Method for removing fluorine residue in manufacture process of semi-conductor

A semiconductor and process technology, applied in the field of removing fluorine residues in semiconductor manufacturing processes, can solve the problems of wafer crystal defects and fluorine residues have no special effect, and achieve the effect of avoiding crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

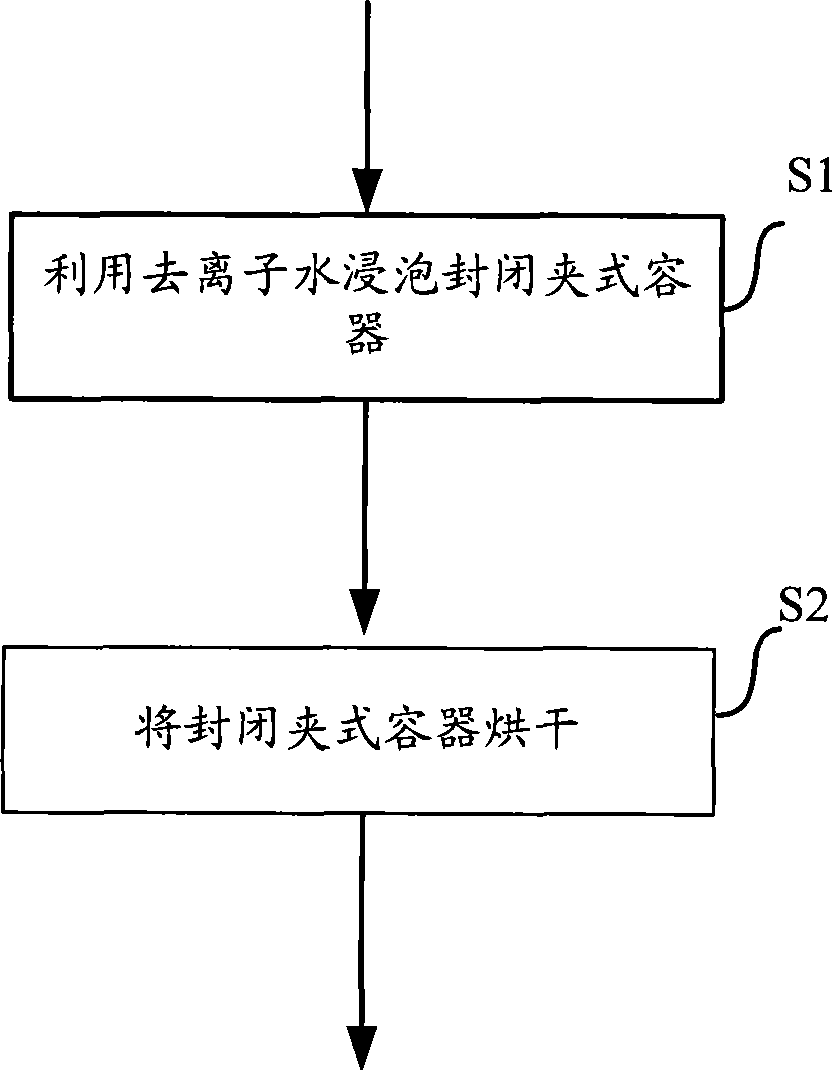

[0023] In this embodiment, what is removed is the fluorine residue on the crystal box. The temperature for soaking the crystal box with deionized water is 70°C, and the time for soaking the crystal box with deionized water is 9 hours.

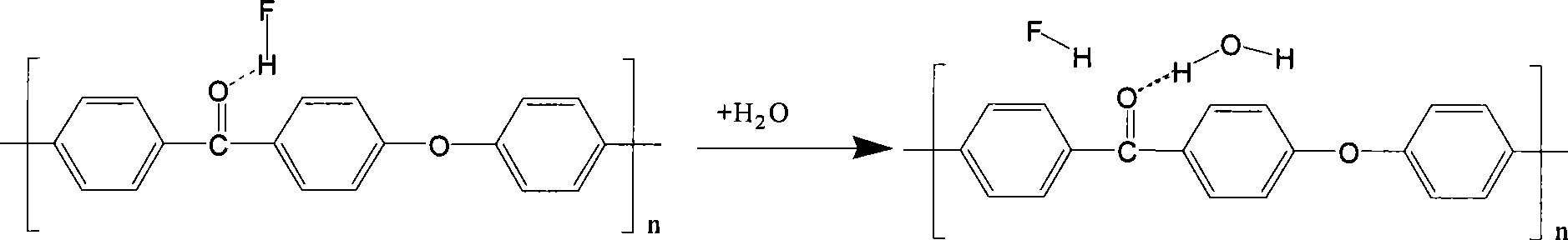

[0024] In this embodiment, the chemical reaction equation for soaking the crystal box with deionized water is:

[0025]

[0026] Through electron microscope observation, using the method of this embodiment, adsorbed F - The amount of Poly-ether-ether-ketone decreased by 95%. This fully illustrates the superiority of the present invention.

Embodiment 2

[0028] In this embodiment, what is removed is the fluorine residue on the crystal box. The temperature for soaking the crystal box with deionized water is 110° C., and the time for soaking the crystal box with deionized water is 22 hours.

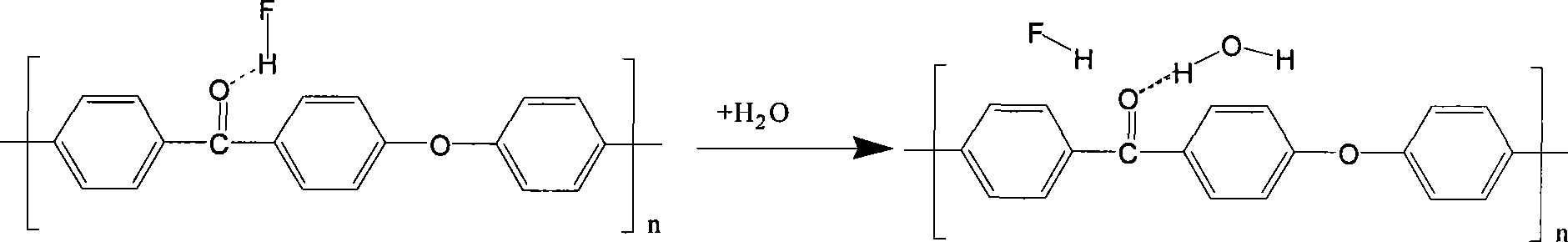

[0029] In this embodiment, the chemical reaction equation for soaking the crystal box with deionized water is:

[0030]

[0031] According to electron microscope observation, the amount of Polyetheretherketone adsorbed F- was reduced by 99% by using the method of this embodiment. This fully illustrates the superiority of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com