Method of sterilizing liquid and liquid food

A liquid food, pulse technology, applied in food science and other directions, can solve the problems of difficult quality deterioration and lowering of liquid food sterilization temperature, and achieve the effect of inhibiting flavor and rapid sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] The following examples illustrate the present invention more specifically, but the present invention is not limited to these examples.

Embodiment and

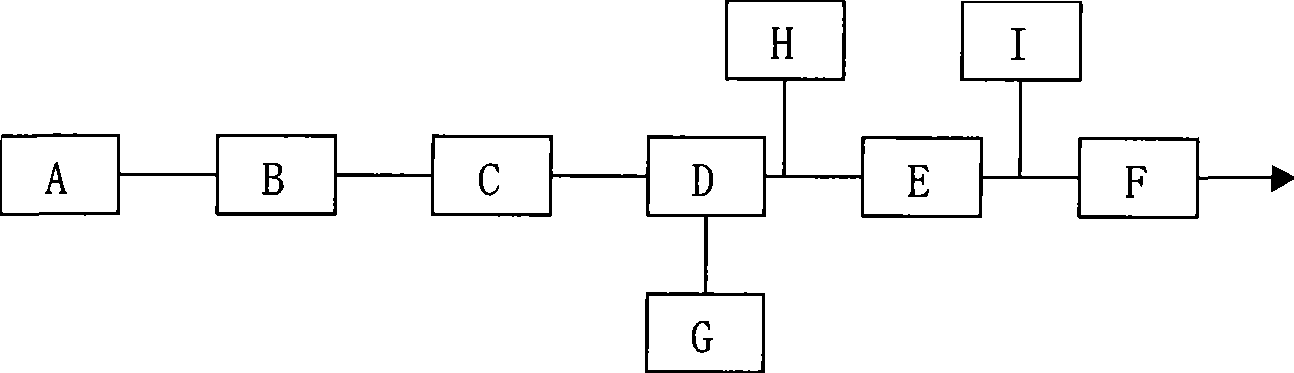

[0050] The following examples and comparative examples 2 and 3 use the configuration of A to I except C (temperature adjustment means) figure 1 Device to implement. The details of the device are as follows.

[0051] A glass beaker or a stainless steel container is used for the storage of the liquid sample. As a pump that quantitatively feeds a liquid sample, a diaphragm type digital quantitative pump or a screw pump is used. The power supply that generates high electric field pulses uses a supersaturated magnetic switch compression type power supply structure in order to apply a high voltage with a high repetition frequency. The maximum repetition frequency is 400 Hz. The power supply is connected to the application part that applies the high-voltage pulse to the liquid sample, and a pair of opposed flat electrodes made of stainless steel and an insulating spacer made of polyethersulfone are combined to form a flow path. The storage volume of the liquid food material in the flow ...

Embodiment 1

[0054] (1) Preparation of suspension sample

[0055] After adding trisodium citrate dihydrate to ultrapure water to make an electrolyte solution with a conductivity of 120mS / m at 20°C, add bacterial spores (Bacillus subtilis: Bacillus subtilis ), prepare a suspension sample containing bacterial spores (spore concentration: 6.5×10 6 CFU / mL).

[0056] (2) Sterilization

[0057] The suspension sample prepared in (1) was processed using the apparatus described above.

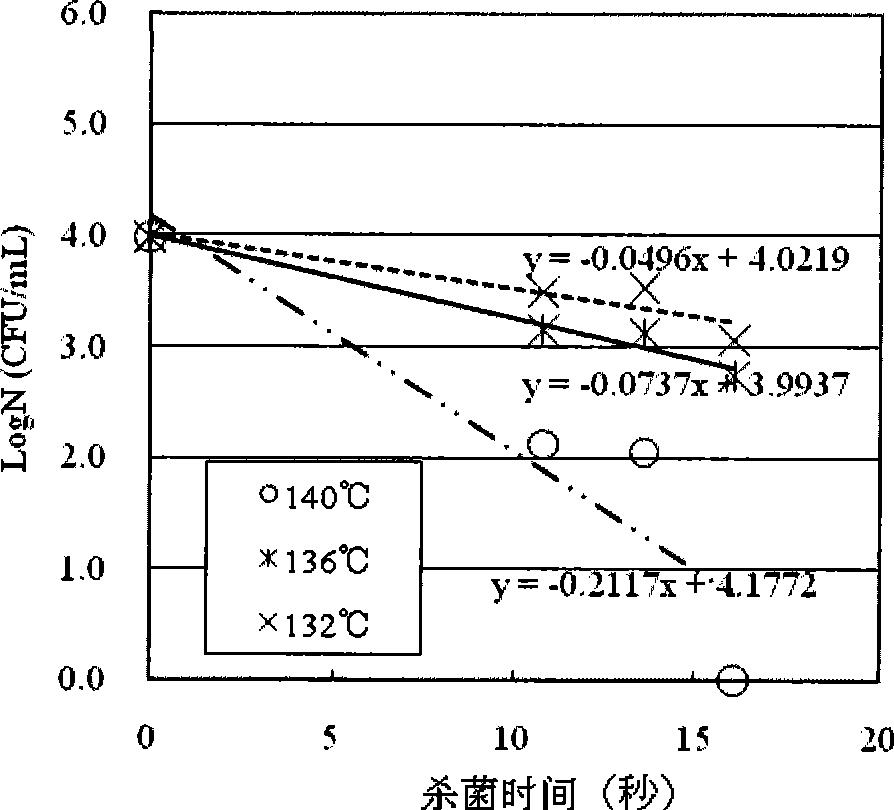

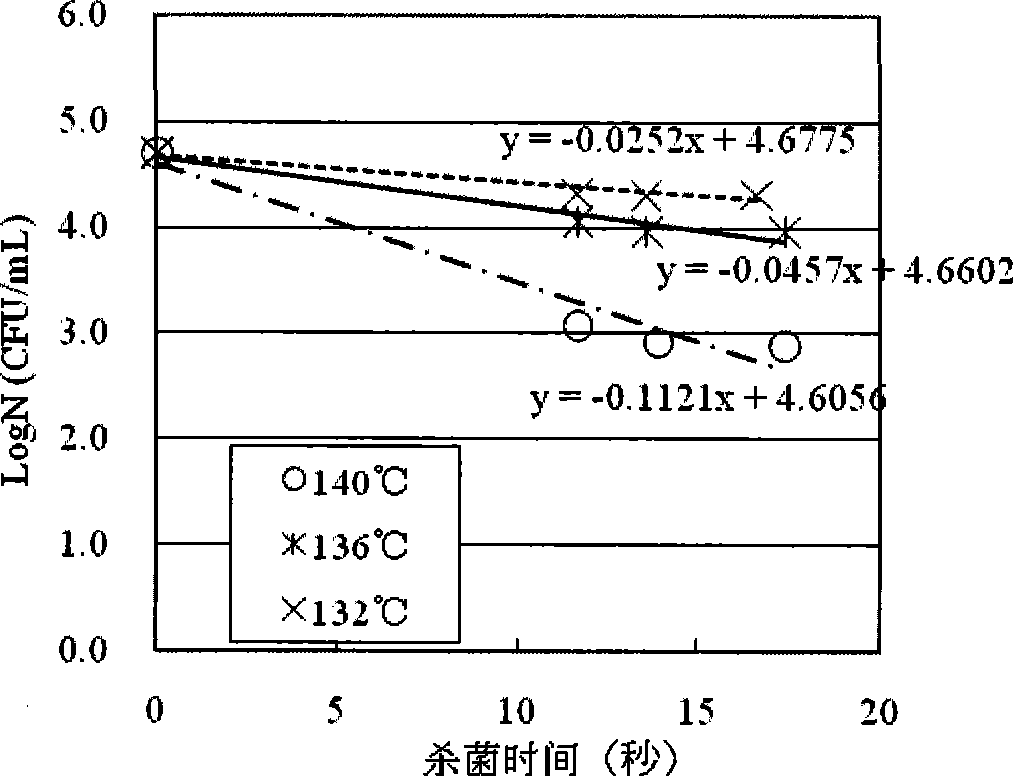

[0058] (A) Use a pump to continuously pass a suspension sample at about 20°C into the application section (liquid passing rate: 11 mL / min). Next, in the application section, a high electric field pulse with a pulse width of 100 ns, a pulse rise time of 50 ns, and an electric field intensity of 98 kV / cm was applied 500 times at a repetition frequency of 100 Hz. The temperature of the suspension sample immediately after flowing out from the application part, that is, the predetermined temperature, was 105°C, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com