Method and apparatus for the reliquefaction of a vapour

A reliquefaction, evaporative vaporization technology, applied in lighting and heating equipment, container discharge methods, liquefaction and other directions, can solve the problem of not significantly improving thermodynamic efficiency, and achieve the effect of improving thermodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

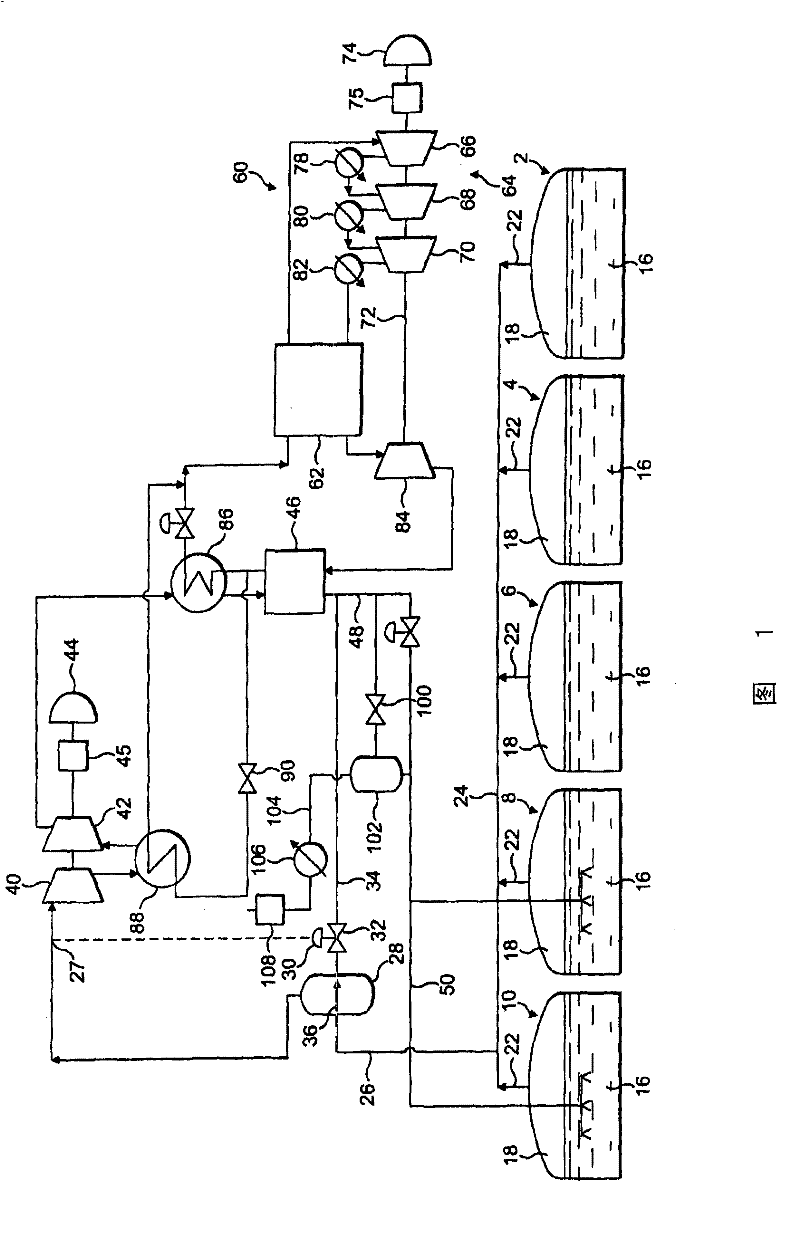

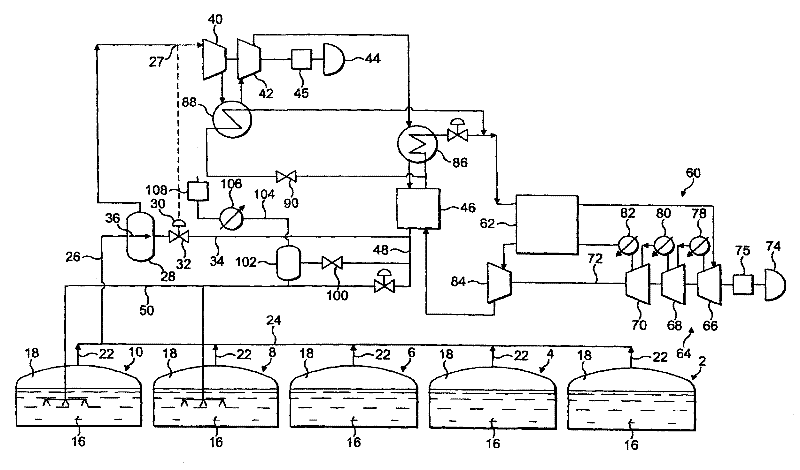

[0022] The figures are not drawn to scale.

[0023] Referring to the drawings, five insulated storage tanks 2, 4, 6, 8 and 10 are provided in the hull (not shown) of a seagoing vessel or other ocean-going vessel. Two or more of the storage tanks 2, 4, 6, 8 and 10 are provided with submerged orifice pipes 12 at their bottom regions through which LNG is introduced. The orifice pipes in tanks 2, 4 and 6 are not shown in the figure because of the simplicity of the figure. If only some storage tanks are provided with submerged orifices, redistribution of returned LNG to tanks not so provided is by operation of liquid pumps (not shown). In normal operation, the orifice tube 12 is submerged in a volume 16 of LNG. In each tank 2, 4, 6, 8 and 10 there is a vapor space 18 above a volume 16 of LNG.

[0024] Although the storage tanks 2, 4, 6, 8 and 10 are insulated, because the boiling point of LNG at normal pressure is much lower than the ambient temperature, in each storage tank 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com