Control method for laser drilling contraposition accuracy of high-density lamination circuit board

A technology of alignment accuracy and laser drilling, which is applied in multilayer circuit manufacturing, laser welding equipment, printed circuit manufacturing, etc. The problems of blind hole alignment are not uniform, so as to reduce the error, shorten the processing time and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

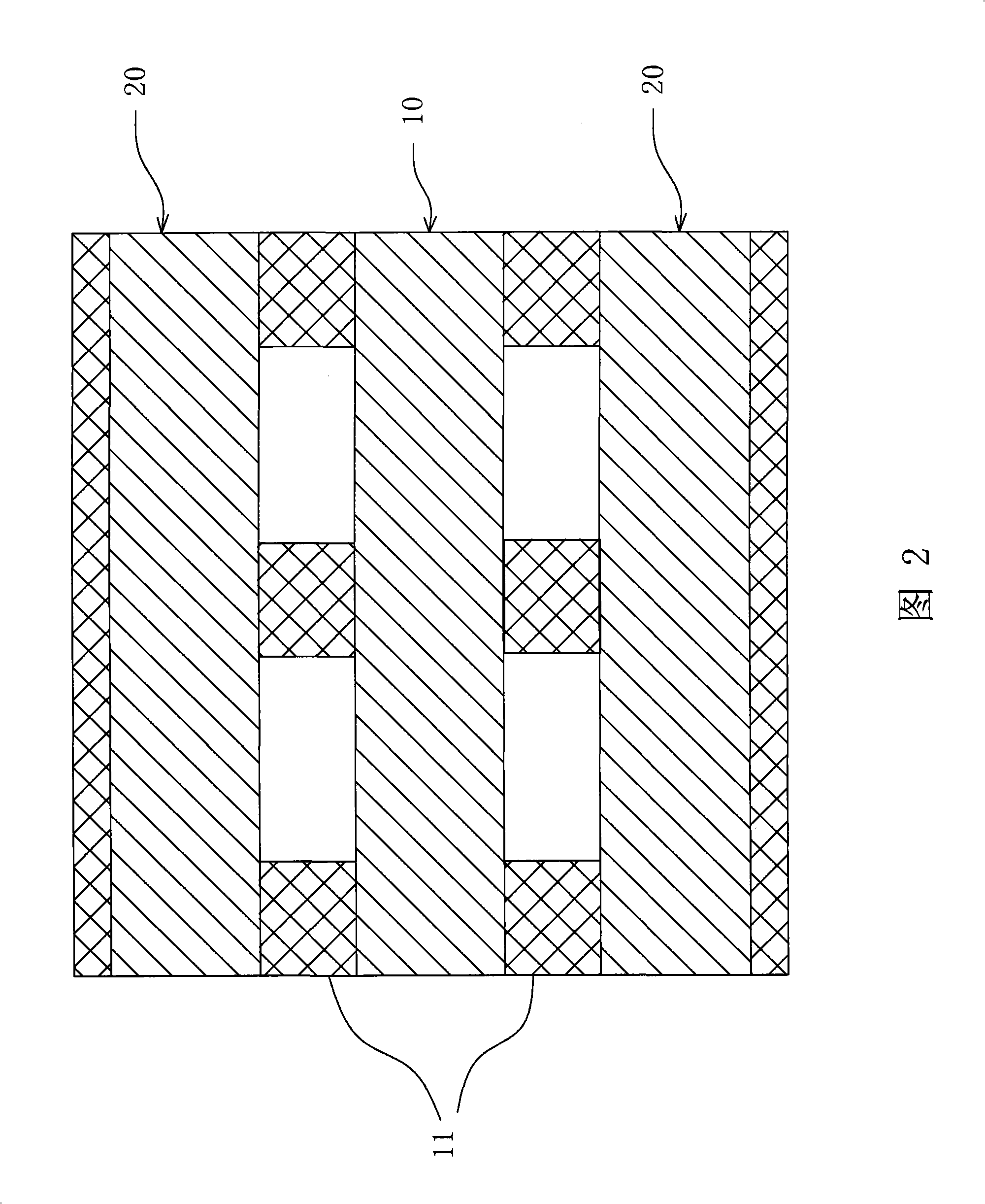

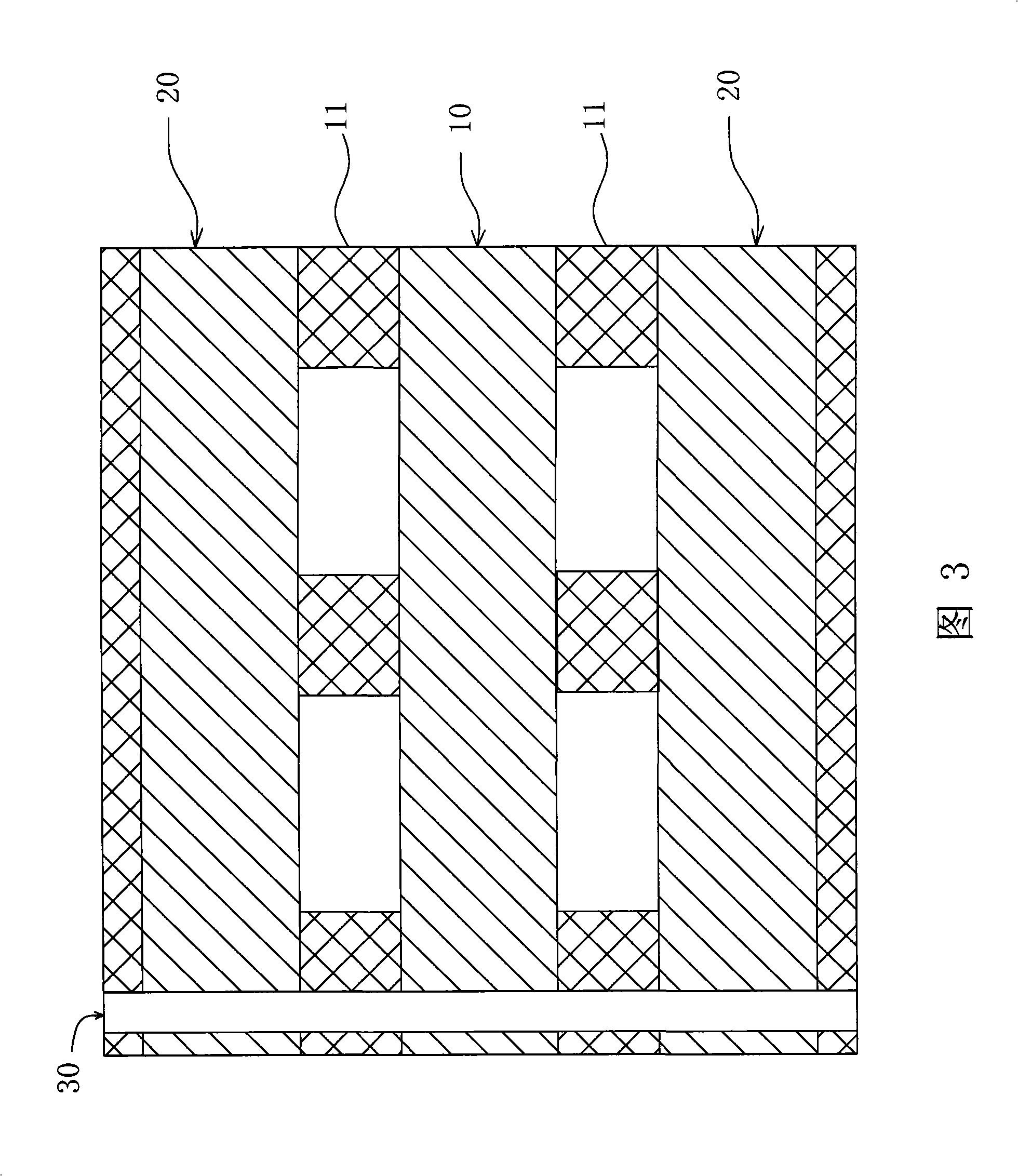

[0023] Referring to Figures 1 to 5, the alignment accuracy control method of laser drilling of a high-density laminated circuit board of the present invention is to keep the alignment center of the mechanical through hole of the high-density laminated circuit board consistent with the alignment center of the laser blind hole, so that The control method for controlling the alignment accuracy of drilling comprises the following steps:

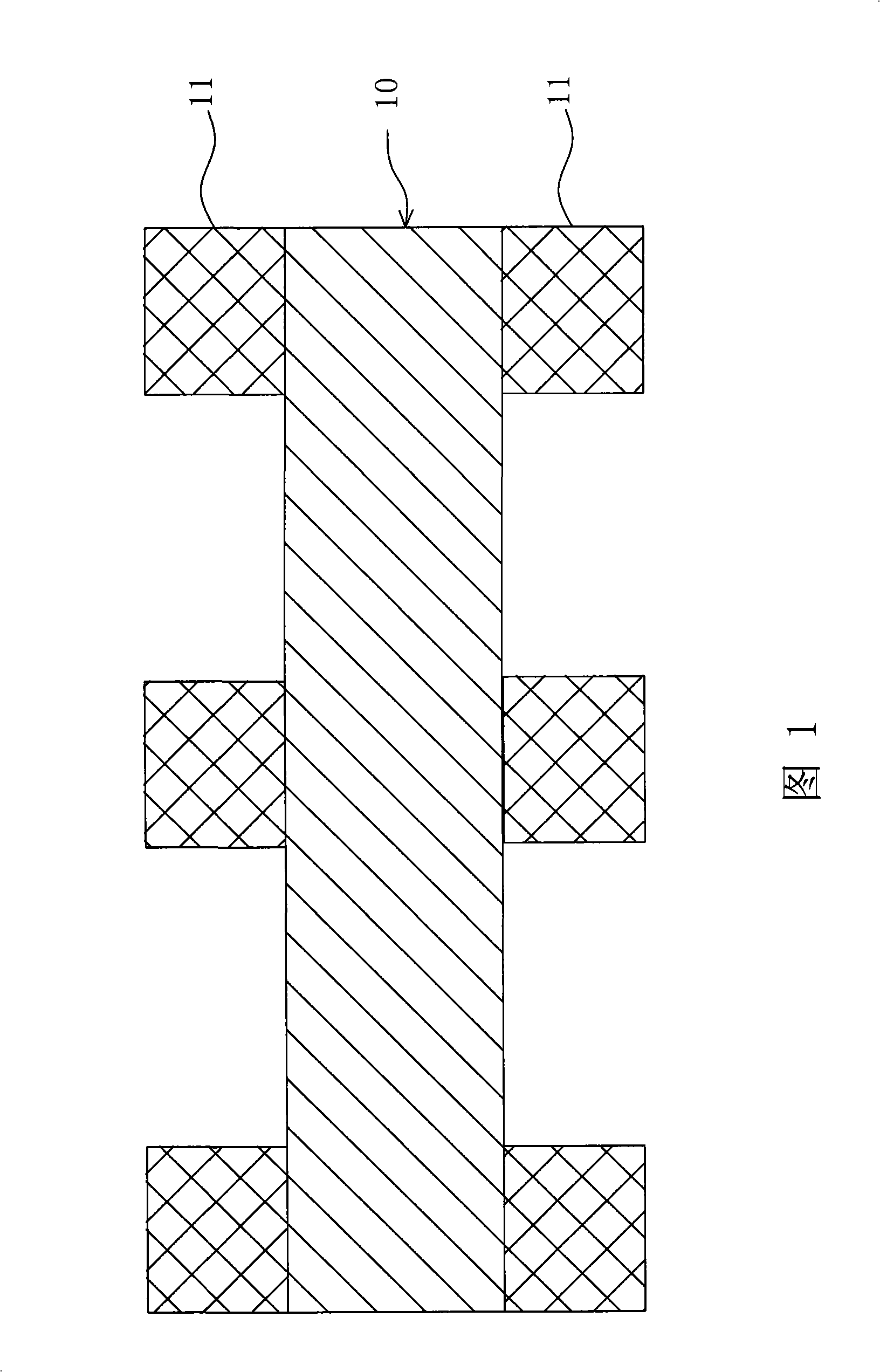

[0024] a. First, make a circuit board according to the conventional method, which is provided with a layer of electronic circuit on at least one side. The circuit board can be a single-sided or double-sided board, and the single-sided or double-sided board can be a single-layer, double-layer or multi-layer board, as shown in Figure 1, in this embodiment, the circuit board 10 is a doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com