Concrete casting production technique with energy-saving environmental-protection function

A technology for concrete prefabricated parts and production processes, which is applied to manufacturing tools, unloading devices, ceramic molding machines, etc., can solve the problems of inability to isolate vibration and noise, low production efficiency, and excessive steam loss, so as to reduce vibration noise and save energy. Fuel, the effect of promoting promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

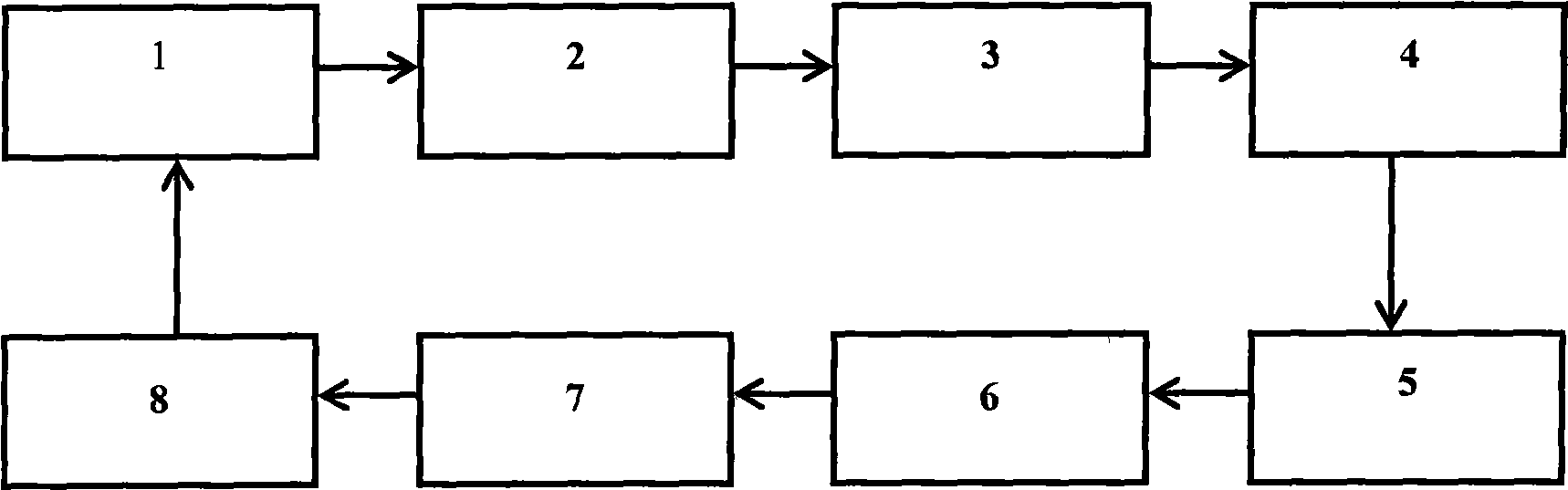

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

[0025] The equipment of the present invention is composed of mold transfer device, concrete pouring equipment, concrete vibrating and sound insulation device, transfer trolley for mold entering and leaving the steam curing room, heat-insulated steam curing room and central control system. The structure and function of each part are as follows:

[0026] The mold transfer device is operated by a chain driven by an oil cylinder or an electric motor. A one-way thrust device is installed on the chain, and the chain moves forward. Each one-way thrust device pushes the corresponding mold forward to the next station of the production line. In order to ensure that there is enough space for soundproofing the vibrating stations and sanitation cleaning after each station is finished, a sufficient length is reserved between each one-way drive on the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com