Optical contraposition apparatus for joint of circuit apparatus and substrates, and system having the same

A circuit device and alignment device technology, applied in optics, printed circuits, nonlinear optics, etc., can solve problems such as the inability to sense the substrate mark X at the same time, reduce the up and down movement of the camera, and the inability to sense at the same time, so as to improve the operation efficiency. , The effect of improving the good rate and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description with accompanying drawings and the preferred embodiments.

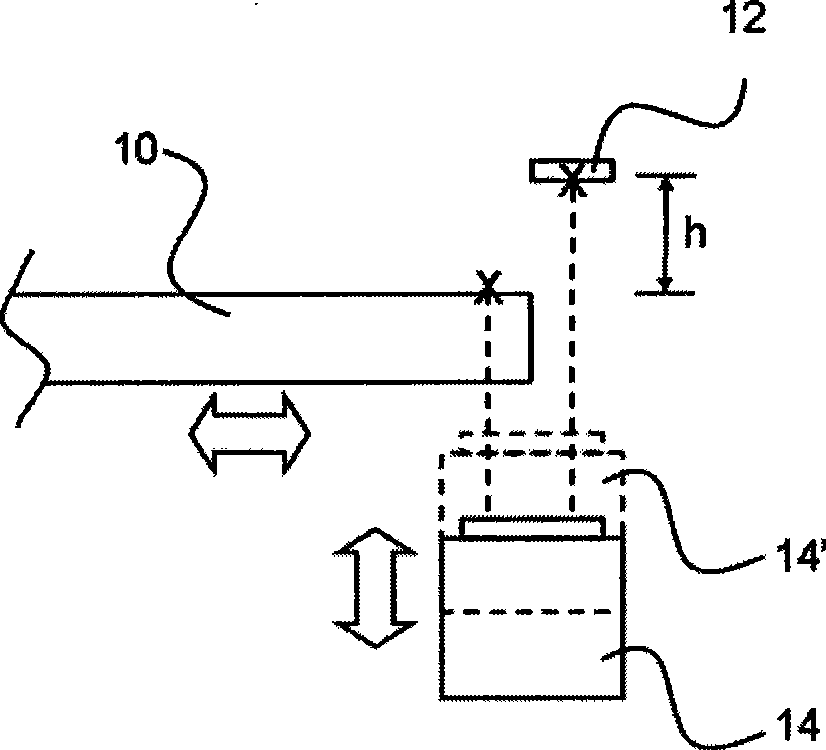

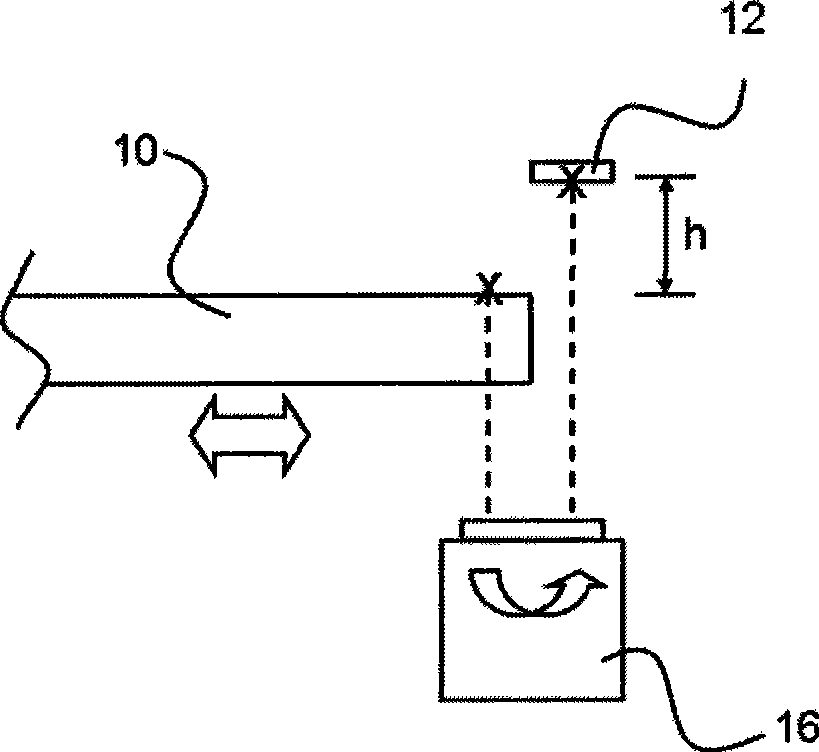

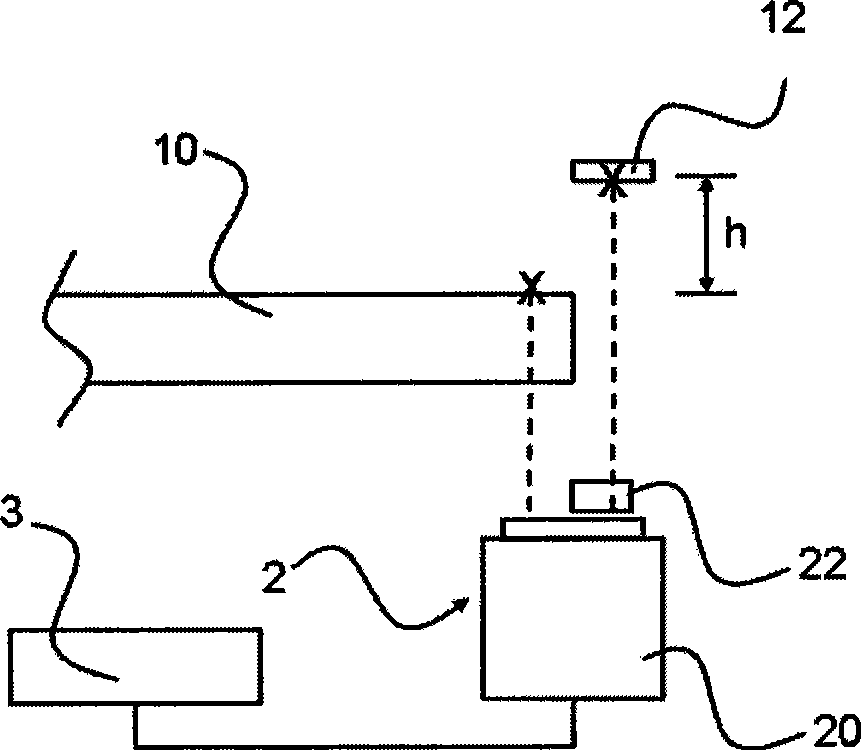

[0034] image 3 It is a schematic diagram of the first preferred embodiment of the application of the present invention. As mentioned above, there is a height difference h between the substrate 10 and the circuit device 12 , and the two need to be precisely aligned and bonded. The optical alignment device 2 of the present invention includes: an optical image capturing unit 20 driven by the control device 3 and synchronously capturing the optical images of the circuit device 12 and the substrate 10 in the height difference direction; . An optical path compensation unit 22 for compensating the optical path difference corresponding to the height difference h between the circuit device 12 and the substrate 10 .

[0035] In order to prevent the circuit device 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com