Control device for oxygenation intermittent coal gas preparation

A control device, intermittent technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of high real-time performance, strong anti-virus ability, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

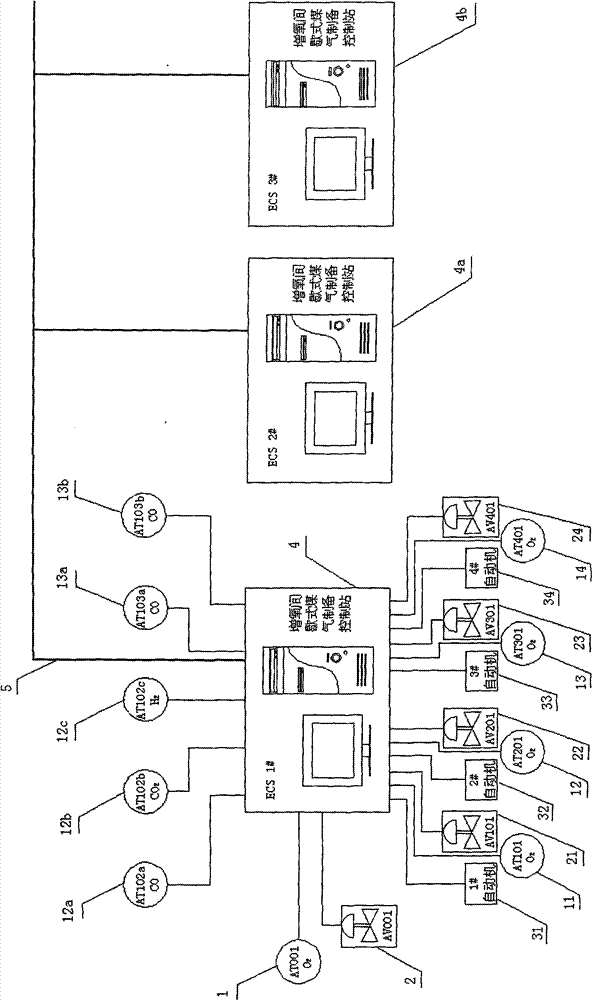

[0102] An oxygen-increasing intermittent gas preparation control device, including an air compression tank, a gas generator and a control system, in the control system:

[0103] The embedded control station 4 is respectively connected with the magnetic oxygen analyzer 1 and the pneumatic film regulating valve 2, and the magnetic oxygen analyzer 1 and the pneumatic film regulating valve 2 are connected with the air mixing tank;

[0104] The embedded control station 4 is respectively connected with the magnetic oxygen analyzer 11, the pneumatic film regulating valve 21, and the automatic machine 31, and the magnetic oxygen analyzer 11, the pneumatic film regulating valve 21, and the automatic machine 31 are all connected with the No. 1 gas generator;

[0105]The embedded control station 4 is respectively connected with the magnetic oxygen analyzer 12, the pneumatic film regulating valve 22, and the automatic machine 32, and the magnetic oxygen analyzer 12, the pneumatic film regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com