Self-paralleling front rubber roll apparatus

A front rubber and rubber roller technology, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of uneven fiber pressure, large non-parallelism, increase production costs, etc., to improve yarn quality, The effect of reducing the cost of renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

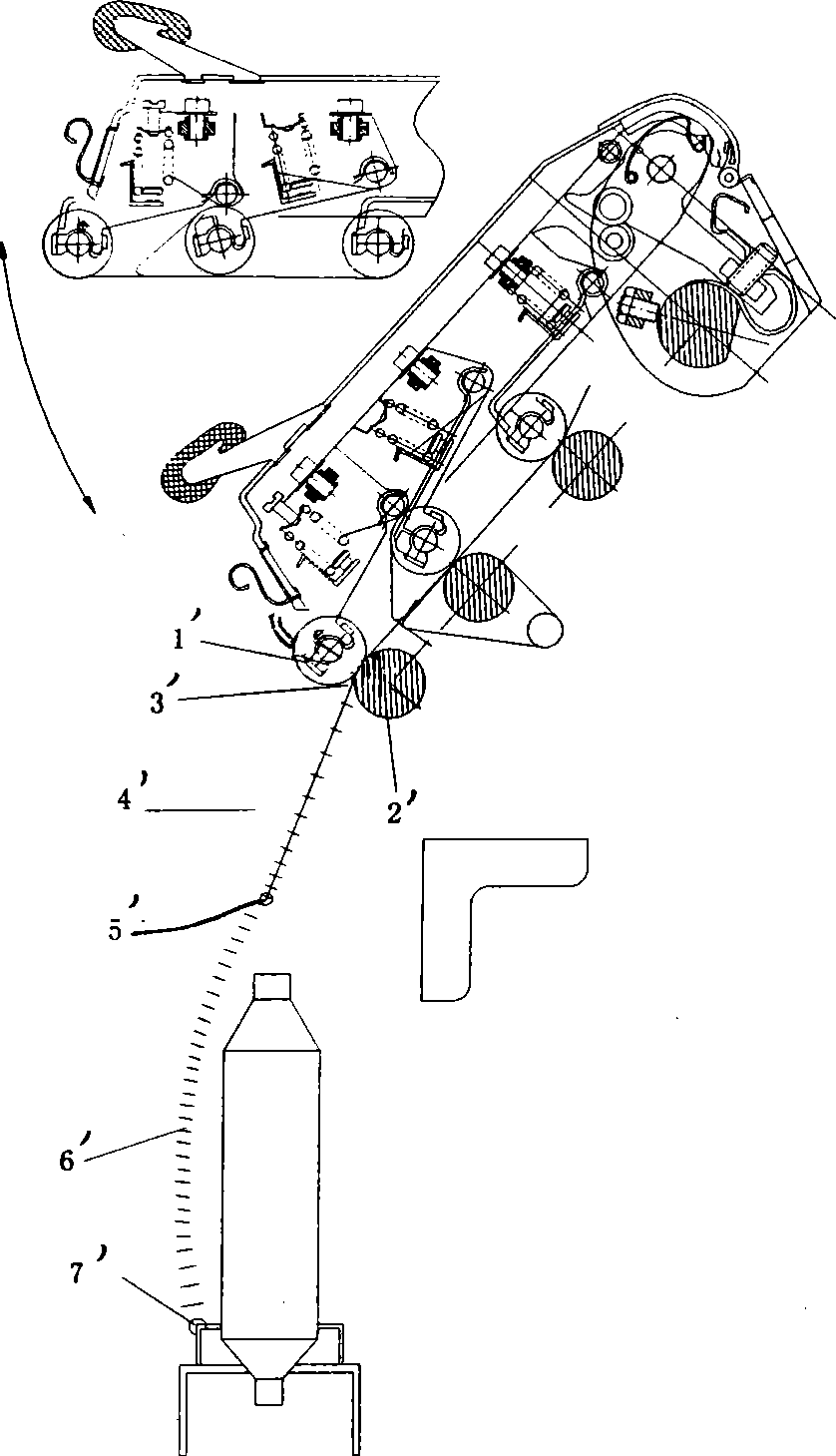

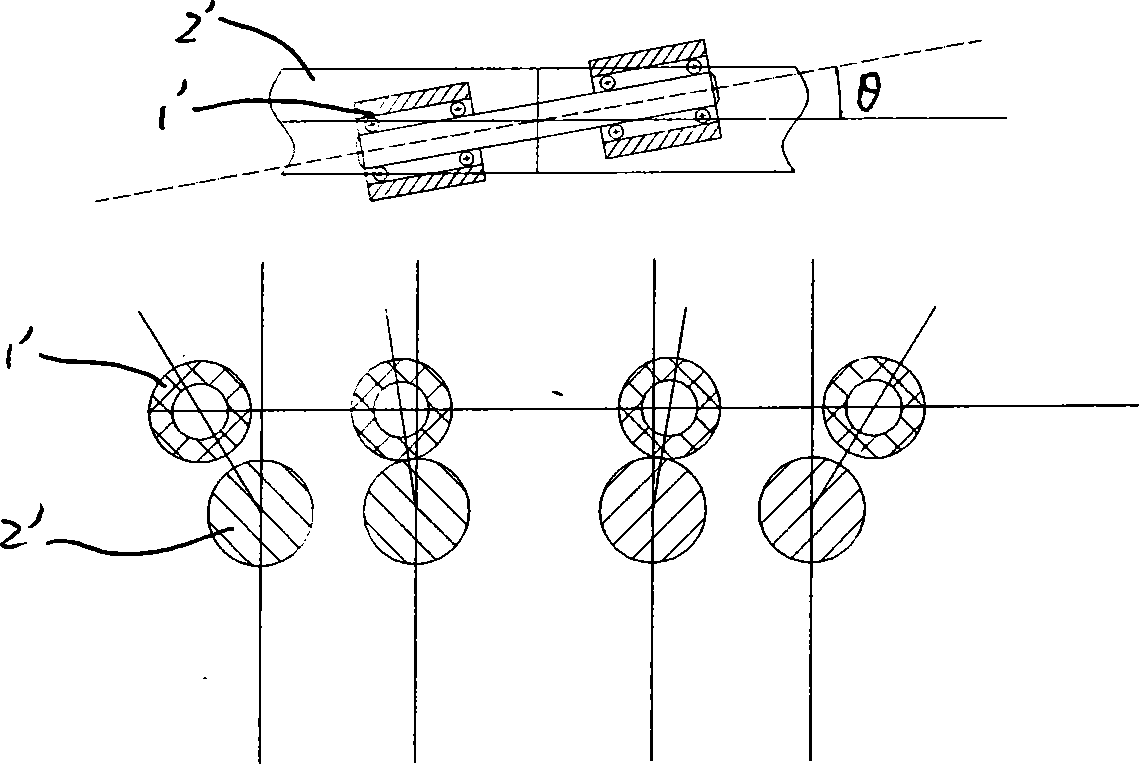

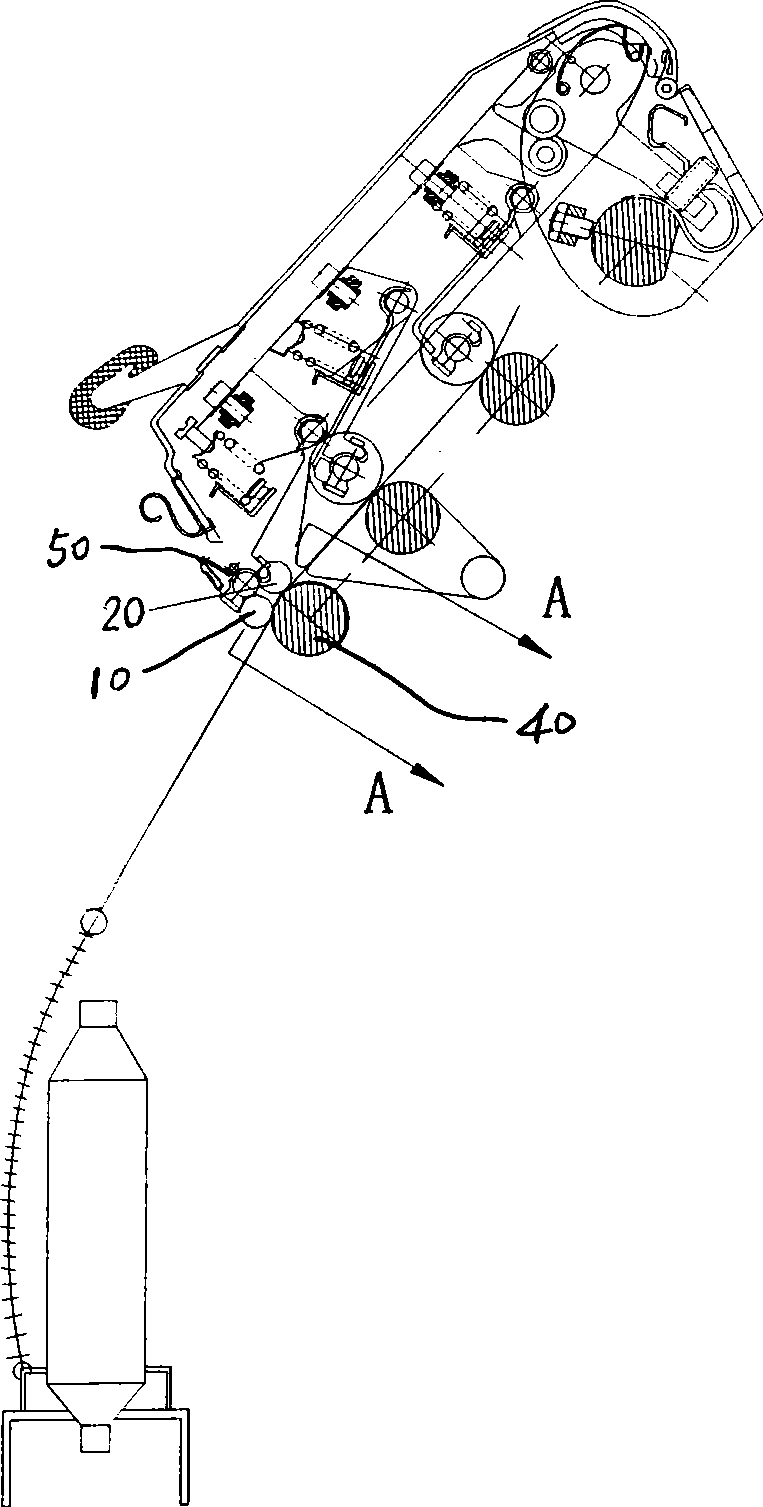

[0028] see image 3 It is the structural representation and the structure diagram of the top spinning machine of the present invention Figure 4 for image 3 As shown in the schematic diagram of the A-A sectional structure of , a self-adjusting parallel front rubber roller device, the front rubber roller 10 is held by the gripper 50 and arranged above the front bottom roller 40 of the ring spinning machine, the front rubber roller 10 and the front bottom roller The roller 40 forms the nip for drafting the roving, wherein the self-adjusting parallel front rubber roller device consists of two groups of front rubber rollers 10, 20 that are axially parallel to each other and are jointly arranged on a pressure seat 30, and the two groups of front rubber rollers The surfaces of the rubber rollers 11, 12 are attached to the surface of the front bottom roller 40 and rotate around the axis respectively, and the gripping claw 50 is held at the pressing seat 30.

[0029] Two arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com