Phenol ortho-methylation catalyst and preparation method thereof

A catalyst and methylation technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of unfavorable environmental protection, high reaction temperature, and low selectivity of o-cresol, etc. High stability, low reaction temperature, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh Fe(NO 3 ) 3 9H 2 O 404g and Mg(NO 3 ) 2 ·6H 2 O 51.2g was mixed and dissolved in 800mL ethanol, and then it was slowly mixed with 700mL of 28% concentrated ammonia water containing 4g PEG in parallel flow under ultrasonic conditions at room temperature. Wash and dry at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10-20 meshes, which is the obtained catalyst Fe. 1 Mg 0.2 / o.

[0021] The above-mentioned catalyst is packed in a stainless steel tube with an inner diameter of Φ7mm, the packing mass is 8g, the reaction temperature is 310°C, the raw material is phenol:methanol:water=1:4:3 (both are molar ratios), and the feed space velocity is 1.0 h -1 , the carrier gas is N 2 The flow rate was 25mL / min, the reaction was 24h, the conversion rate of phenol was 47.3%, the selectivity of o-cresol was 90.2%, and the selectivity of 2,6-xylenol was 9.7...

Embodiment 2

[0023] Weigh anhydrous Fe(OAc) 3 233g and Mg(OAc) 2 Mix and dissolve 284g in 800mL ethanol, then slowly mix it with 1000mL of 28% concentrated ammonia water containing 8g PEG in parallel flow under the condition of ultrasonic at room temperature, continue to ultrasonicate for 30min after adding, then filter the precipitate, wash, Bake at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and after being pressed into tablets, it is crushed into small particles of 10-20 meshes, which is the catalyst Fe obtained. 1 Mg 2 / o.

[0024] The prepared catalyst was filled in a stainless steel tube with an inner diameter of Φ7mm, the filling mass was 8g, the reaction temperature was 350°C, the raw material was phenol:methanol:water=1:4:3 (both in molar ratio), and the feed space velocity was 1.0h -1 , the carrier gas is N 2 The flow rate was 25mL / min, the reaction was 24h, the conversion rate of phenol was 48.6%, ...

Embodiment 3

[0026] Weigh Fe(NO 3 ) 3 9H 2 O 404g, Mg(NO 3 ) 2 ·6H 2 O 25.6g and Ce(NO 3 ) 3 ·6H 2 O2.17g was mixed and dissolved in 800mL ethanol, and then it was slowly mixed with 28% 700mL concentrated ammonia water containing 0.8g PEG in a parallel flow under ultrasonic conditions at room temperature. , washed, and baked at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10-20 meshes, which is the obtained catalyst Fe. 1 Mg 0.1 Ce 0.01 / o.

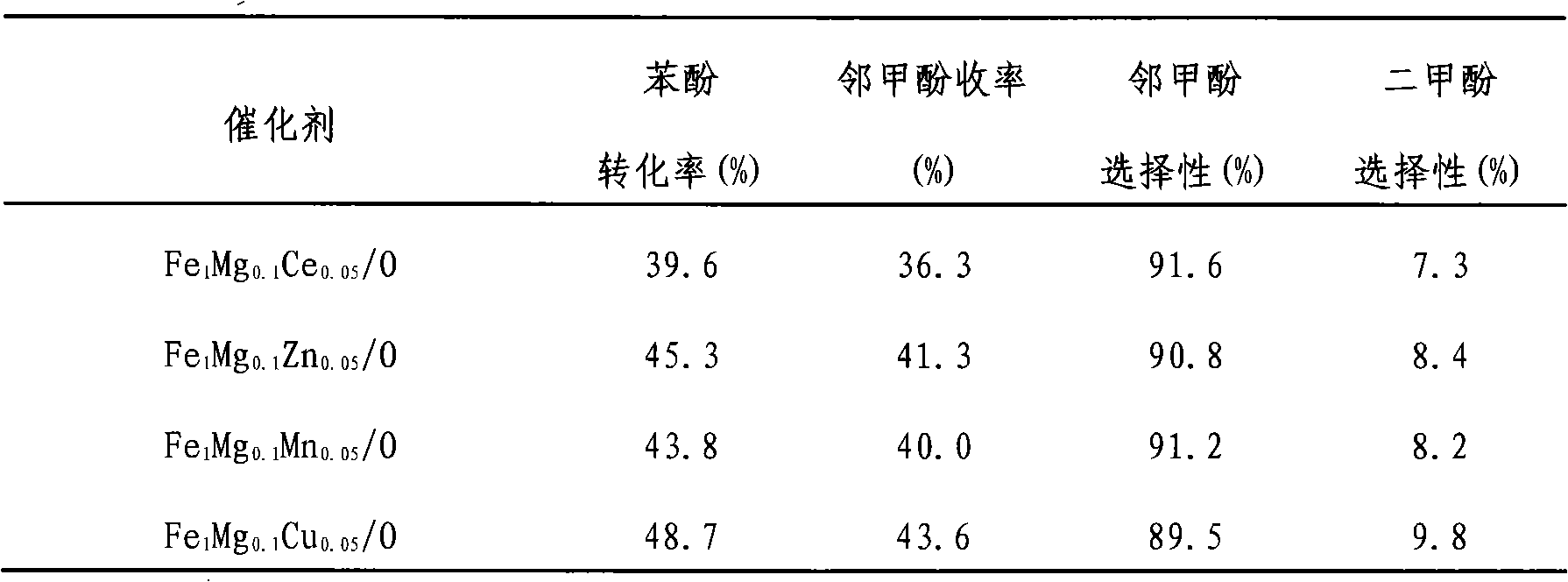

[0027] The catalyst loading method and reaction conditions are the same as in Example 1, and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com