Wafer bearing device

A carrier device and wafer technology, applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as disconnection, out-of-focus, poor graphics, etc., to improve the manufacturing pass rate, reduce contact stress, and avoid breakage line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

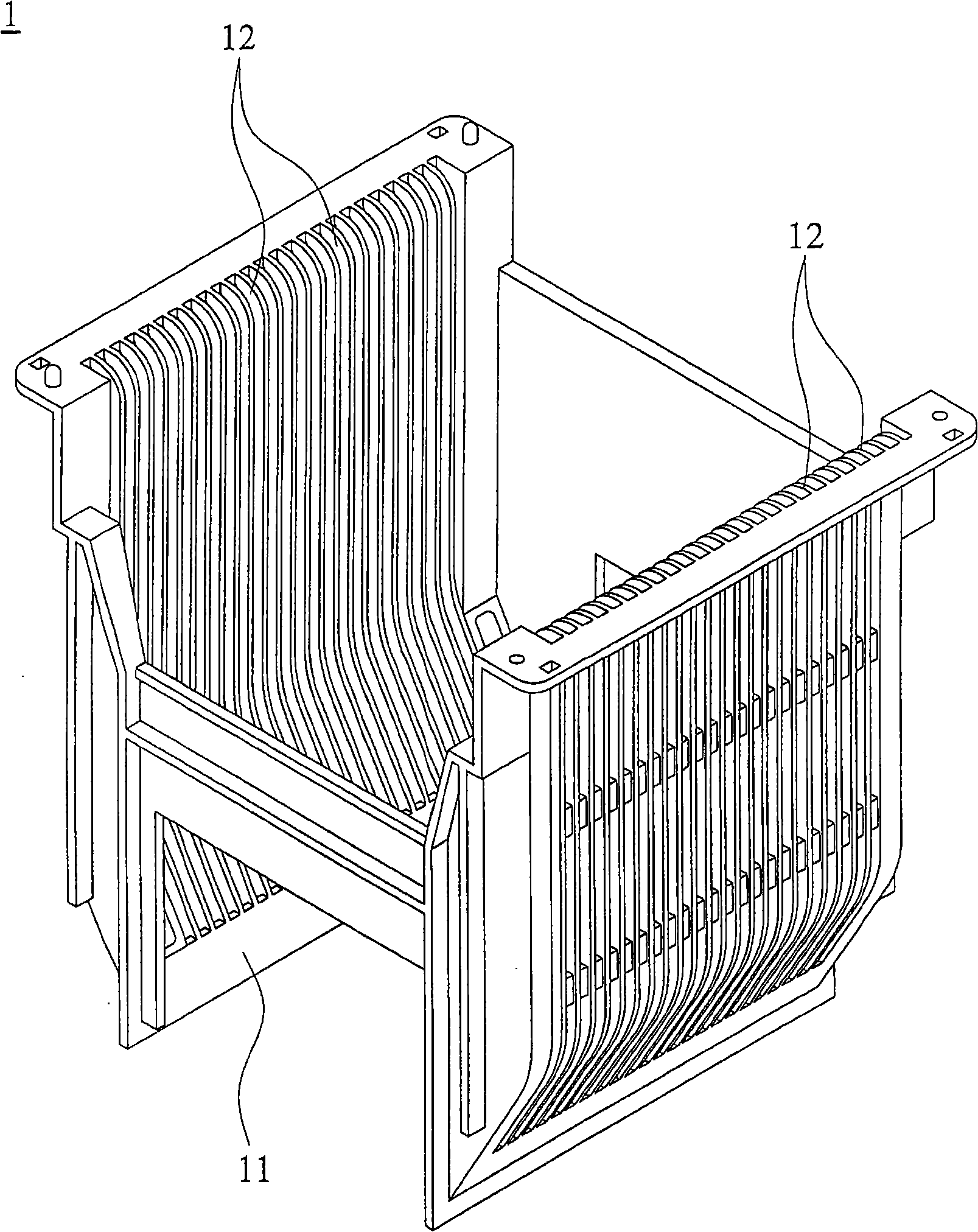

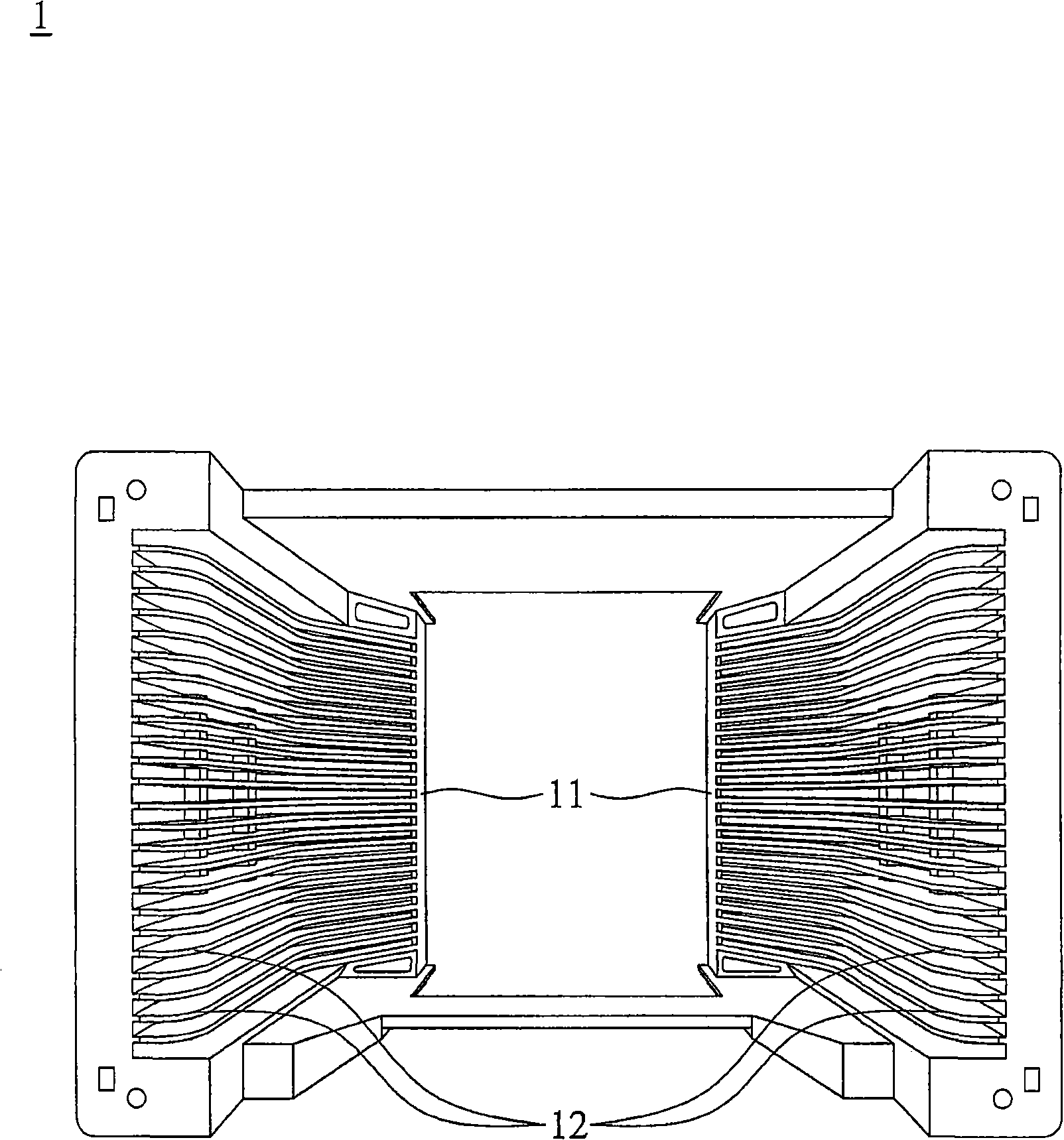

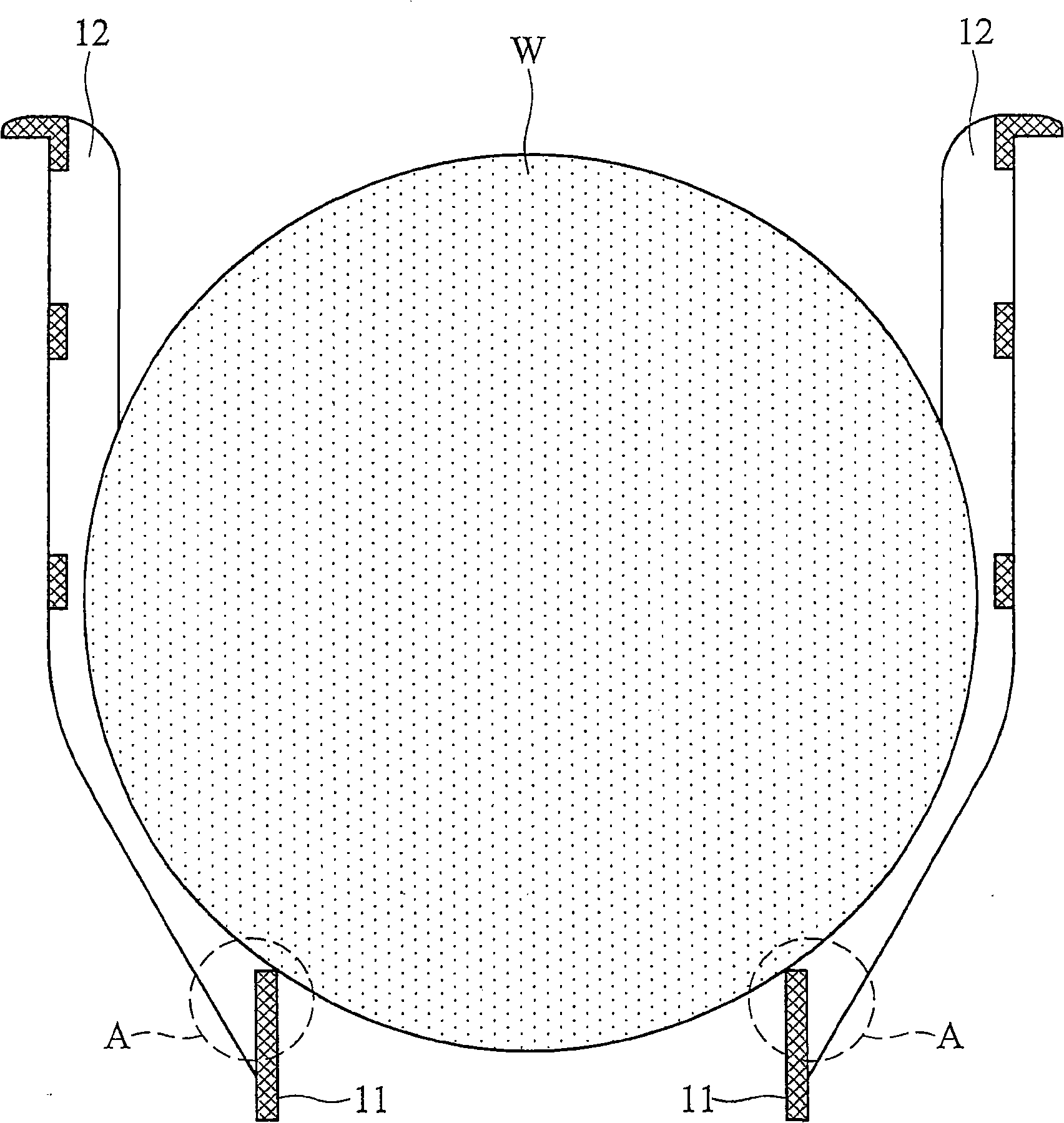

[0027] see Figure 3A and Figure 3B The wafer carrying device 100 of this embodiment may be made of PP or PEEK, etc., and mainly includes two opposite support rods 110 and a plurality of partition plates 120 .

[0028] Such as Figure 3B As shown, each support rod 110 has a multiple arc-shaped resisting portion 111 . In more detail, as Figure 4 As shown, each multi-arc abutting portion 111 has a first arc surface 111a, a second arc surface 111b and a third arc surface 111c, and the second arc surface 111b is connected to the first arc surface 111a and the third arc surface between faces 111c. In particular, the curvature direction of the second arc surface 111b is opposite to that of the first arc surface 111a, and the curvature direction of the third arc surface 111c is the same as that of the first arc surface 111a. In this embodiment, the shapes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com