Straightly-connecting explosion suppression swirl vacuum compressor without lubricant

A vacuum compressor, direct-connected technology, applied in the field of vacuum compressors, can solve the problem of difficulty in realizing no leakage of compressed gas, and achieve the effects of small vibration, reduced mechanical loss, and avoidance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

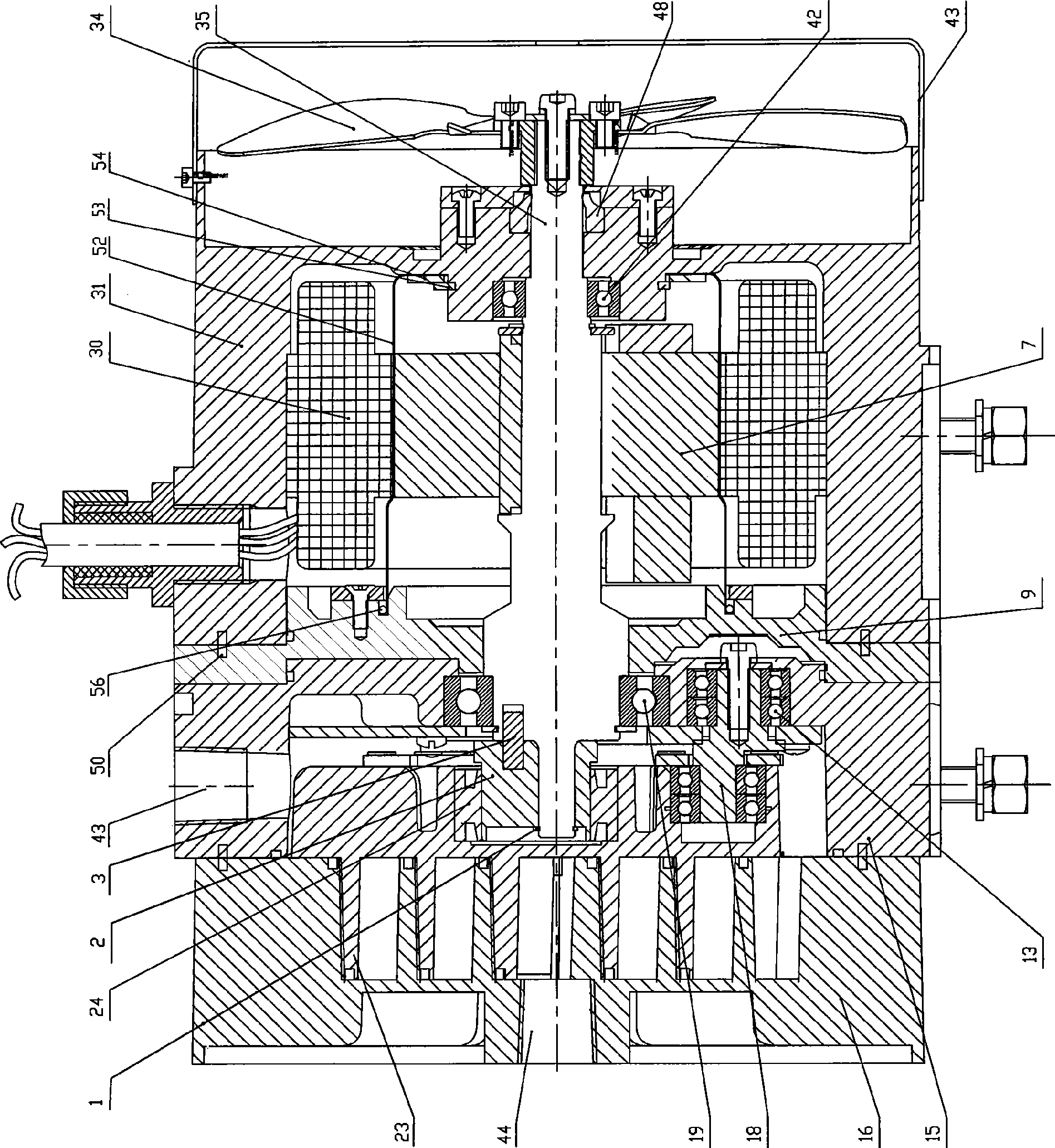

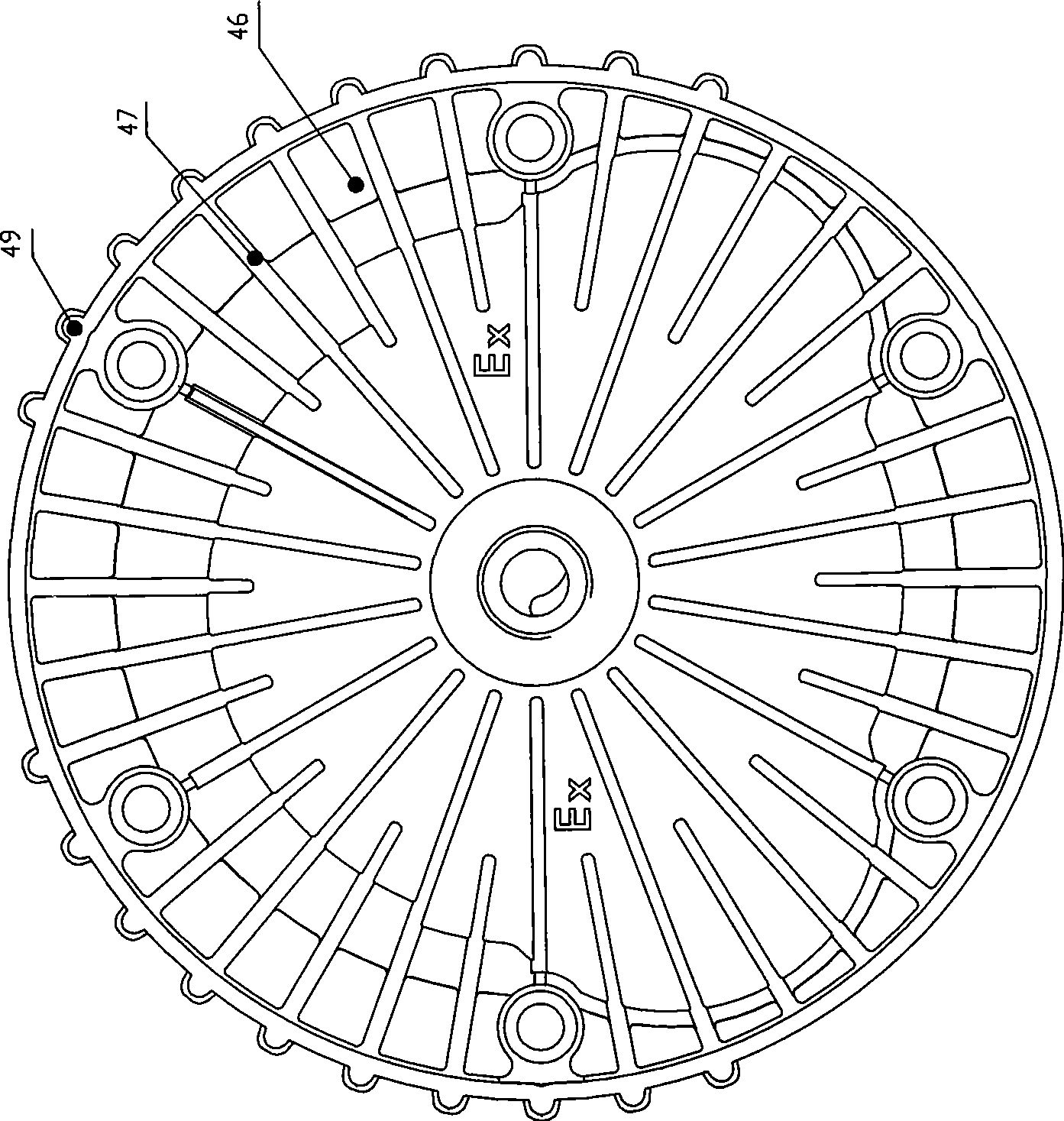

[0024] Example 2, such as Figure 4 As shown, this example is a non-leakage, explosion-proof and oil-free scroll vacuum compressor. The difference between this example and Example 1 is that the main shaft 35 is sealed in the motor casing 31, and the motor casing 31 and the guide A heat dissipation fan 49 with a power source 51 is arranged between the wind shields 43, so that there is no dynamic sealing interface between the inner chamber of the whole machine and the outside to ensure no leakage. This model can be used in special fields such as the compression and transportation of toxic and harmful gases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com