Electrolytic solution for lithium ionic cell using lithium manganate as positive pole material

A technology for lithium-ion batteries and cathode materials, which is applied in secondary batteries, circuits, electrical components, etc., and can solve the problems of high battery prices and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

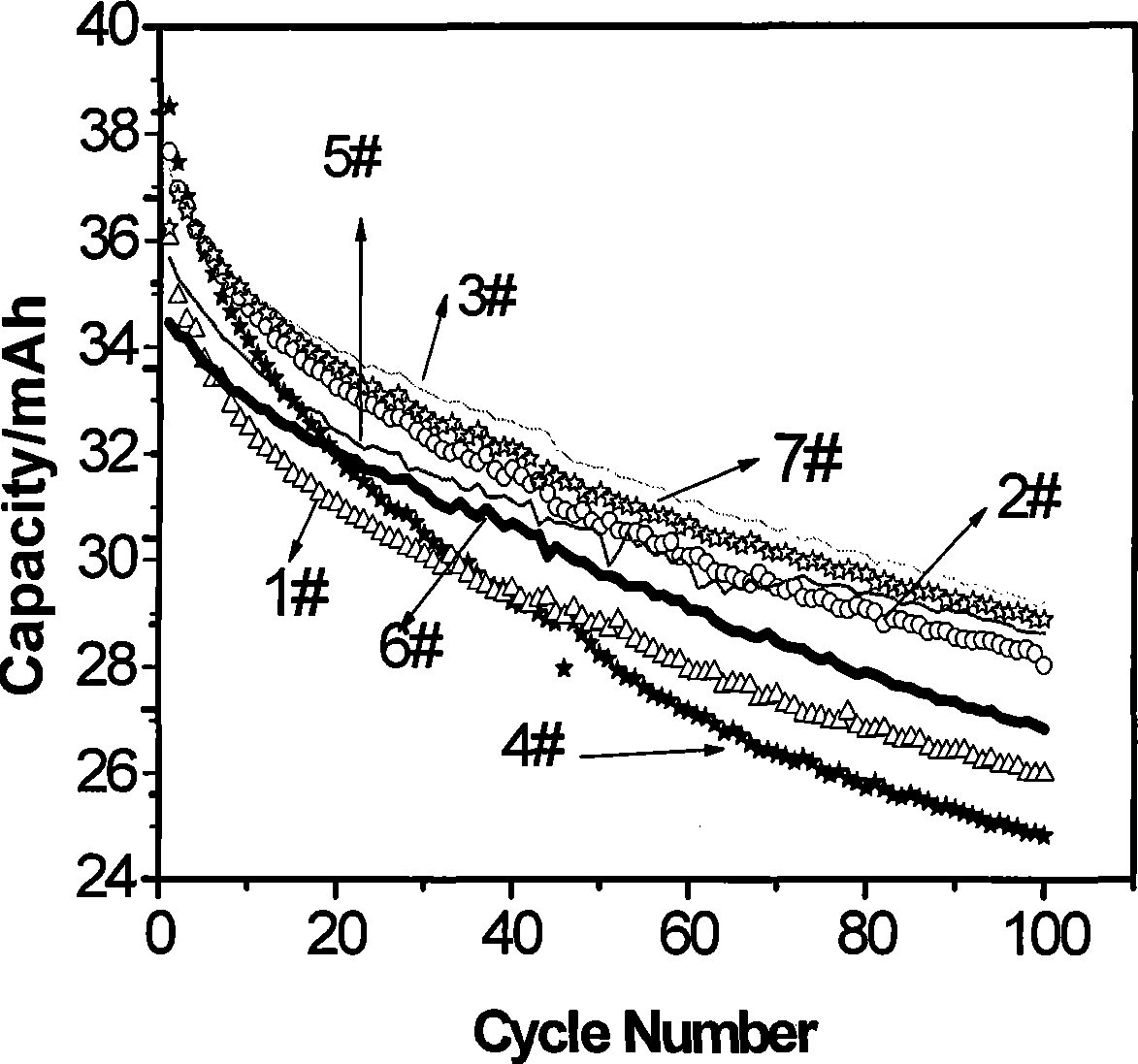

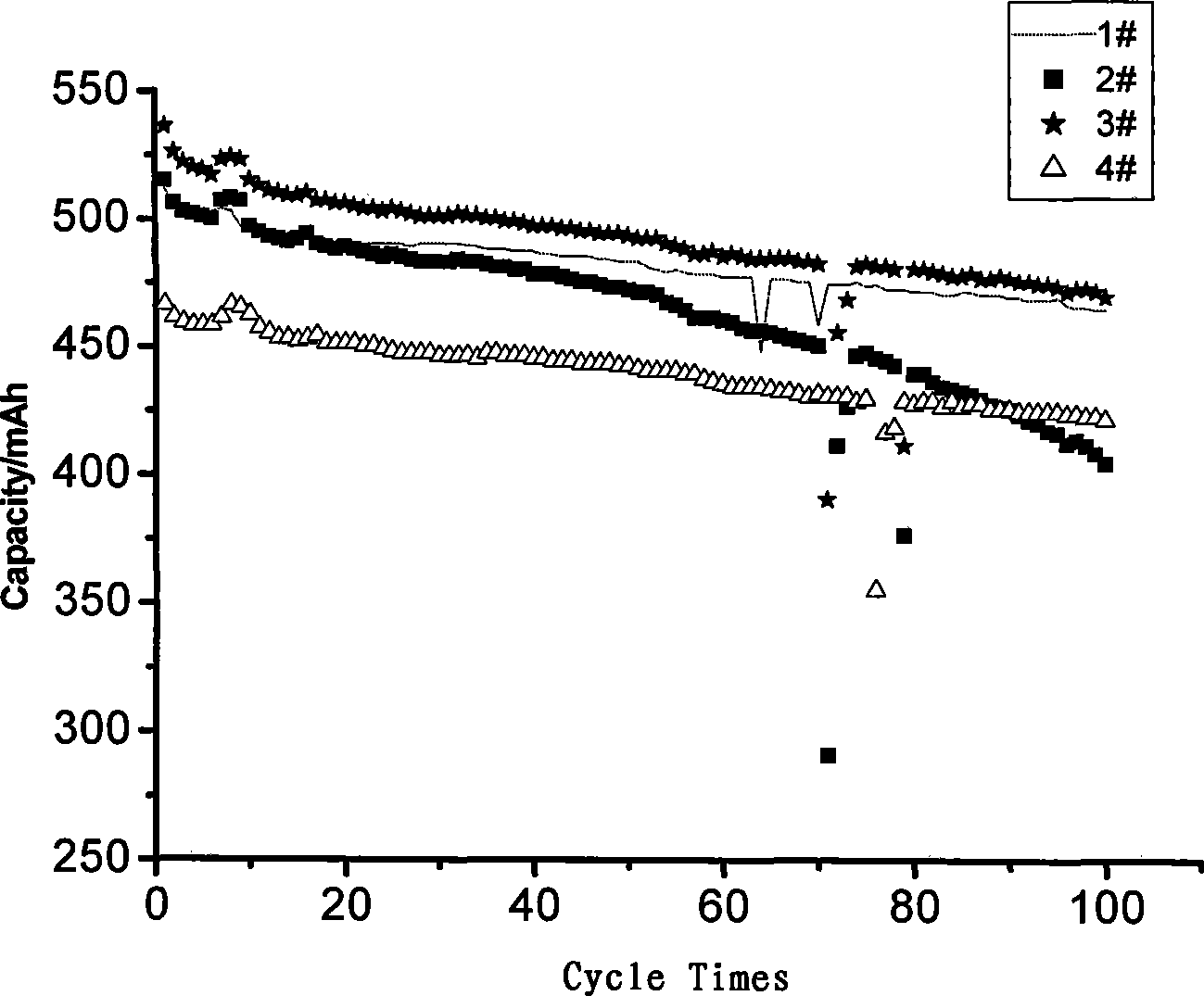

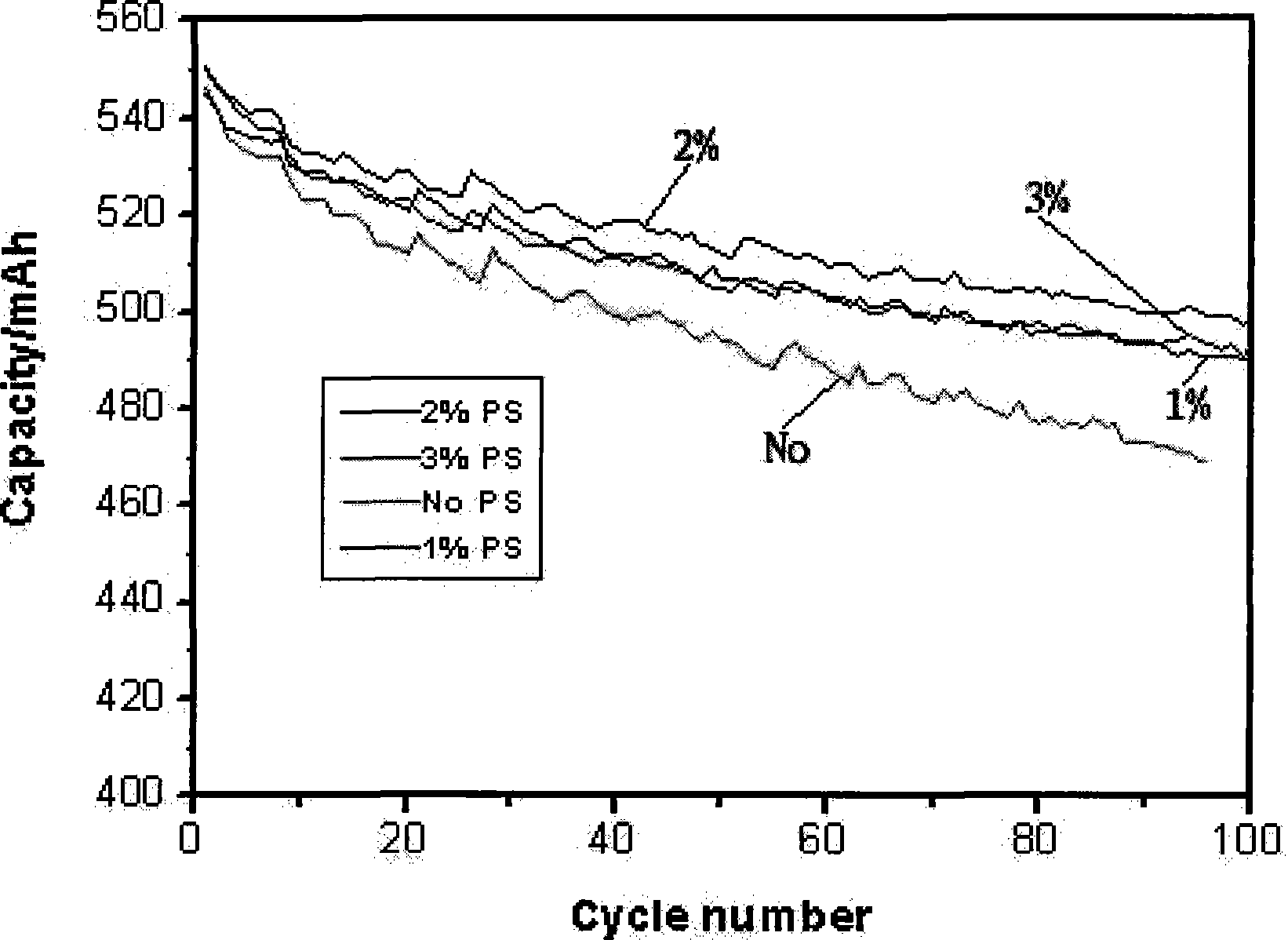

[0029] The present invention starts with the most basic solvent of the electrolyte, finds out a better solvent formula for lithium-ion batteries with lithium manganate as the positive electrode material, and then determines the better lithium salt concentration through experiments, and develops suitable functional additives. The following are respectively explained:

[0030] 1. Development of electrolyte solvent components.

[0031] This part mainly examines the conditions of several commonly used solvent systems. Since EC is an excellent film-forming solvent and an indispensable component in the electrolyte, the solvents we choose are EC (Ethylenecarbonate ethylene carbonate), PC (Propylene carbonate propylene carbonate), DMC (Dimethylcarbonate dimethyl carbonate), EMC (Ethyl methyl carbonate), DEC (Diethyl carbonate diethyl carbonate), MPC (methyl propylene carbonate) And DPC (Dipropylene carbonate dipropyl carbonate). Table 1 is the physical properties of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com