Prestress steel pipe

A pre-stressed steel wire, pre-stressed technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of increased difficulty in transportation and construction, short service life of steel pipes, and increased replacement costs. Improve the ability to resist uneven settlement, prolong the service life, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

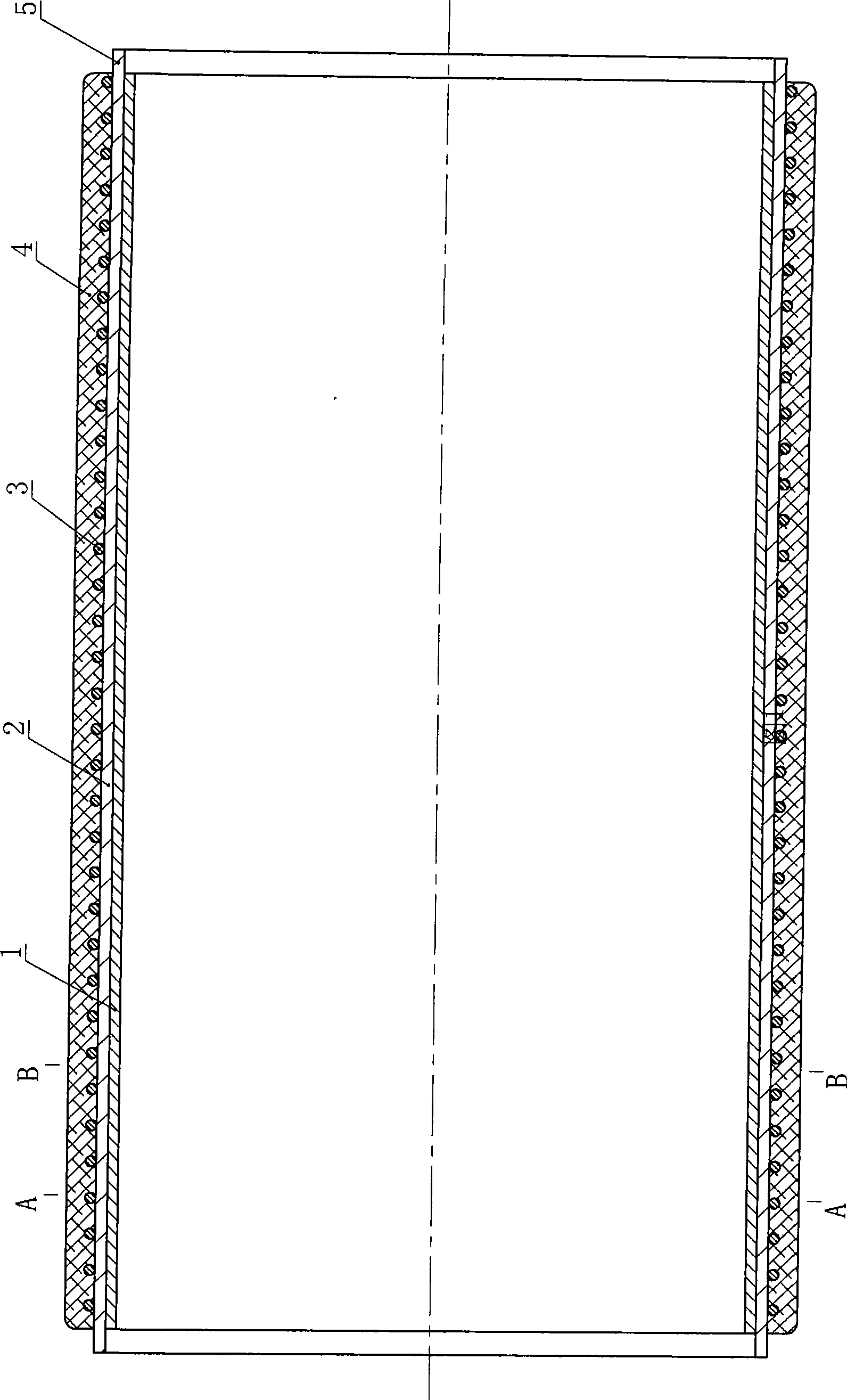

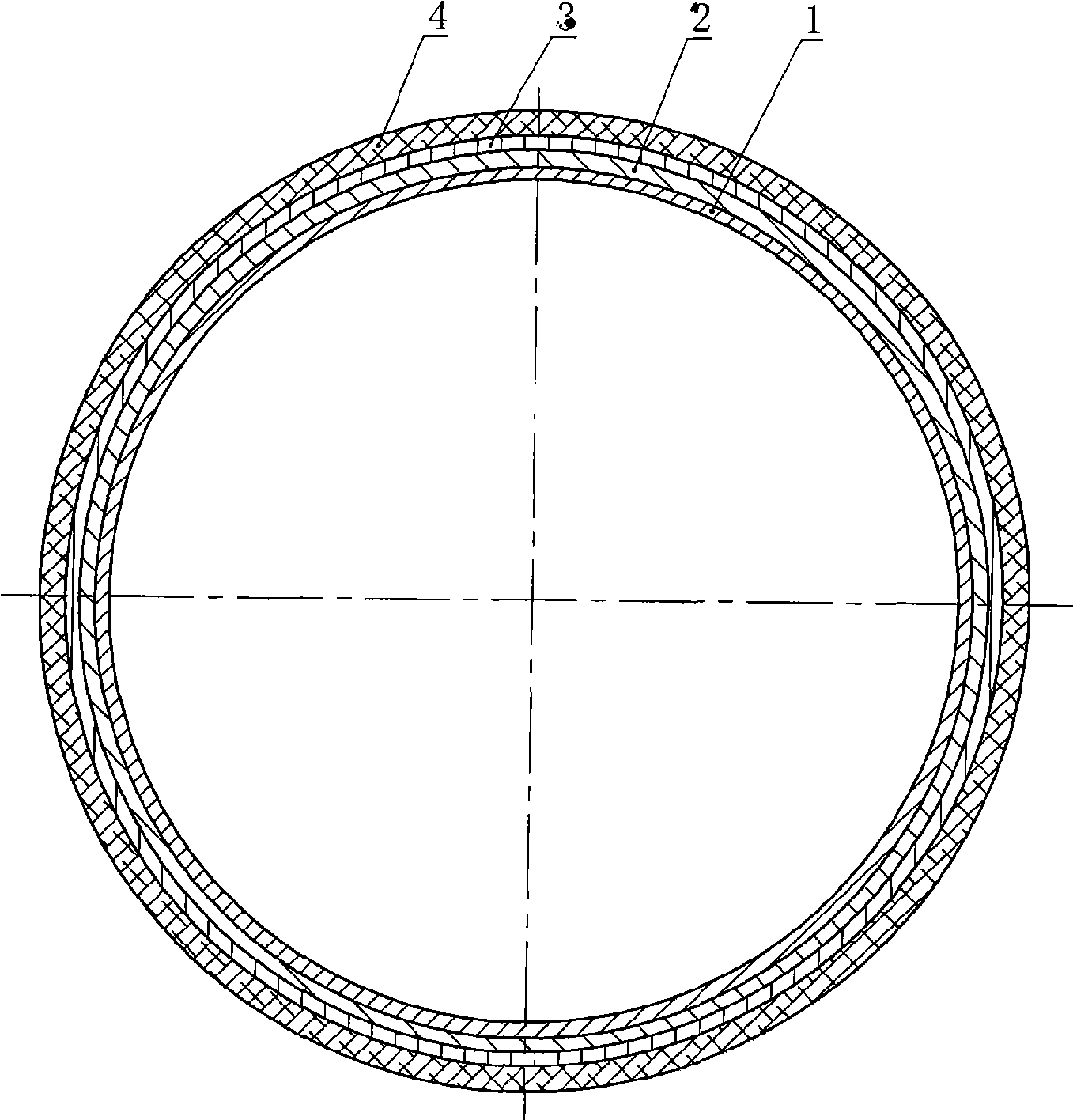

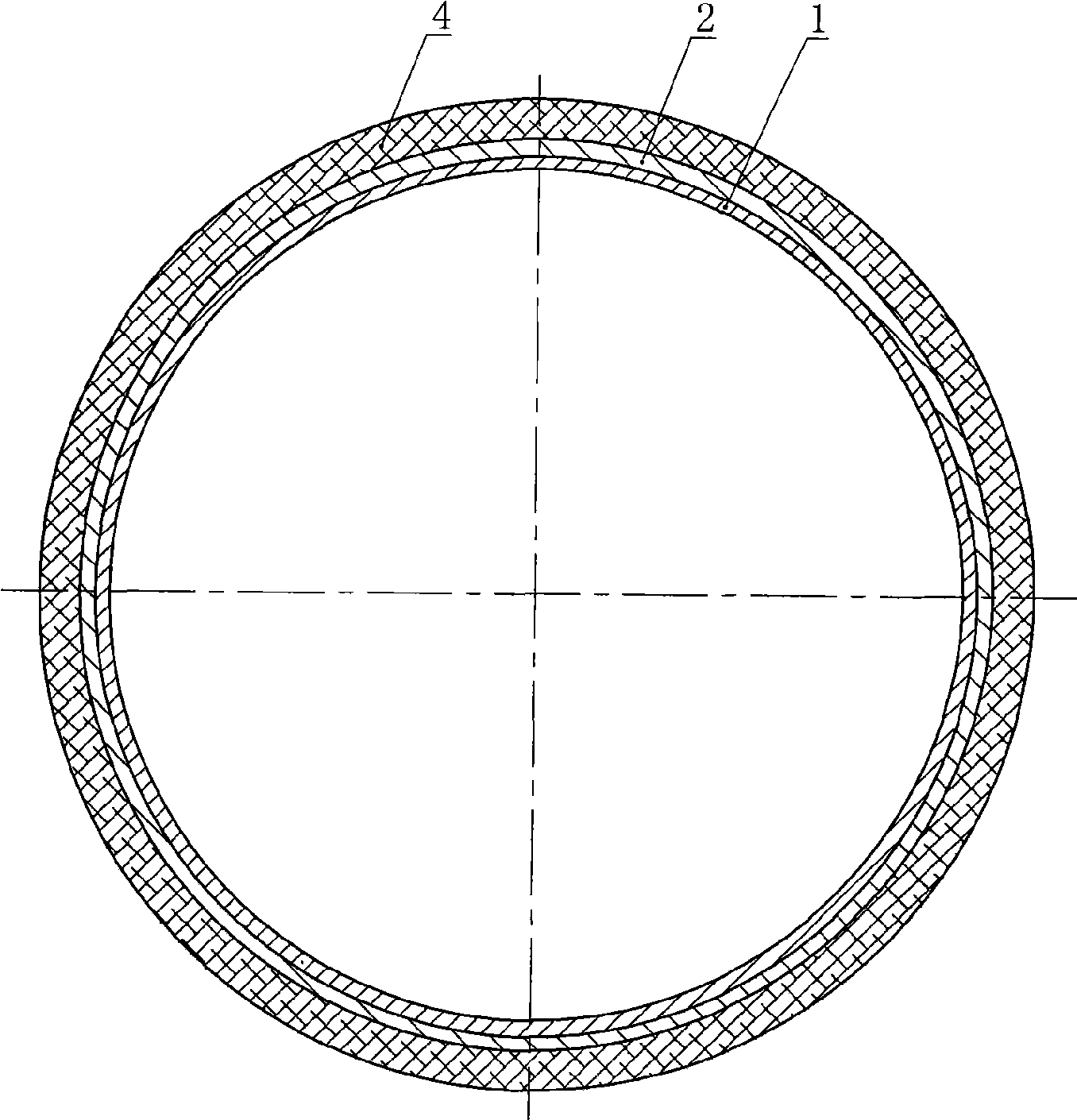

[0018] A prestressed steel pipe, the pipe body 2 is a steel pipe body, and an inner lining layer 1 is coaxially fixed on the inner wall of the pipe body, and the inner lining layer is made of glass fiber reinforced plastic or polyurethane material; A protective layer 4 is installed, and the protective layer adopts polyurethane or fiberglass. Under normal circumstances, the materials used for the lining layer and the protective layer should be different, such as fiberglass for the inner lining layer, and polyurethane for the protective layer. Prestressed steel wires 3 are wound on the outer wall of the pipe in the protective layer, and the wound prestressed steel wires are 1-3 layers, and the drawings of this embodiment show one layer.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap