The automatic binding and banknote pressing mechanism is evenly arranged on the two sides of the sorting machine

An automatic tying and sorting machine technology, which is applied in the field of machines for packaging items or materials, can solve the problems of loud noise, large volume, and unstable operation, and achieves the advantages of reduced production cost, compact structure of the whole machine, and reduced failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

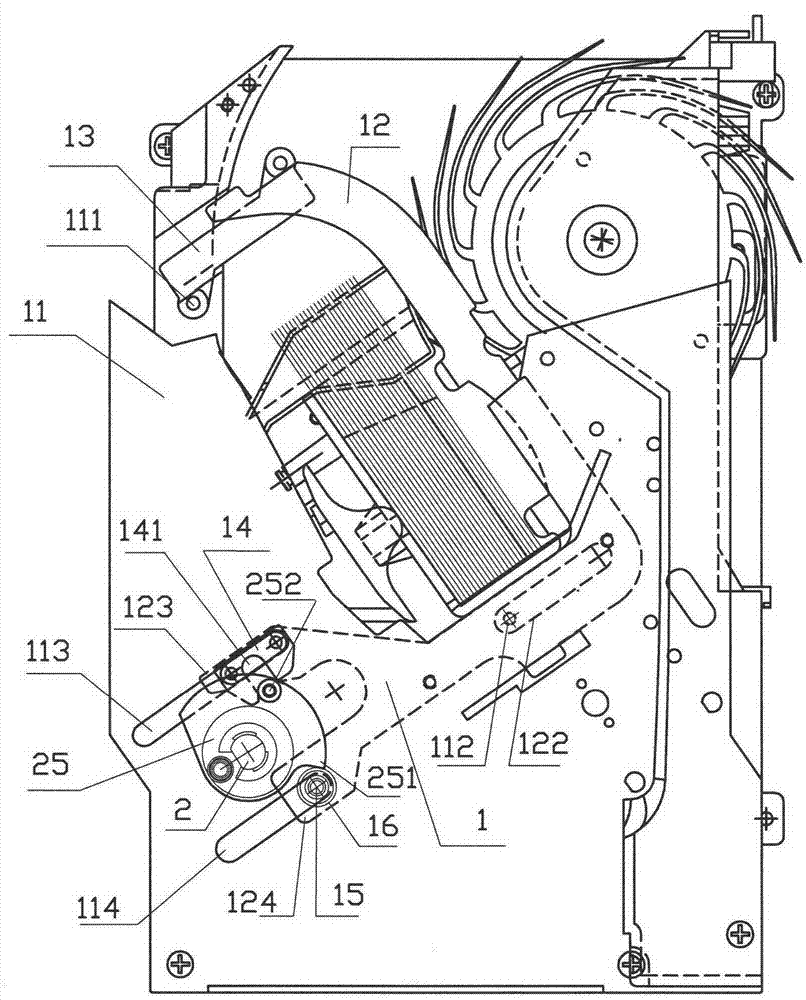

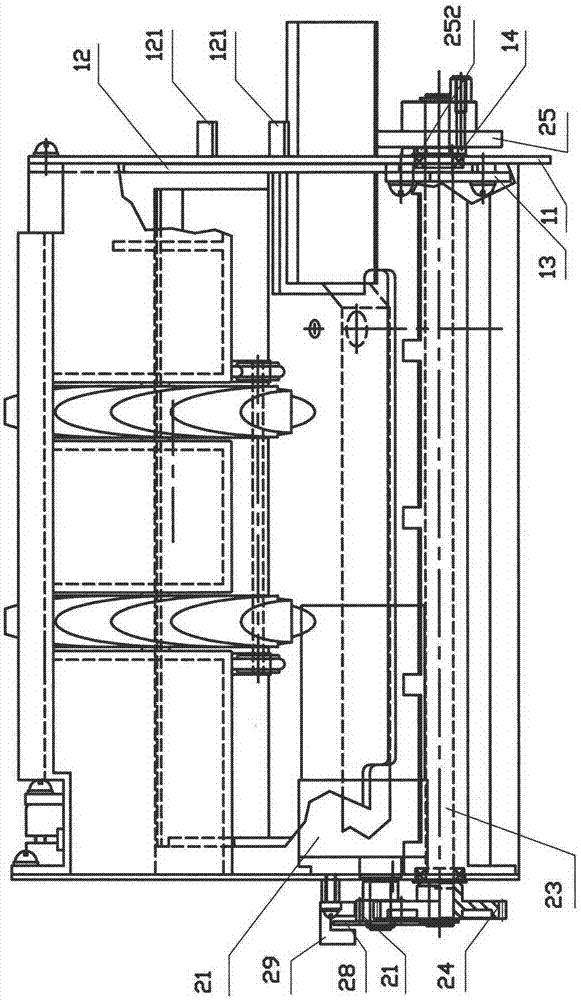

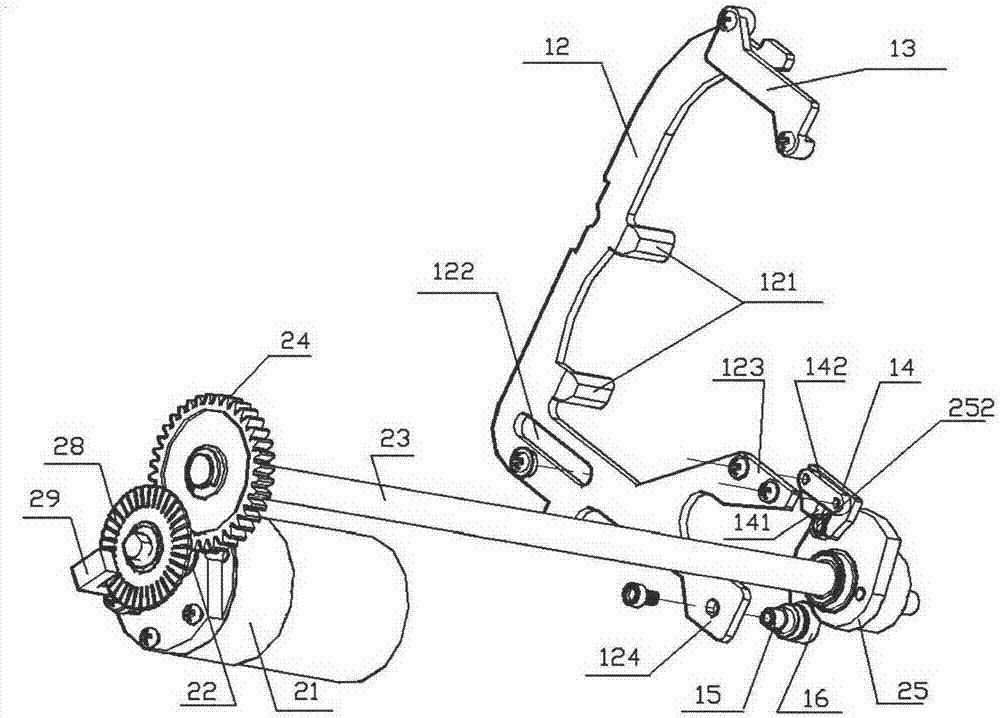

[0012] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0013] Figure 1 ~ Figure 3 It is a structural schematic diagram of an embodiment proposed by the present invention. In the figure, there is an automatic banknote pressing mechanism for a sorting machine, which includes: a banknote pressing assembly 1 and a transmission mechanism 2, wherein:

[0014] Described banknote pressing assembly 1 is made of sorting machine frame side plate 11, banknote pressing slide plate 12, guide plate 13, resetting shift fork 14, pressing banknote semi-axis 15 and roller 16 installed on the semi-axis; It is in reverse C shape, and the C-shaped cavity coincides with the banknote output frame on the side plate of the sorter. The middle and lower parts of the C-shaped cavity are provided with two bending claws 121, and the bottom of the C-shaped cavity extends outwards. The end is fork-shaped, and the root of the C-shaped bottom is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com