Blade of vertical wind driven generator

A technology for wind turbines and blades, applied in the field of blades, which can solve the problems that the size of the windward surface of the blades cannot be controlled, and it is difficult to prevent vertical wind turbines from failing or even being damaged, and achieve the effects of light weight, low resistance, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

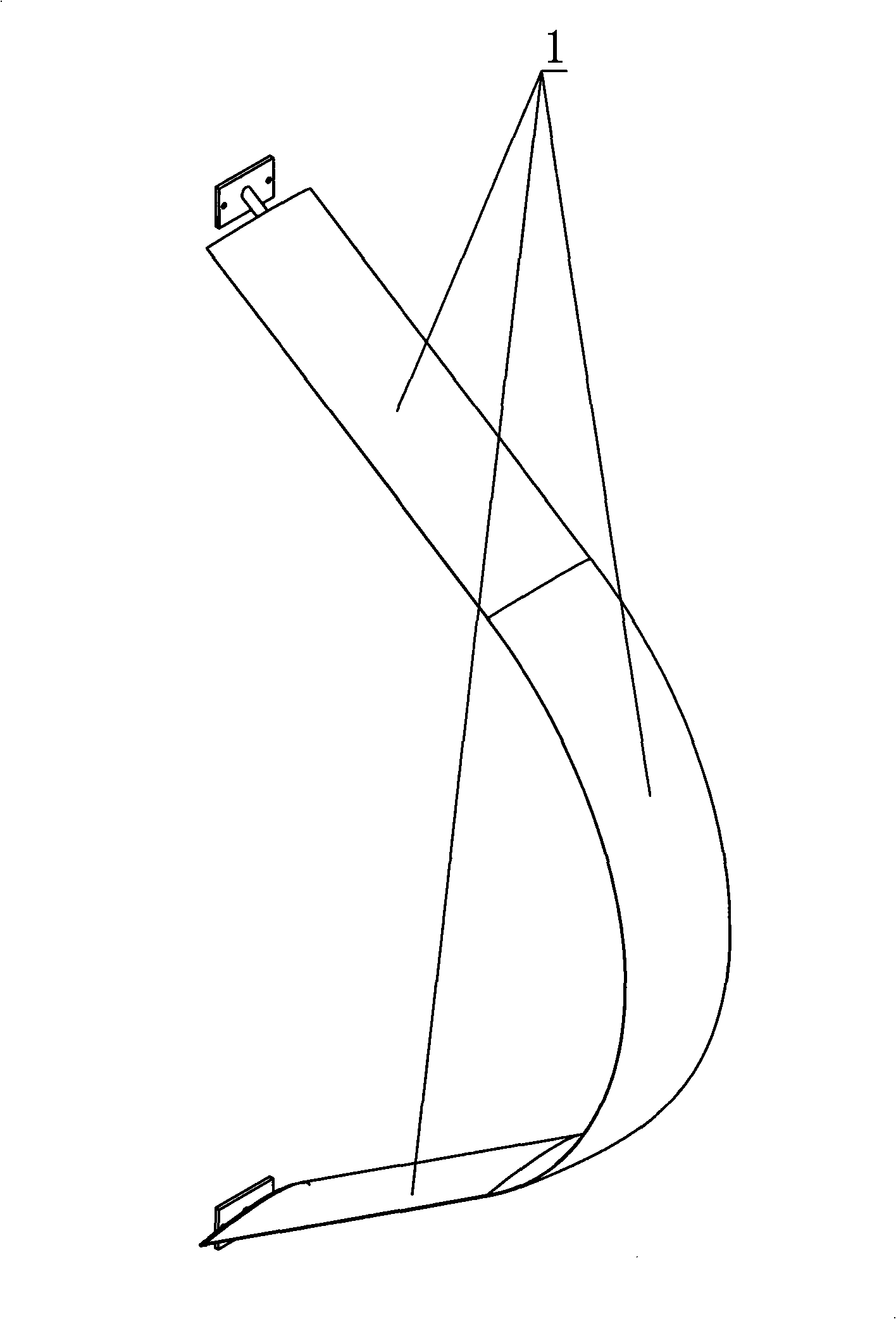

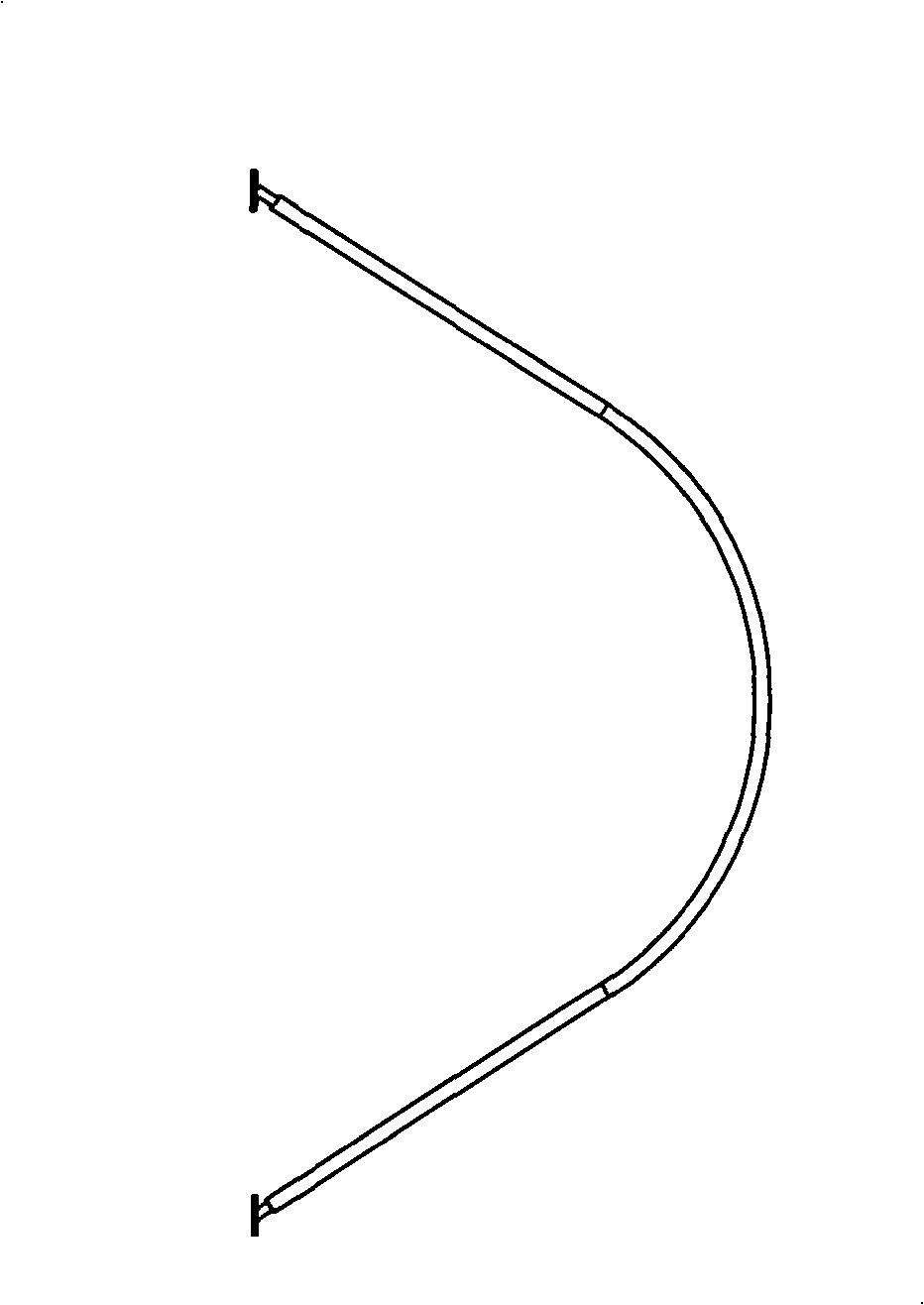

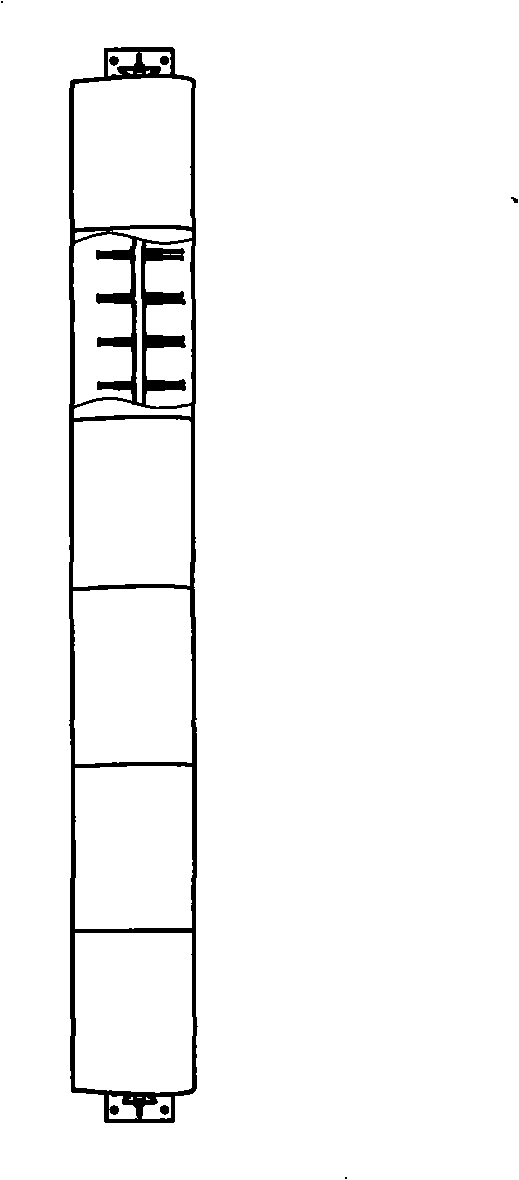

[0030] Such as Figure 1 to Figure 4 As shown in the vertical wind power generator blade, the blade is composed of three blade units 1; as Figure 4 , the cross-section of the blade unit 1 is olive-shaped with a large middle and small ends, and one of the two small ends is a round end, and the other end is a tip. The blade unit 1 adopts this cross-sectional structure, which has a high utilization rate of wind energy. The blade unit 1 includes a skeleton 101, a blade body 102, a first blade tip 103 and a second blade tip 104; the blade body 102 is installed on the skeleton 103, and the skeleton 103 is inside the blade body 102; The tip 103 is arranged at one end of the airfoil 102 along the radial direction of the blade unit 1, the tail portion 1031 of the first blade tip 103 is the round end, and the head 1032 of the first blade tip 103 extends into the airfoil 102 The second blade tip 104 is arranged on the end of the blade body 102 opposite to the first blade tip 103 along ...

no. 2 approach

[0033] Such as figure 1 , figure 2 , image 3 and Figure 8 As shown in the vertical wind power generator blade, the blade is composed of three blade units 1; as Figure 8 , the cross-section of the blade unit 1 is olive-shaped with a large middle and small ends, and one of the two small ends is a round end, and the other end is a tip. The blade unit 1 adopts this cross-sectional structure, which has a high utilization rate of wind energy. The blade unit 1 includes a skeleton 101, a blade body 102, a first blade tip 103 and a second blade tip 104; the blade body 102 is installed on the skeleton 103, and the skeleton 103 is inside the blade body 102; The tip 103 is arranged at one end of the airfoil 102 along the radial direction of the blade unit 1, the tail portion 1031 of the first blade tip 103 is the round end, and the head 1032 of the first blade tip 103 extends into the airfoil 102 The second blade tip 104 is arranged on the end of the blade body 102 opposite to the...

no. 3 approach

[0036] Such as figure 1 , figure 2 , image 3 and Figure 12 As shown in the vertical wind power generator blade, the blade is composed of three blade units 1; as Figure 12 , the cross-section of the blade unit 1 is olive-shaped with a large middle and small ends, and one of the two small ends is a round end, and the other end is a tip. The blade unit 1 adopts this cross-sectional structure, which has a high utilization rate of wind energy. The blade unit 1 includes a skeleton 101, a blade body 102, a first blade tip 103 and a second blade tip 104; the blade body 102 is installed on the skeleton 103, and the skeleton 103 is inside the blade body 102; The tip 103 is arranged at one end of the airfoil 102 along the radial direction of the blade unit 1, the tail portion 1031 of the first blade tip 103 is the round end, and the head 1032 of the first blade tip 103 extends into the airfoil 102 The second blade tip 104 is arranged on the end of the blade body 102 opposite to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com