Improved copper ethylene absorbent and preparation method thereof

A technology of copper ethylene and absorbent, which is applied in the field of modified copper ethylene absorbent and its preparation, which can solve the problems that the absorbent cannot be recycled and reused, food safety problems, environmental pollution, etc., and the recovery method is simple and easy, and the distribution is uniform , good fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

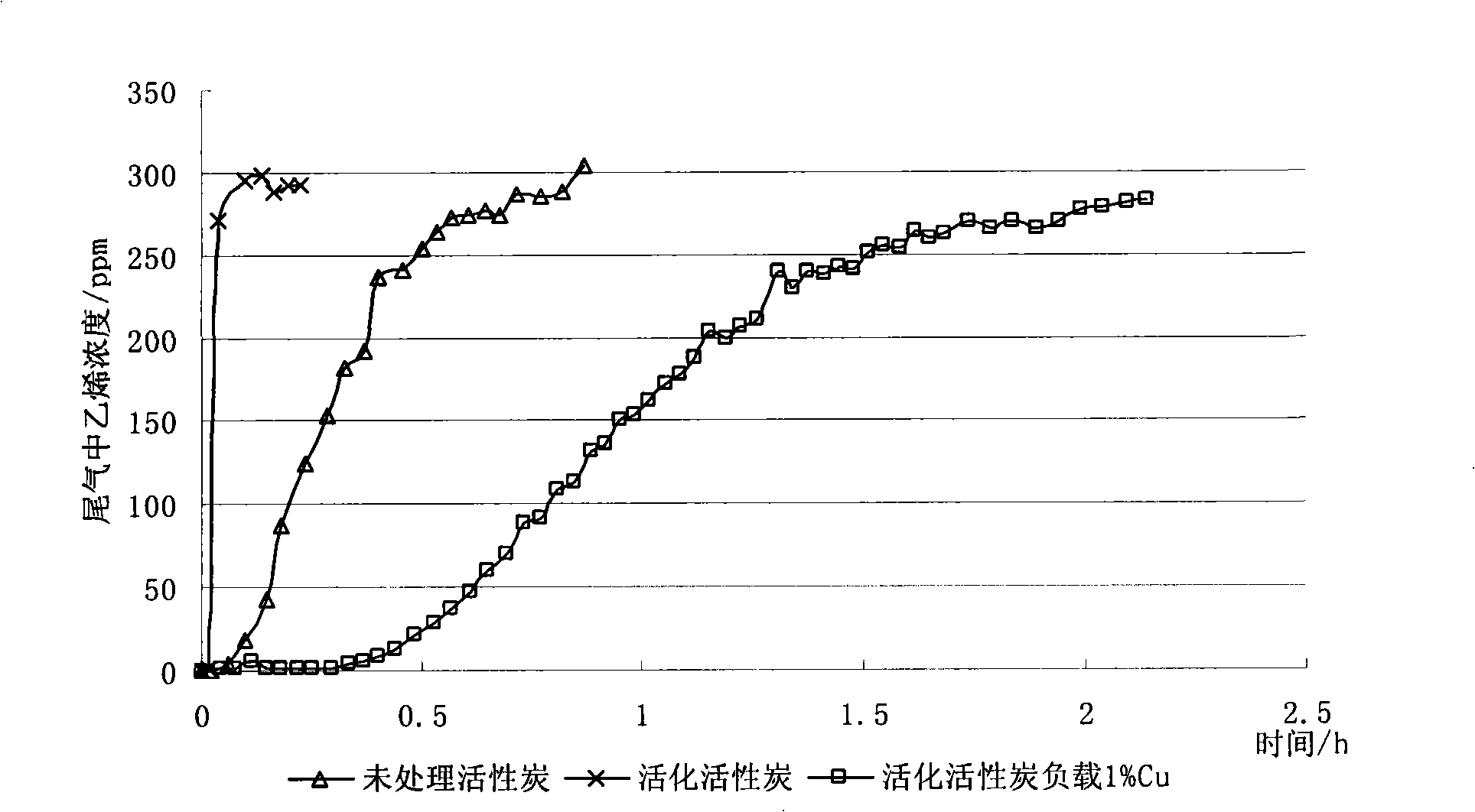

[0039] (1) Using equal volume impregnation method, 0.1336gCuCl 2 2H 2 O was dissolved in 7.5ml deionized water to prepare an impregnating solution, and then 5 g of activated activated carbon was immersed in the impregnating solution for 6 hours to obtain a sample;

[0040](2) The sample obtained in step (1) was dried in an oven at 100°C for 4 hours, then transferred to a muffle furnace and roasted at 400°C for 1 hour in a nitrogen atmosphere, and then placed in a 400°C, hydrogen flow rate of 40ml / min Reducing in a reducing tube for 2 hours, the modified copper ethylene absorbent is obtained, wherein the weight percentage of Cu is 1%, and the weight percentage of activated carbon is 99%.

[0041] The absorption penetration ability of this absorbent to ethylene is shown in figure 1 , the test method is: at room temperature and normal pressure, air with an ethylene concentration of 300ppm is passed into the same amount of modified copper ethylene absorbent, untreated activated ...

Embodiment 2

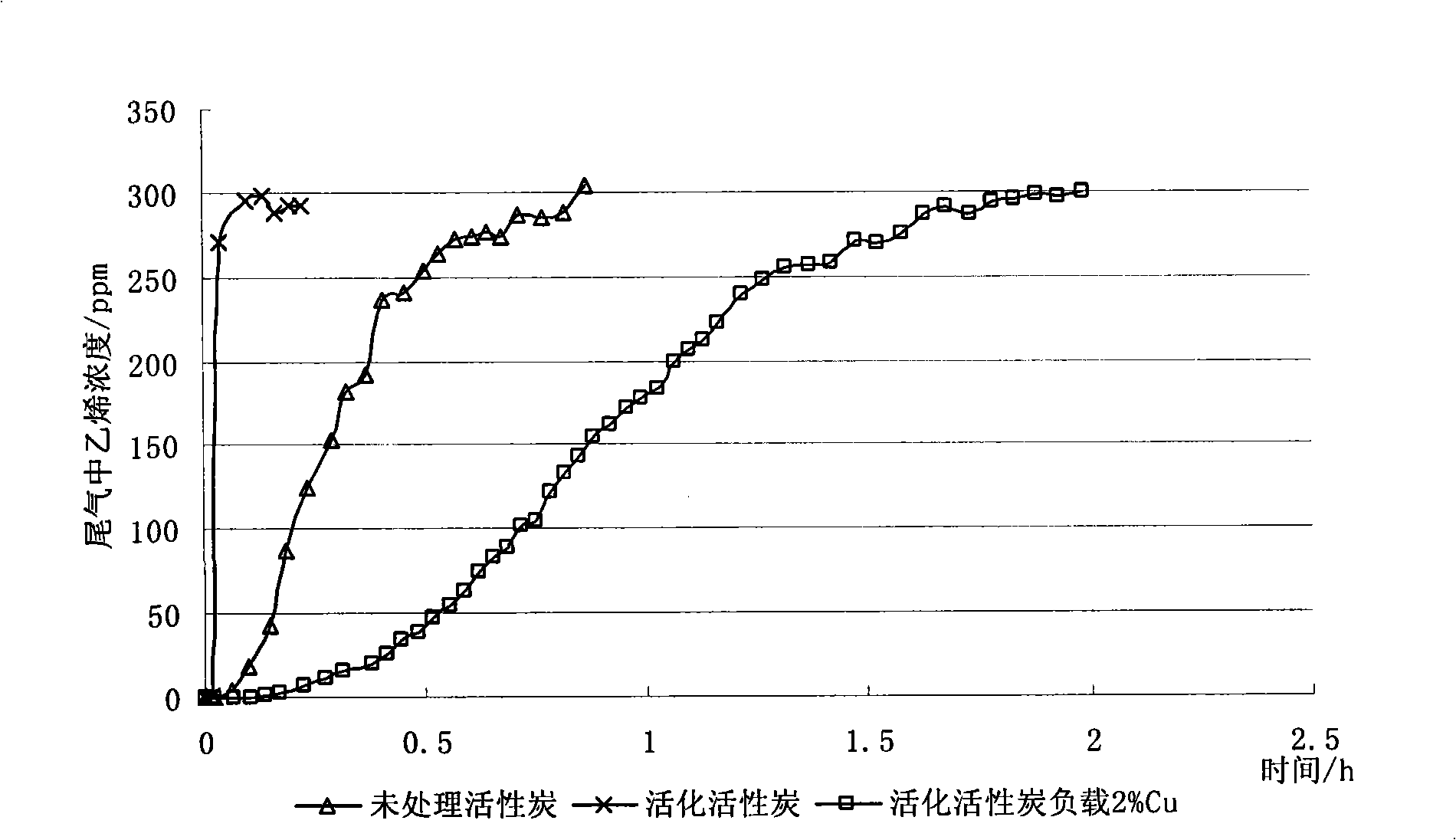

[0044] (1) Using equal volume impregnation method, 0.2671gCuCl 2 2H 2 O was dissolved in 7.5ml deionized water to prepare an impregnating liquid, and then 5 g of activated activated carbon was immersed in the impregnating liquid for 5 hours to obtain a sample;

[0045] (2) The sample obtained in step (1) was dried in an oven at 100°C for 4 hours, then transferred to a muffle furnace and roasted at 400°C for 1 hour in a nitrogen atmosphere, and then placed in a 400°C, hydrogen flow rate of 40ml / min Reducing in a reducing tube for 2 hours, the modified copper ethylene absorbent is obtained, wherein the weight percentage of Cu is 2%, and the weight percentage of activated carbon is 98%.

[0046] The absorption penetration ability of this absorbent to ethylene is shown in figure 2 , test method with embodiment 1.

Embodiment 3

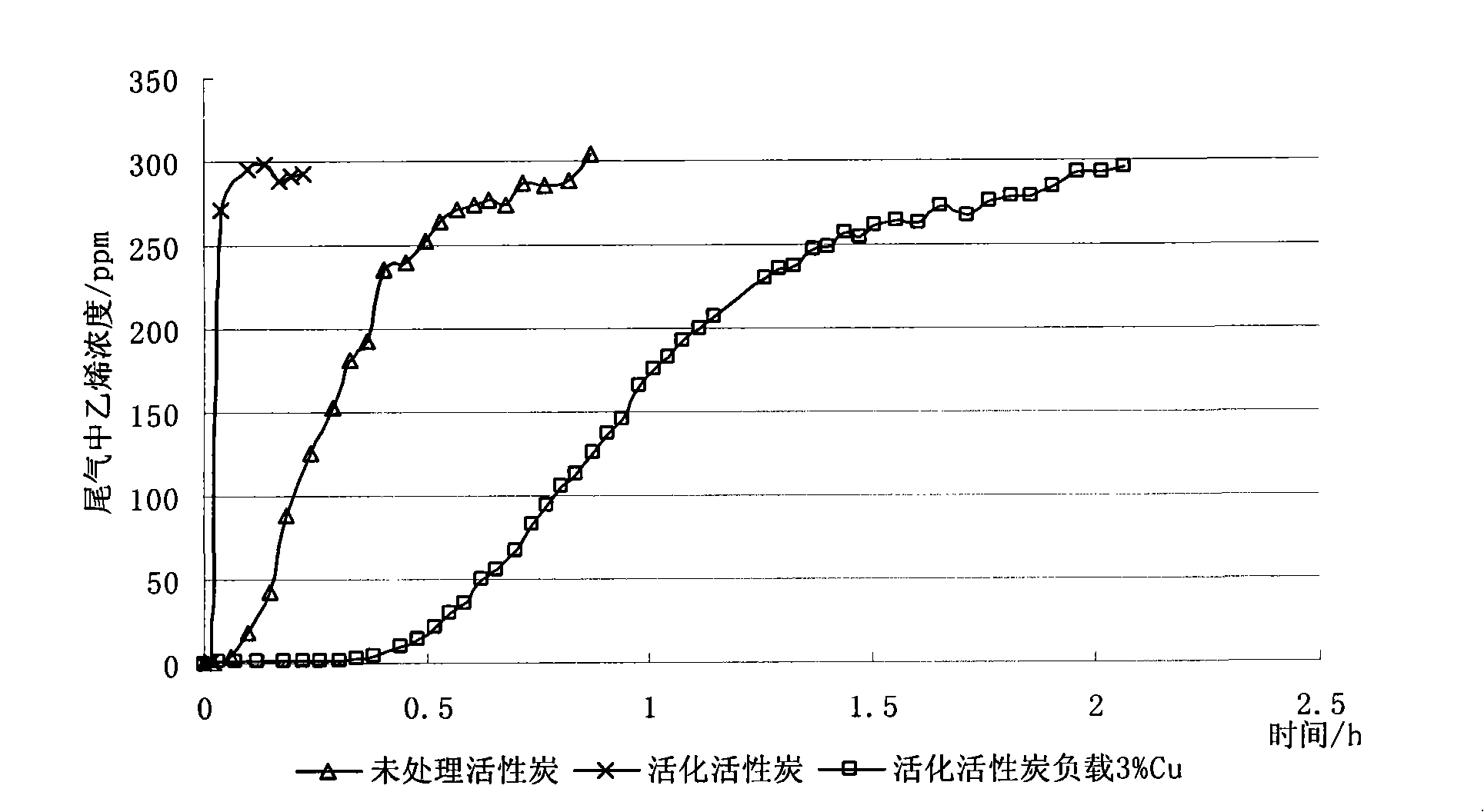

[0048] (1) Using equal volume impregnation method, 0.4008gCuCl 2 2H 2 O was dissolved in 7.5ml deionized water to prepare an impregnating liquid, and then 5 g of activated activated carbon was immersed in the impregnating liquid for 5 hours to obtain a sample;

[0049] (2) The sample obtained in step (1) was dried in an oven at 100°C for 4 hours, then transferred to a muffle furnace and roasted at 400°C for 1 hour in a nitrogen atmosphere, and then placed in a 400°C, hydrogen flow rate of 40ml / min Reducing in a reducing tube for 2 hours, the modified copper ethylene absorbent is obtained, wherein the weight percentage of Cu is 3%, and the weight percentage of activated carbon is 97%.

[0050] The absorption penetration ability of this absorbent to ethylene is shown in image 3 , test method with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com