 1.8 parts by weight.

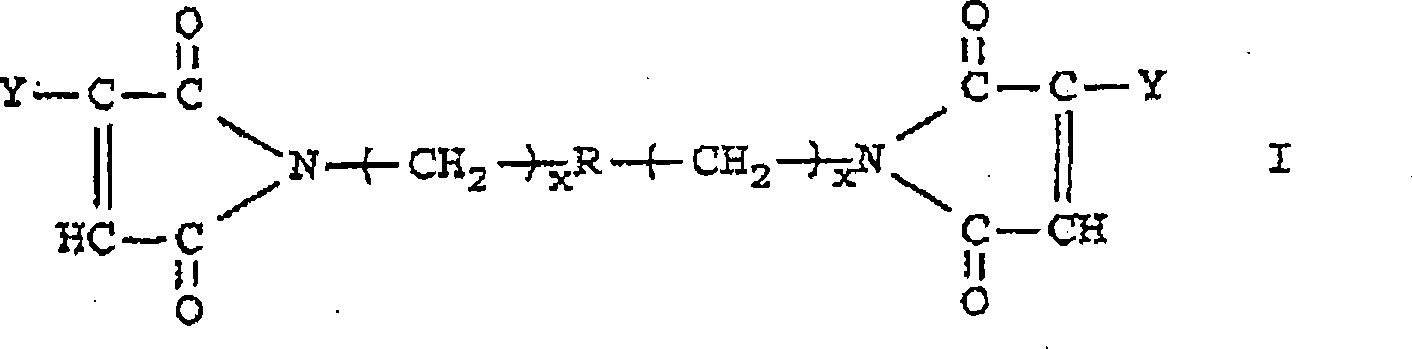

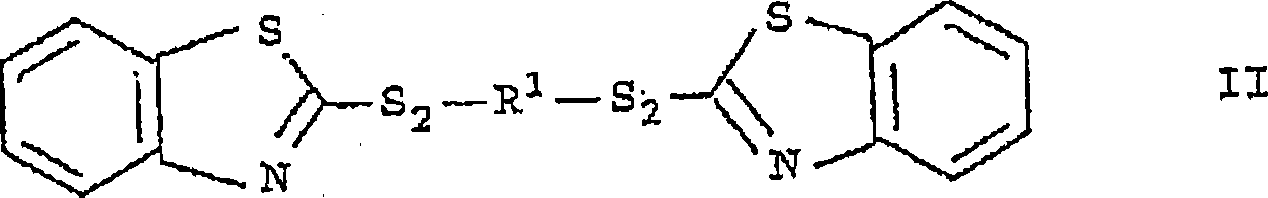

[0039] In addition to the above ingredients, in a preferred embodiment, the first rubber composition for the conveyor belt of the present invention also includes 1,3-bis(citraconimidomethyl)benzene (1,3-bis(citraconimidomethyl) )benzene) and / or hexamethylene-1,6-bis(thiosulfate) disodium salt dihydrate.

[0040]

[0041] Inclusion of these compounds makes the energy loss index (ΔH) described later ...

Embodiment

[0081] The rubber composition used in the conveyor belt of the present invention is described in more detail in the following examples, which are illustrative and not intended to limit the invention.

[0082] Physical properties after vulcanization

[0083] (2) Wear resistance

[0084] (3) Loss factor tan δ

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com