Method for recycling textile, printing and dyeing wastewater

A treatment method and technology for printing and dyeing wastewater, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of saving water resources and using good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

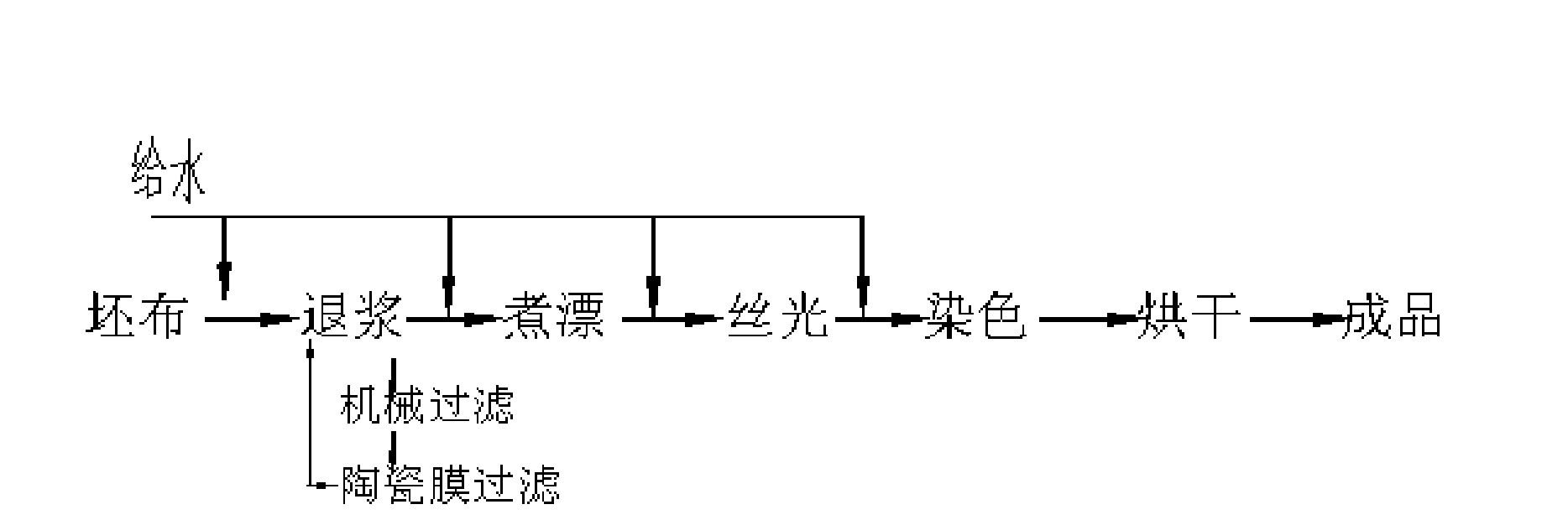

[0013] Example 1. Reuse treatment of desizing wastewater. Such as figure 1 As shown, the desizing wastewater generated in the desizing section is first filtered through a mechanical filter to remove suspended solids and colloids in the wastewater, and then filtered through a ceramic membrane module to retain most of the pollutants in the wastewater, and then filtered The water is directly reused in the desizing section as desizing water. This process has carried out a large number of experiments on the ceramic membrane module. According to the pore size of the ceramic membrane is 50nm, the mechanical filtration+ceramic membrane filtration treatment method of the present invention can reach the following technical indicators, see Table 1.

[0014] Table 1 Technical indicators of desizing wastewater reuse

[0015] project

CODcr (mg / L)

Removal rate

Chroma (times)

Removal rate

temperature

Desizing wastewater

17500

32

8...

Embodiment 2

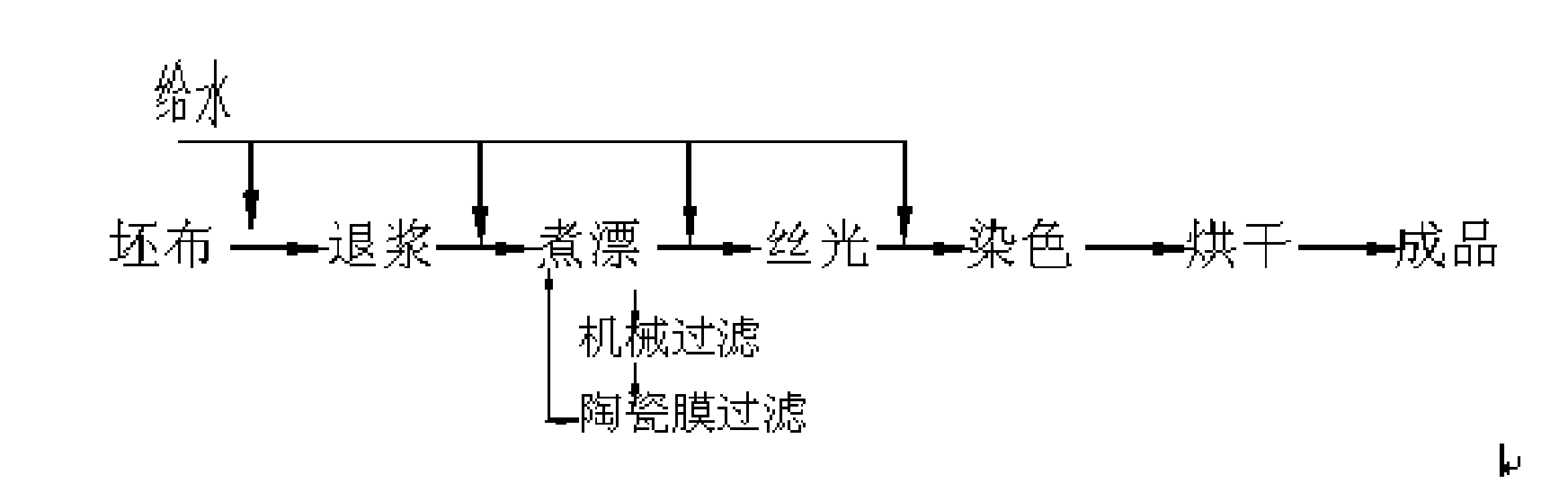

[0019] Example 2. Reuse of bleaching wastewater. Such as figure 2 As shown, the bleaching wastewater produced in the boiling and bleaching section is first filtered through a mechanical filter to remove suspended solids and colloids in the wastewater, and then filtered through a ceramic membrane module to retain most of the pollutants in the wastewater, and then filtered. The water is reused in the scouring and bleaching section as scouring water. The mechanical filter adopts a steel filter element, the filter element adopts a stainless steel wire-wound tube, and the filtration accuracy is 0.1mm. The mechanical filter uses a high-pressure pump to feed water, with a head of 80 meters, and automatically backwashes through the pressure difference between the inlet and outlet, and the pressure difference is set at 0.5kgf / cm 2 . The ceramic membrane module adopts the ceramic ultrafiltration membrane produced by Nanjing Jiusi Hi-Tech Co., Ltd., with a pore size of 50nm, and the...

Embodiment 3

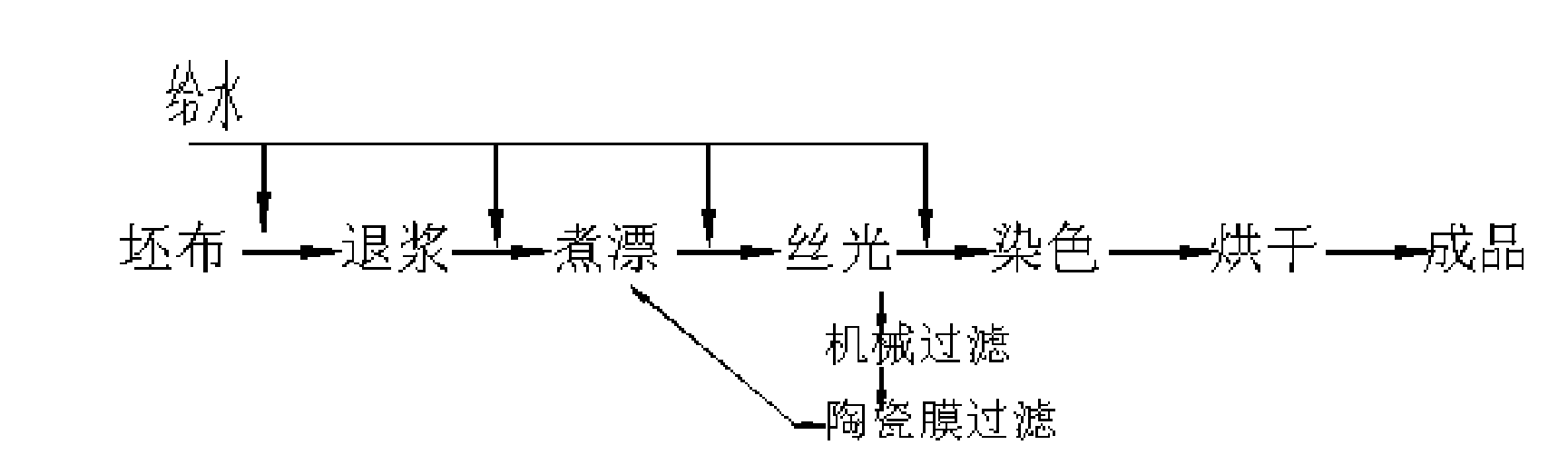

[0023] Example 3. Reuse treatment of mercerizing wastewater. Such as image 3 As shown, the mercerizing wastewater produced in the mercerizing section is first filtered through a mechanical filter to remove suspended solids and colloids in the wastewater, and then filtered through a ceramic membrane module to retain most of the pollutants in the wastewater, and then the filtered water It is reused in the cooking and bleaching section as water for boiling and bleaching. The mechanical filter adopts a steel filter element, the filter element adopts a stainless steel wire-wound tube, and the filtration accuracy is 0.1mm. The mechanical filter uses a high-pressure pump to feed water, with a head of 80 meters, and automatically backwashes through the pressure difference between the inlet and outlet, and the pressure difference is set at 0.5kgf / cm 2 . The ceramic membrane module adopts the ceramic ultrafiltration membrane produced by Nanjing Jiusi Hi-Tech Co., Ltd., with a pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com