Resonance enhanced drilling method and apparatus

A drilling equipment and equipment technology, applied in drilling equipment, drilling with vibration, automatic control system for drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

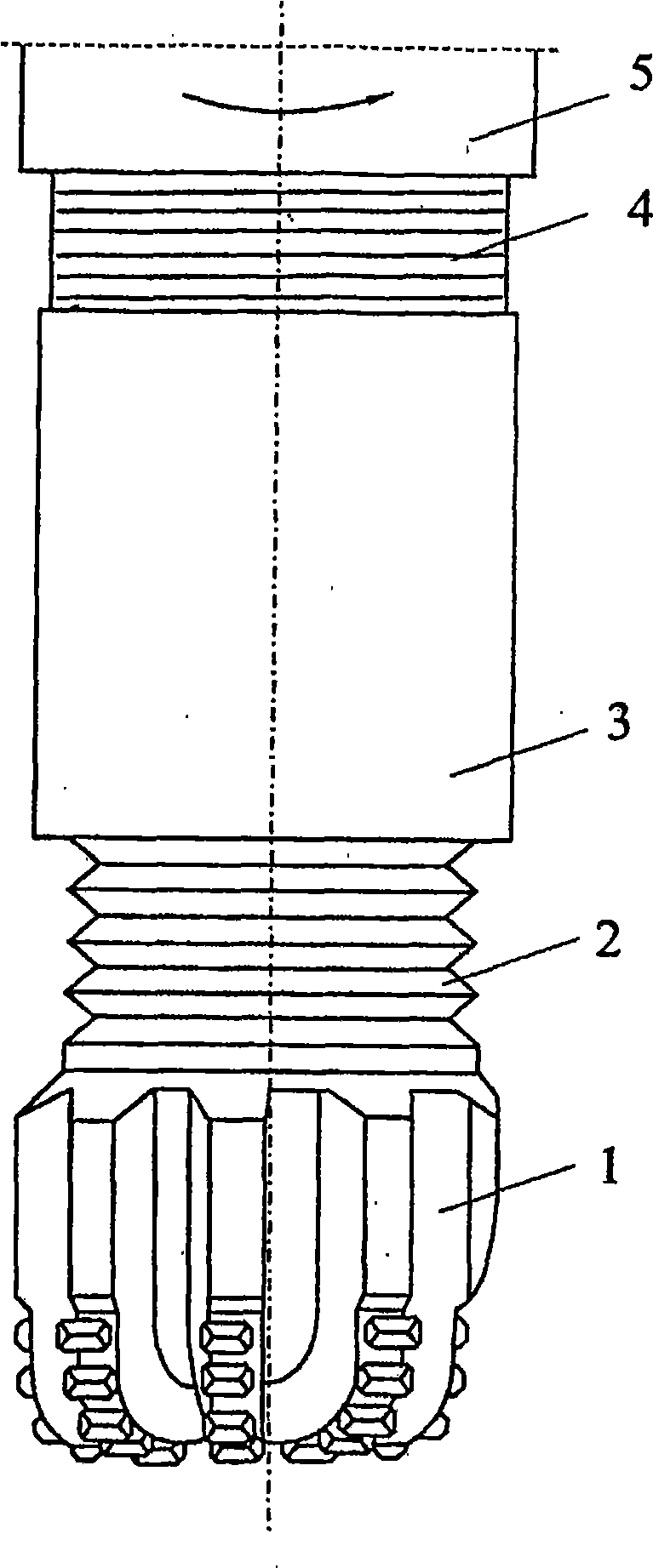

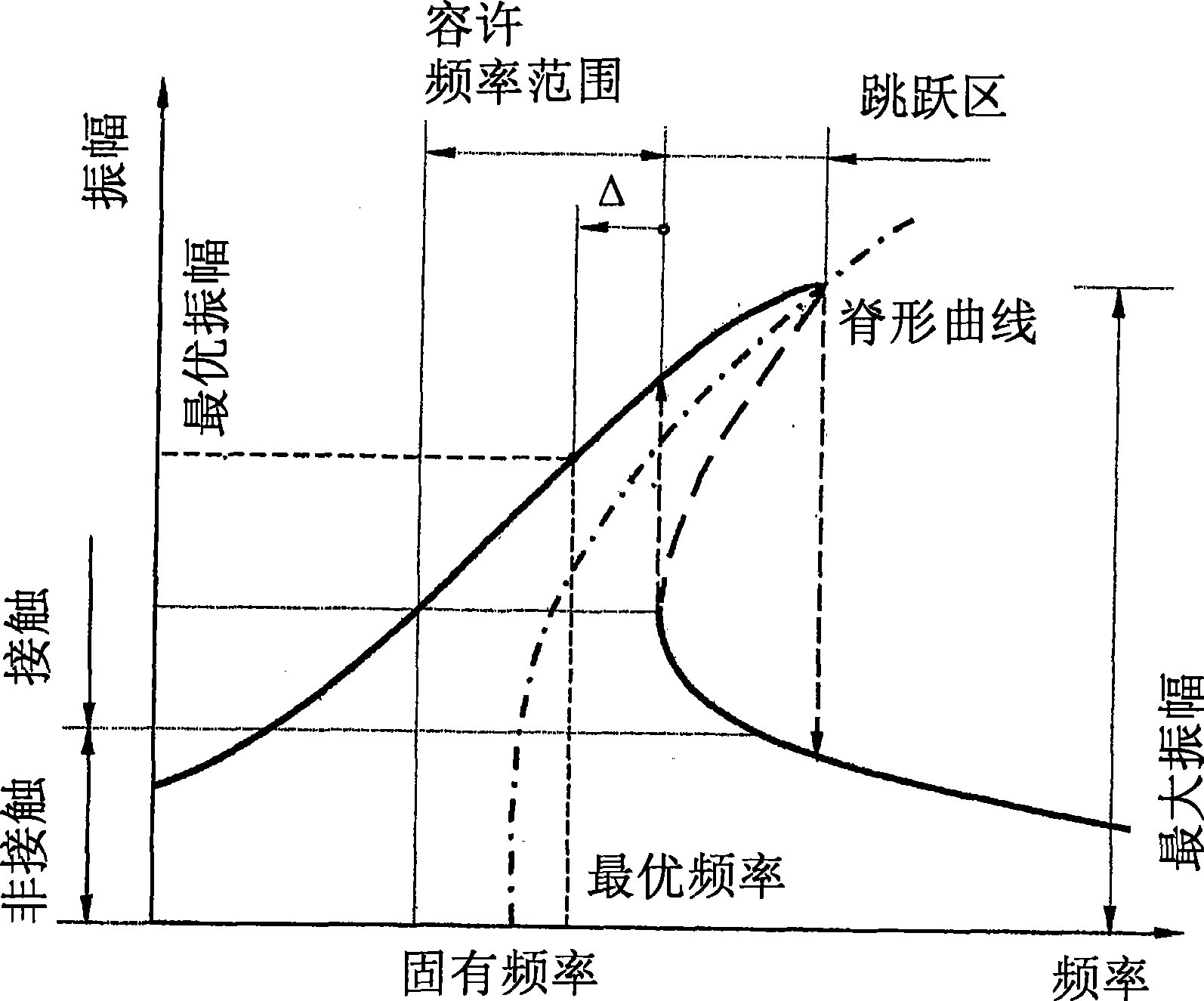

[0064] [0043] In a development of the present invention, it has been realized that particularly high drilling rates can be achieved when drilling through materials such as rock formations if the loading of the drill bit is arranged to induce resonance of the system formed by the drill bit and the formation being drilled .

[0065] [0044] However, while such resonances are obtainable on test rigs using standard samples, a different situation arises when drilling through natural rock formations. This is because drilling conditions vary from layer to layer within the formation. Consequently, the resonance conditions vary throughout the formation and therefore cannot be maintained throughout drilling.

[0066] [0045] The present invention overcomes this problem by identifying nonlinear resonance phenomena when drilling through material, and attempts to preserve the resonance in the system combined by the drill bit and the material being drilled.

[0067] [0046] To this end, Appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com