Primary gas filling station

A technology for gas filling stations and gas storage cylinders, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, and pressure vessels. To solve problems such as trailer resources, achieve smooth production, save gas storage facilities, and simple and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

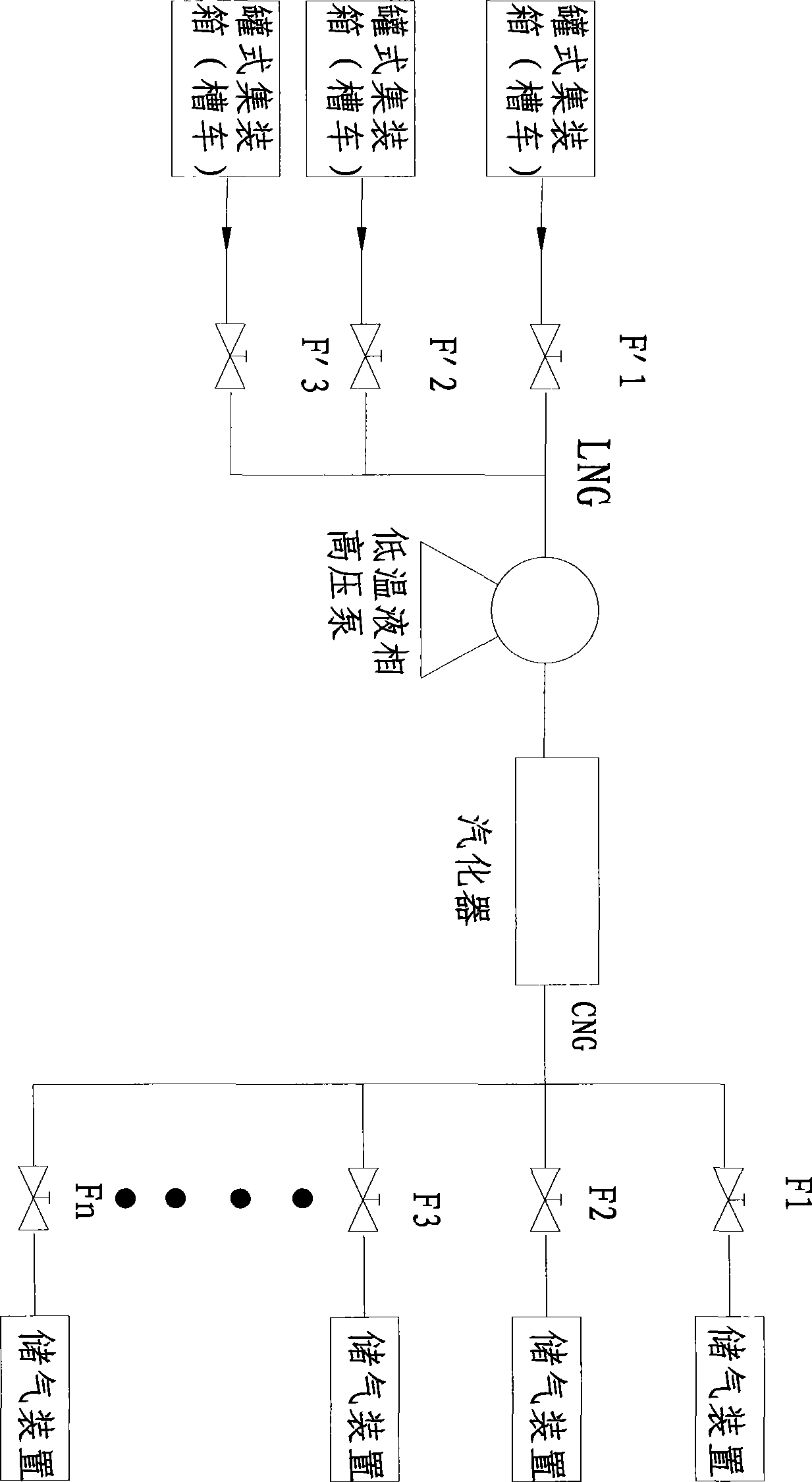

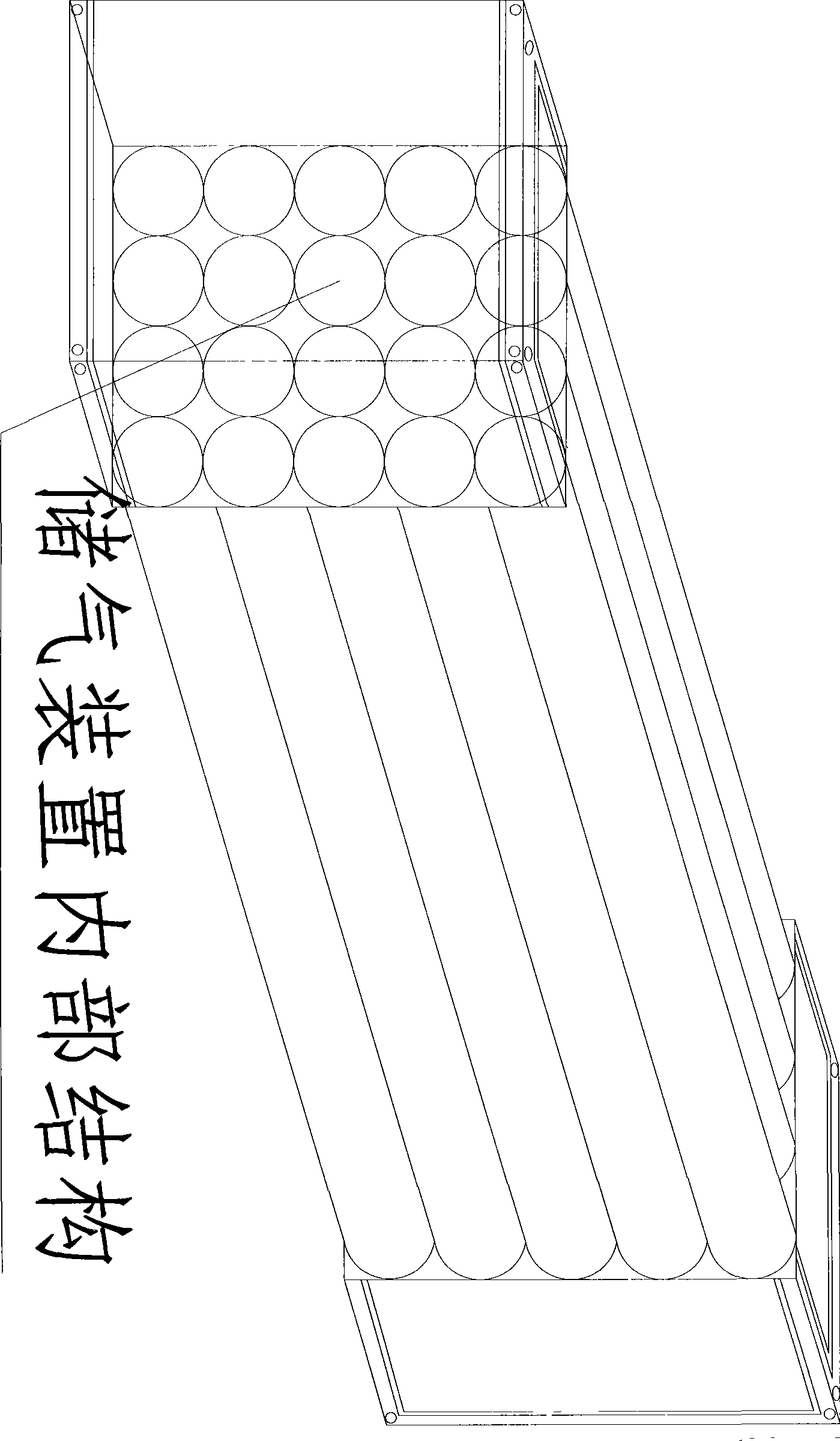

[0043] The parent gas filling station is composed of a low-temperature tank container (tank car), a low-temperature liquid phase high-pressure pump, a vaporizer, and multiple gas storage devices. Its technical characteristics are: multiple gas storage devices, each of which is composed of multiple It is composed of a 25MPa high-pressure CNG compressed natural gas storage cylinder, and its gas storage device is made into a multi-tube bundle container, a container analog or a multi-long tube trailer.

[0044] The gas storage device is used as a common gas storage device exchanged between the parent and child stations.

[0045] according to figure 1 Process flow:

[0046] Three low-temperature tank containers (tank trucks) are parked and connected to the low-temperature liquid-phase high-pressure pump through valves F′1, F′2, and F′3 respectively. After the LNG of the tank container (tank truck) is used up, close the F′1 valve, open the F′2 valve, use the LNG of the second low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap