Thermoelectric facility comprising a thermoelectric generator and means for limiting the temperature on the generator

A technology of thermoelectric devices and generators, applied to engine components, machines/engines, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve problems such as limiting the temperature of generators, and achieve the effect of buffering temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

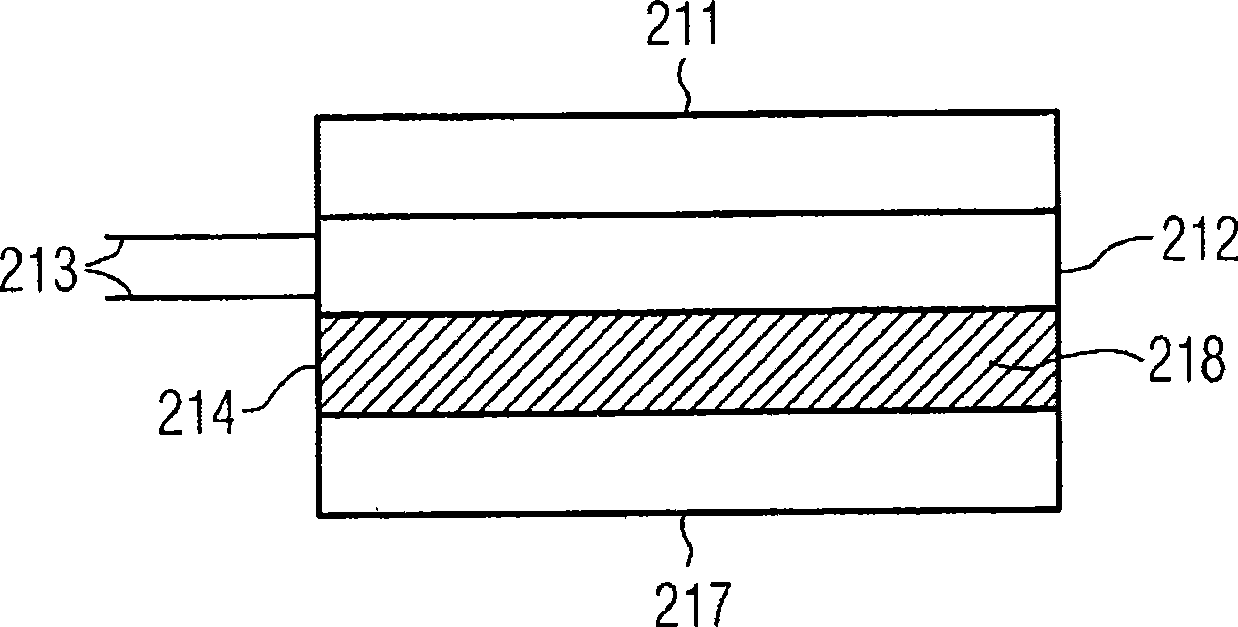

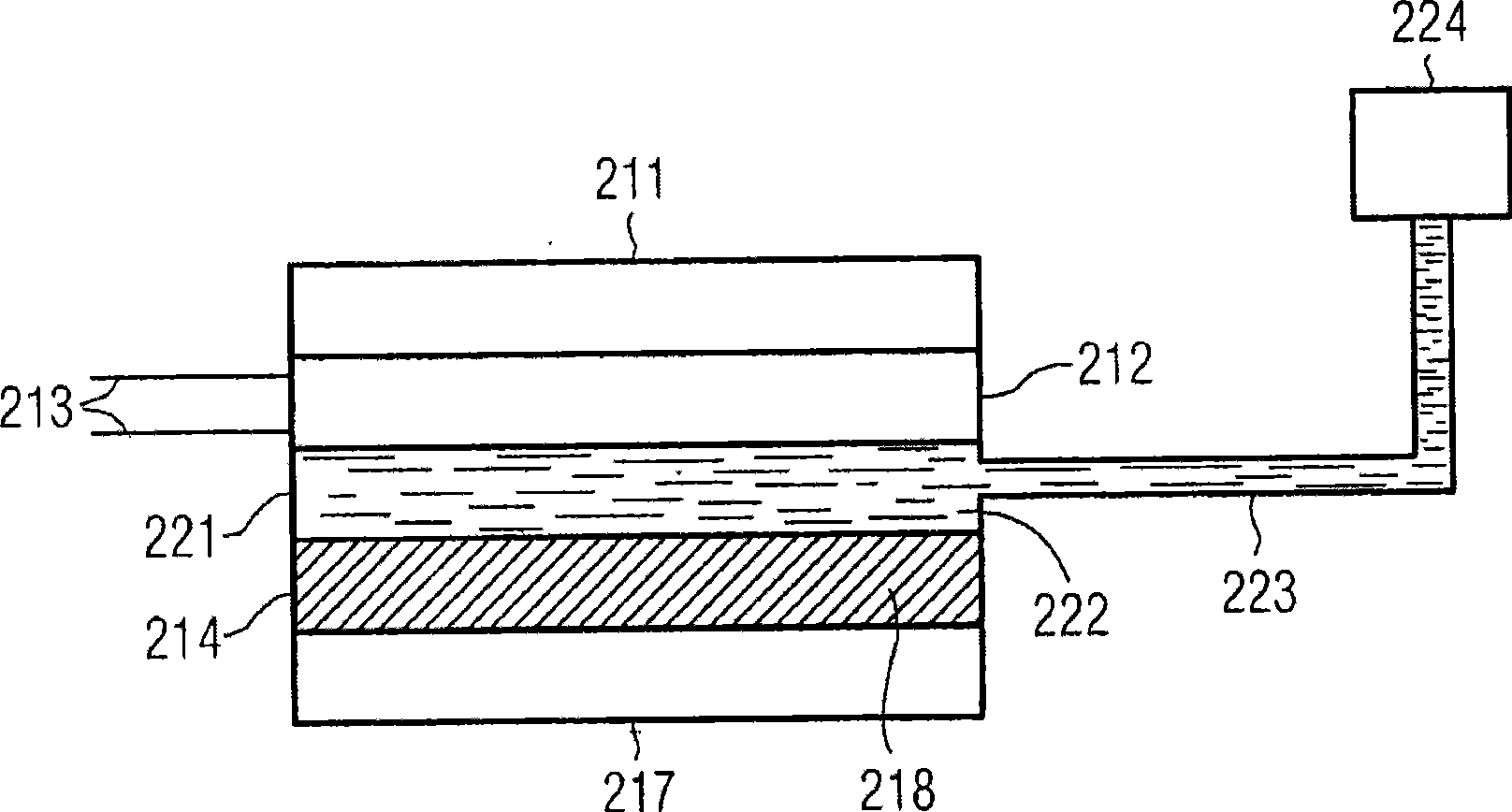

[0040] figure 1 The schematic representation shows the structure of the thermoelectric device according to the preferred embodiment. Its thermoelectric generator 212 is thermally connected to the cold source 211 on the first side over a large area. The hot side of the thermoelectric generator 212 is thermally connected to the cavity 214 filled with the meltable first working medium 218 in a large area. The first cavity 214 is thermally connected to the heat source 217 over a large area. The thermal connection between the above-mentioned elements can preferably be realized by a mechanical connection of the same large area.

[0041] The heat source 217 and the cold source 211 cause a temperature gradient to be formed on the thermoelectric generator 212. The voltage can be intercepted on the electrical connector 213 of the thermoelectric generator 212.

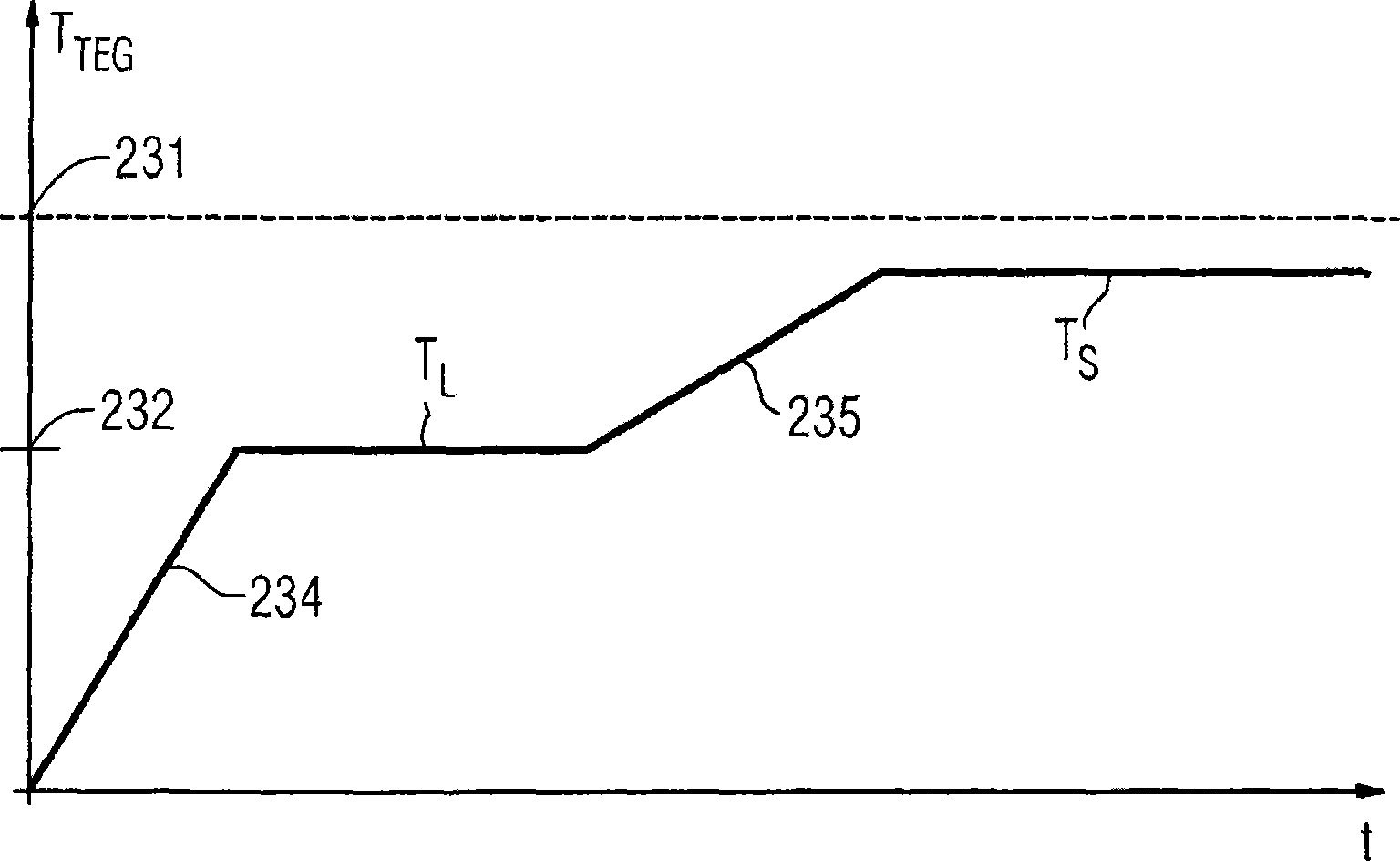

[0042] To illustrate, press figure 1 The operating mode of the thermoelectric device of the preferred embodiment shown can be ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com