Oxygenation intermittent coal gas preparation

A technology of oxygen amount and gasification gas, which is applied in the field of fixed-bed intermittent gas preparation, can solve the problems of low oxidation combustion speed, long time, slow heating speed, etc., and achieve the goal of increasing gas production time, increasing composition and reducing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

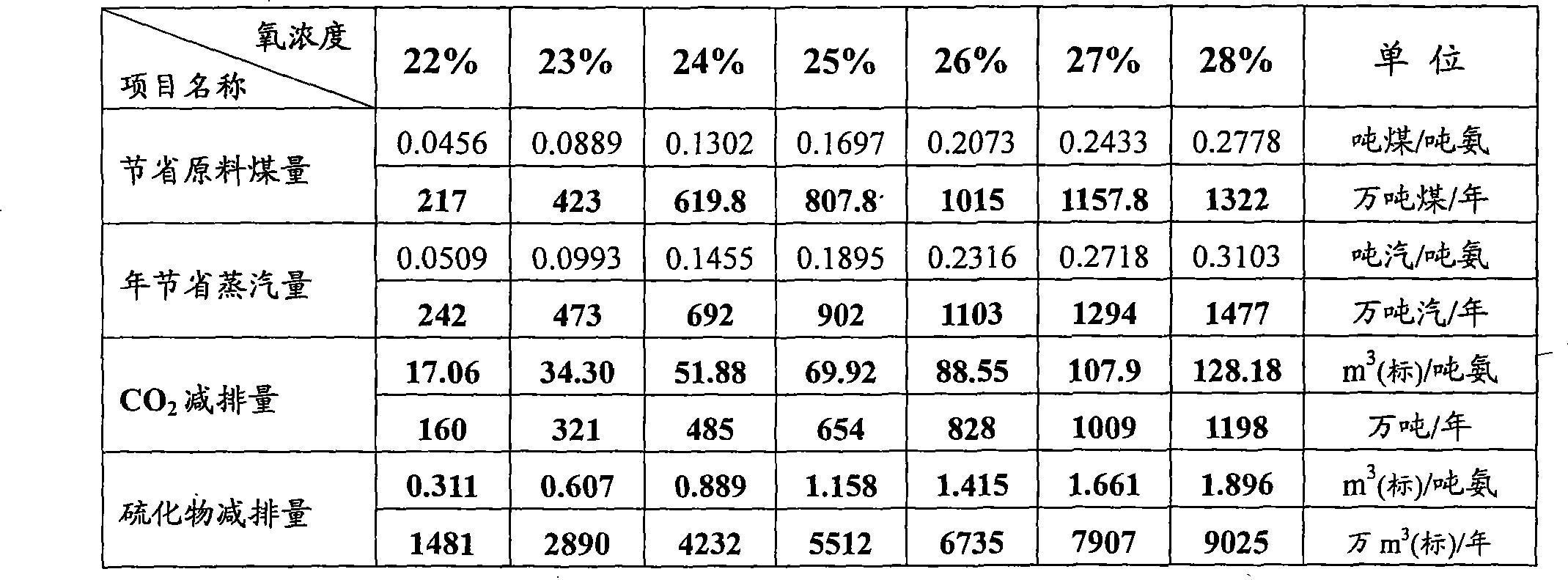

[0068] The invention relates to an oxygen-increasing intermittent coal gas preparation method, the steps of which are actually two steps of heating up by blowing air and cooling by gas production to form a cycle of producing coal gas (water gas or semi-water gas).

[0069] 1. "Blowing" stage, that is, blowing to heat up, by controlling the amount of oxygen in different concentrations in the air, reducing the time of the blowing stage, wherein the oxygen content in the blowing air is 21% or 22% or 23% or 24% or 25% or 26% or 27% or 28%... etc; blowing percentage corresponds to 22% or 20.7% or 19.6% or 18.5% or 17.5% or 16.6% or 15.8% or 15.0%... etc; one cycle blowing time Corresponding to 33 seconds or 31.1 seconds or 29.37 seconds or 27.78 seconds or 26.32 seconds or 24.97 seconds or 23.72 seconds or 22.56 seconds...etc.

[0070] The purpose of the blowing stage is to use the oxygen in the natural air to blow into the gas-making furnace to oxidize and react with the hot carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com