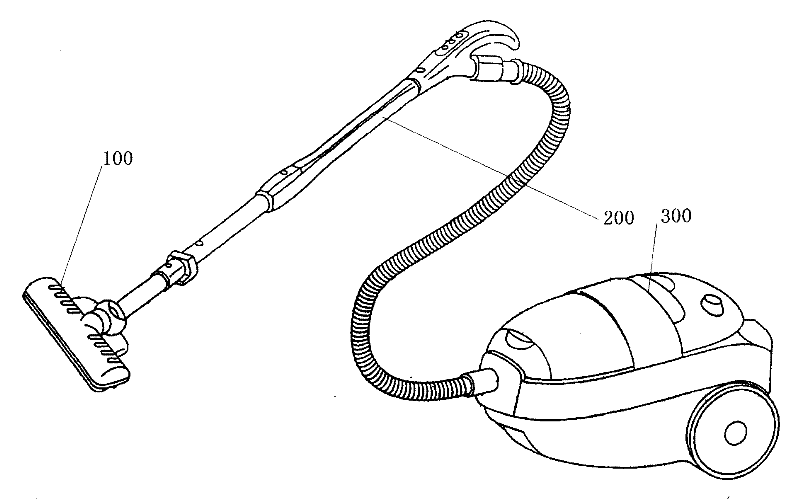

Vacuum cleaner floor brush and vacuum cleaner with the vacuum cleaner floor brush

A technology of vacuum cleaner and rolling belt, which is applied in the field of vacuum cleaner with the floor brush of the vacuum cleaner, can solve the problems of cumbersome use process, affecting air fluidity, and difficulty in fully utilizing the vacuum degree, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

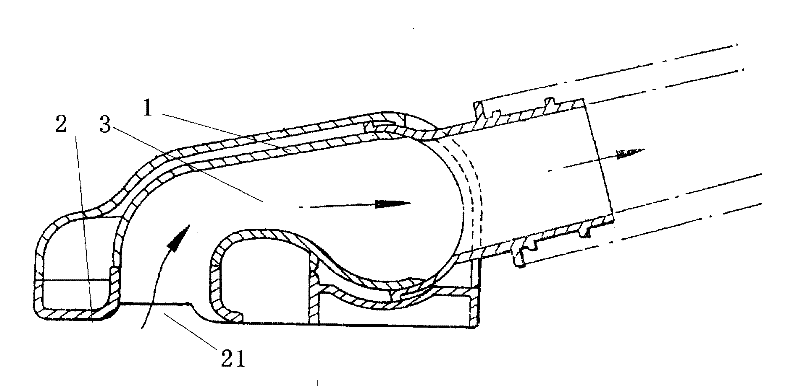

[0049] combine Figure 4 to Figure 5 The floor brush of the vacuum cleaner provided by Embodiment 1 includes an upper cover 1, a bottom plate 2, a front rolling shaft 22, a rear rolling shaft 23, a left side plate 24 and a right side plate 25, and the upper cover 1 and the bottom plate 2 are fixed to form a Suction chamber 3.

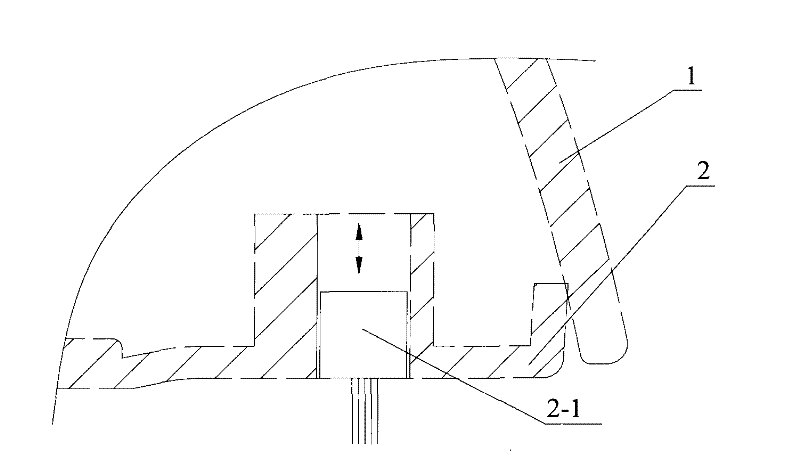

[0050] give together Figure 5 and Figure 6 , the left side plate 24 and the right side plate 25 also include two side bearings 25-1, middle part 25-2, endless rolling belt 25-3 and needle roller 25-4 respectively, and the two side bearings 25 -1 axes are parallel or substantially parallel, and are installed on the base plate 2, and the middle part 25-2 is fixed to the base plate 2. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com