Vertical vortex generator

A vortex generator and the same technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of non-separated flow negative effects, complex structure, and inability to generate eddy currents, etc., and achieve simple structure, convenient change, and convenient vortex intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

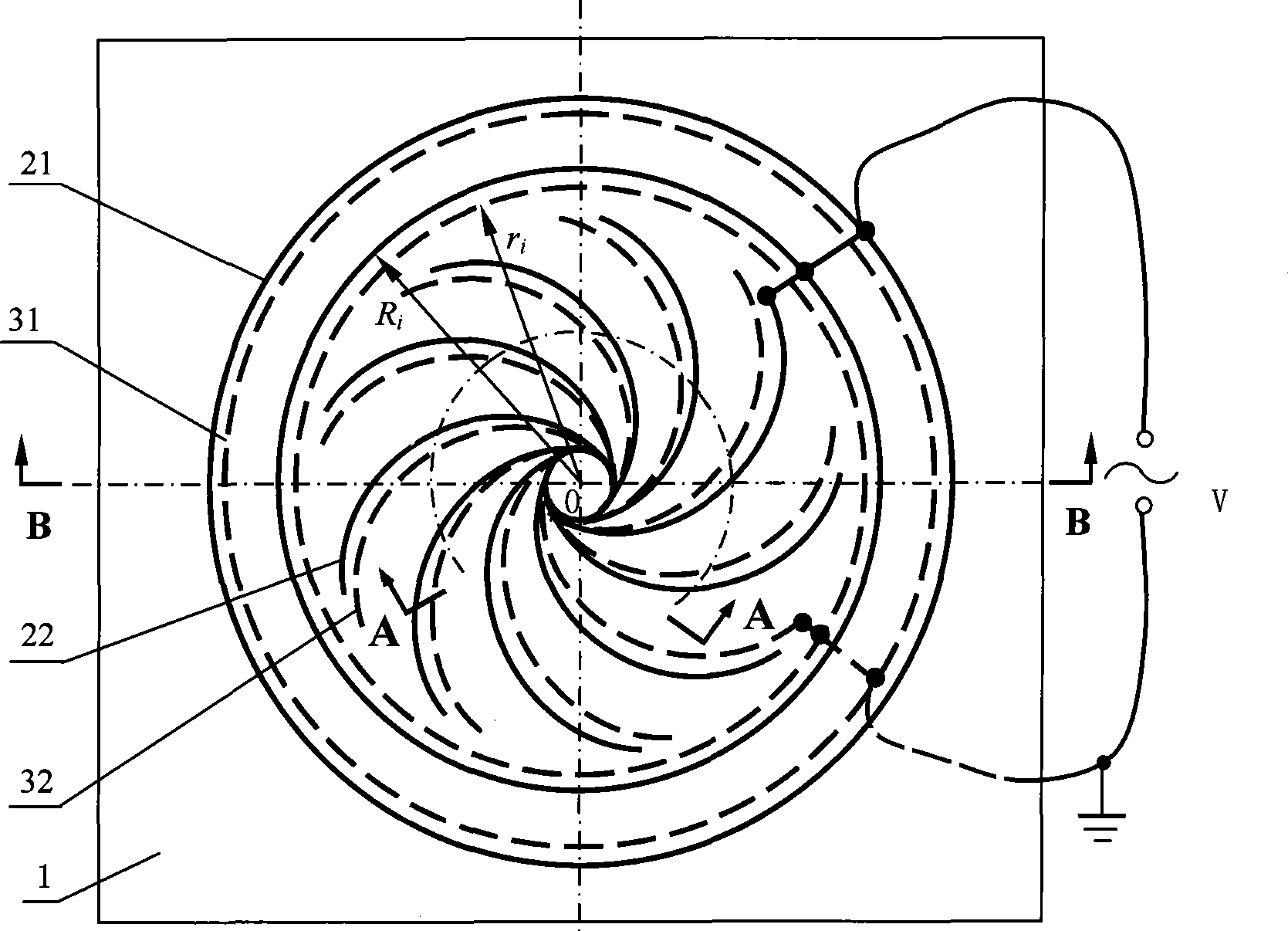

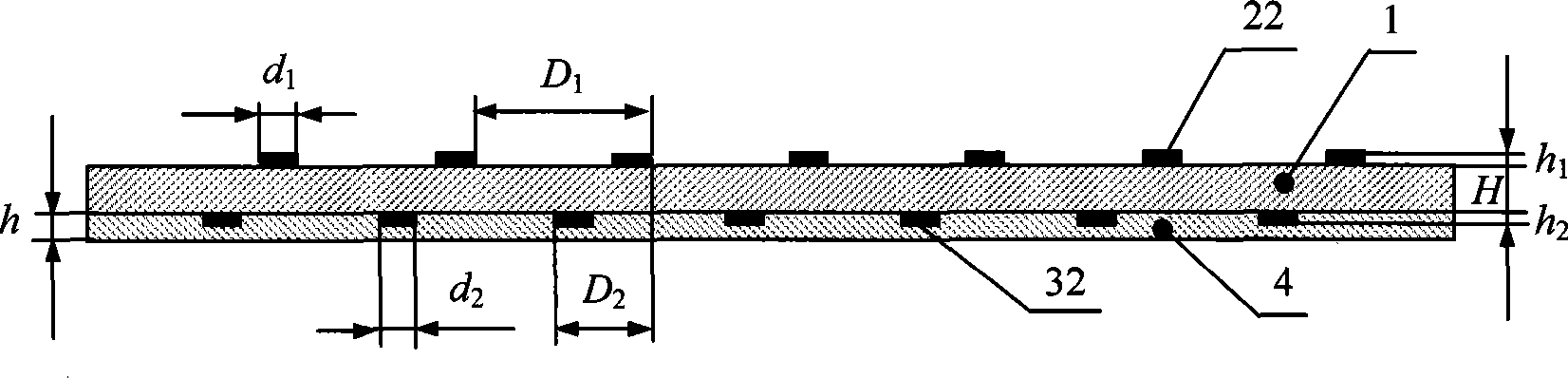

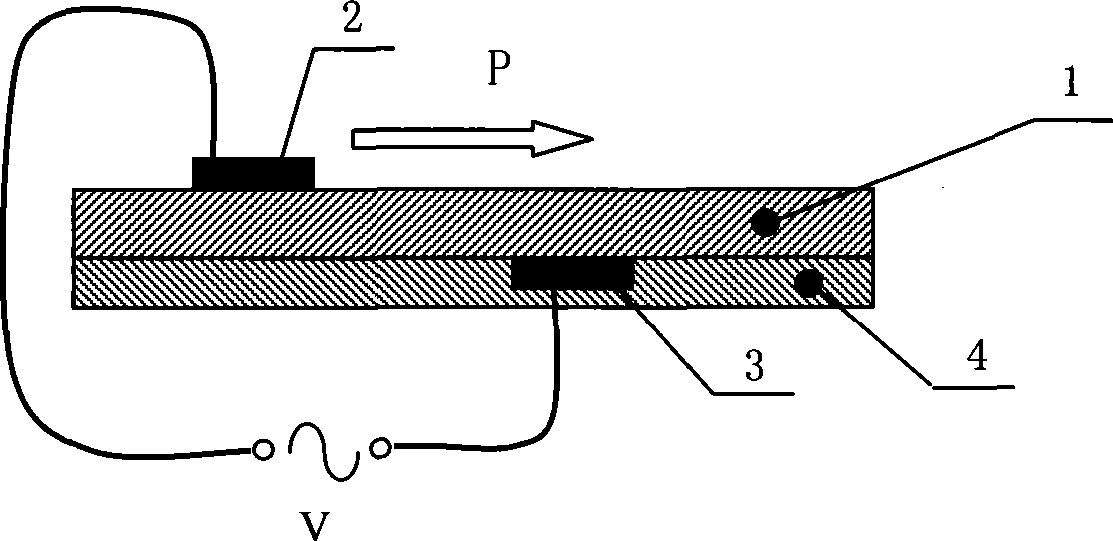

[0024] See eg figure 1 and 2As shown, the embodiment of the present invention is provided with a base plate 1 and a high-voltage AC power supply V; the base plate 1 is an insulating dielectric plate, and the insulating dielectric plate is selected from a ceramic plate, a polytetrafluoroethylene plate, or an epoxy resin plate. The upper surface and the lower surface of the base plate 1 are covered with 3 pairs of concentric circular upper surface electrodes 21 and circular lower surface electrodes 31, and 9 pairs of arc-shaped upper surface electrodes 22 and arc-shaped lower surface electrodes 32; The circular upper surface electrodes 21 and the circular lower surface electrodes 31 outside the surface electrodes 22 and the arc-shaped lower surface electrodes 32 are alternately arranged, and the arc-shaped upper surface electrodes 22 and the arc-shaped lower surface electrodes 32 are along the circumferential direction of the circular electrode in the center of the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com