Metal oil tank production method

A production method and oil tank technology, applied in the field of mechanical processing, can solve problems such as uneven weld seams and inability to completely eliminate deformation, and achieve the effect of eliminating accumulated stress and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

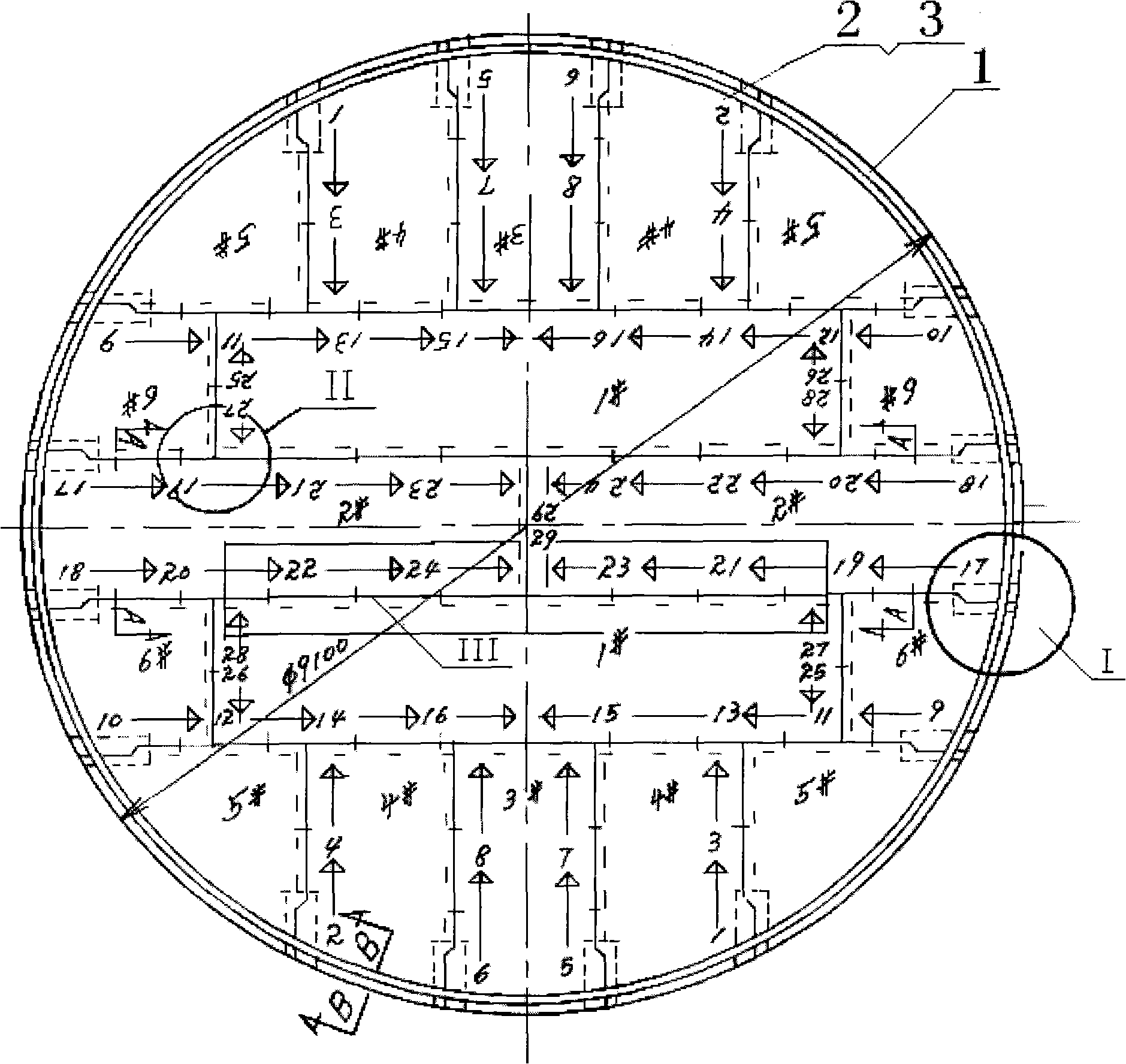

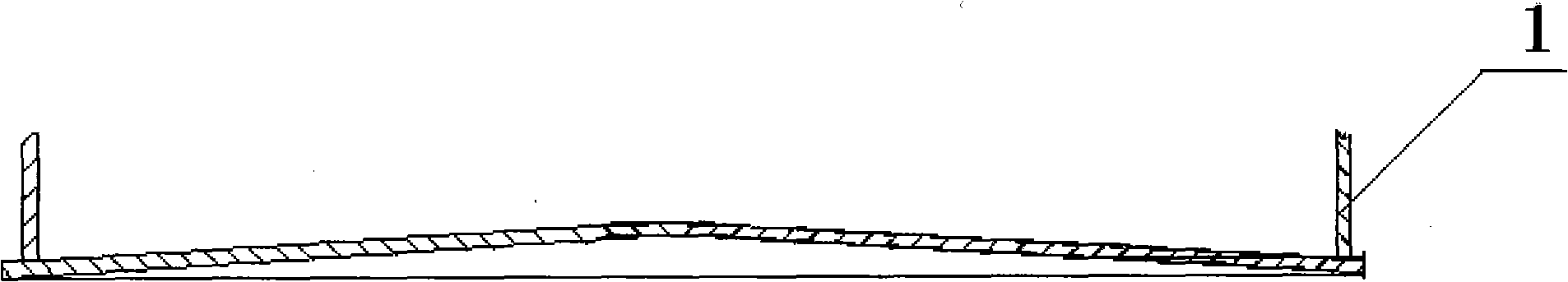

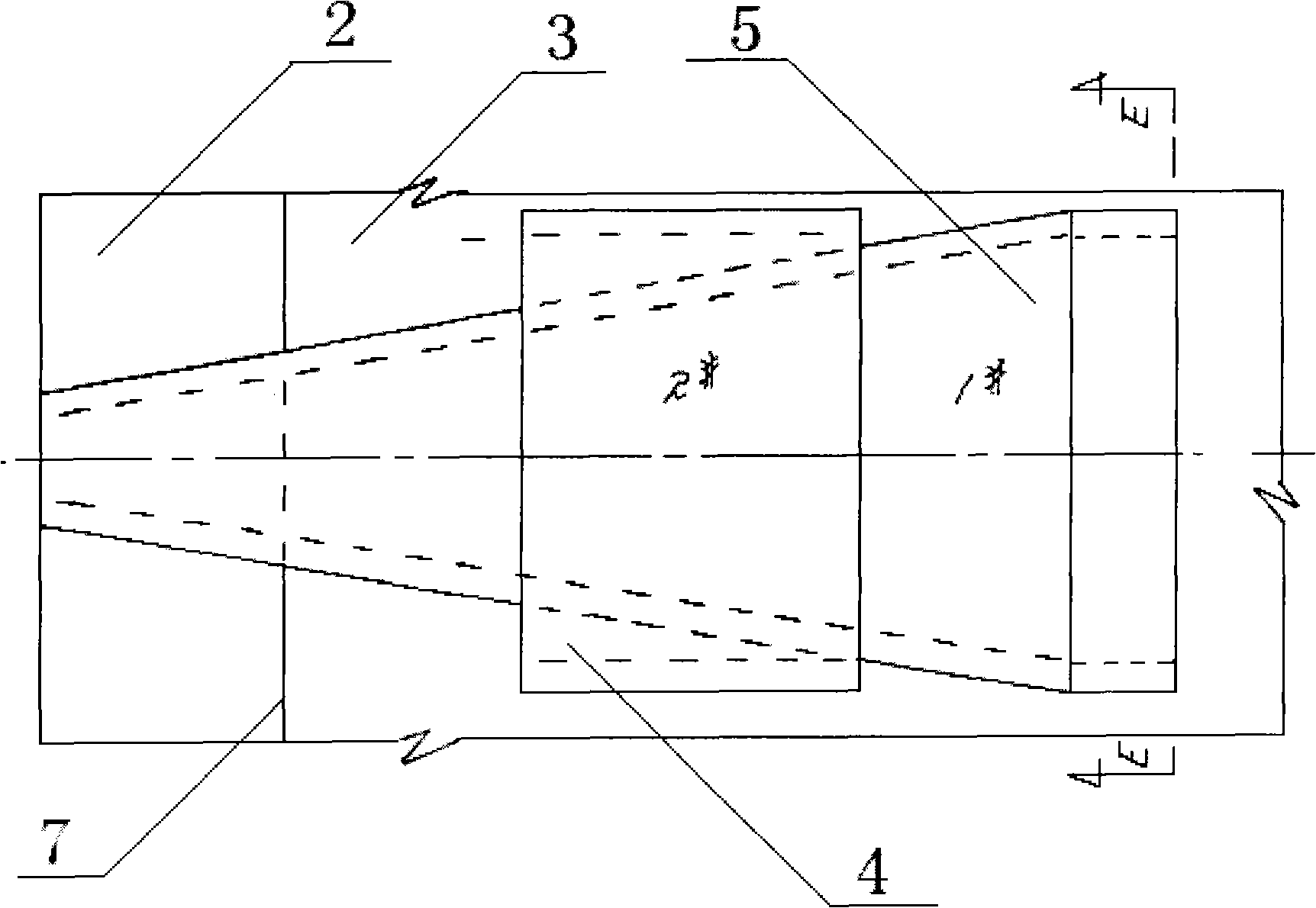

[0039] Such as figure 1 Shown, present embodiment tank volume V=500M 3 , height H=7980mm, tank bottom diameter Φ=9154mm, tank wall outer diameter Φ=9010mm. The material is A3F, the thickness of the tank wall steel plate is δ=5mm, and the thickness of the tank bottom steel plate is δ=7mm.

[0040] Calculation formula for bottom material of metal oil tank:

[0041] The first algorithm: when the outer diameter of the tank wall Φ is 9010mm,

[0042] Circumference = (9010+9010×6‰)×3.1416

[0043] =(9010+54.06)×3.1416

[0044] =9064.06×3.1416

[0045] =28475.65mm (circumference)

[0046] The second algorithm: when the outer diameter of the tank wall Φ is 9010mm,

[0047] Circumference=9010×3.1416×0.006+(9010×3.1416)

[0048] =28305.81×0.006+28305.81

[0049] =169.84+28305.81

[0050] =28475.65mm (circumference)

[0051] The actual cutting diameter of the bottom of the oil tank: when the circumference is 28475.65mm,

[0052] Φ=28475.65÷3.1416+(9100...

Embodiment 2

[0062] Present embodiment tank volume V=1000M 3 , height H=12690mm, tank bottom diameter Φ=11218mm, tank wall outer diameter Φ=11012mm. Material Q235-AF, Q235A, tank wall steel plate thickness δ=6mm, tank bottom steel plate thickness δ=6~7mm.

[0063] Calculation formula for bottom material of metal oil tank:

[0064] The first algorithm: when the outer diameter of the tank wall Φ is 11012mm,

[0065] Circumference = (11012+11012×8‰)×3.1416

[0066] =(11012+88.1)×3.1416

[0067] =11100.1×3.1416

[0068] =34872.1mm (circumference)

[0069] The second algorithm: when the outer diameter of the tank wall Φ is 11012mm,

[0070] Circumference=11012×3.1416×0.008+(11012×3.1416)

[0071] =34595.3×0.008+34595.3

[0072] =276.76+34595.3

[0073] =34872.1mm (circumference)

[0074] The actual cutting diameter of the bottom of the oil tank: when the circumference is 34872.1mm,

[0075] Φ=34872.1÷3.1416+(11130-11012)

[0076] =11100.1+118

[0077] =1...

Embodiment 3

[0085] Present embodiment tank volume V=2000M 3 , height H=11200mm, tank bottom diameter Φ=16076mm, tank wall outer diameter Φ=15830mm. Material Q235-AF, Q235A, tank wall steel plate thickness δ = 6-8mm, tank bottom steel plate thickness δ = 6-7mm.

[0086] Calculation formula for bottom material of metal oil tank:

[0087] The first algorithm: when the outer diameter of the tank wall Φ is 15830mm,

[0088] Circumference = (15830+15830×8‰)×3.1416

[0089] =(15830+126.64)×3.1416

[0090] =15956.64×3.1416

[0091] =50129.38mm (circumference)

[0092] The second algorithm: when the outer diameter of the tank wall Φ is 15830mm,

[0093] Circumference=15830×3.1416×0.008+(15830×3.1416)

[0094] =49731.53×0.008+49731.53

[0095] =397.85+49731.53

[0096] =50129.38mm (circumference)

[0097] The actual cutting diameter of the bottom of the oil tank: when the circumference is 50129.38mm,

[0098] Φ=50129.38÷3.1416+(15950-15830)

[0099] =15956.641+120

[0100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com