Hydrogen chloride compressor

A technology of hydrogen chloride and compressors, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of small conveying capacity, high cost, pulsation of gas conveying pressure, etc., and achieve simple structure, long service life and conveying pressure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

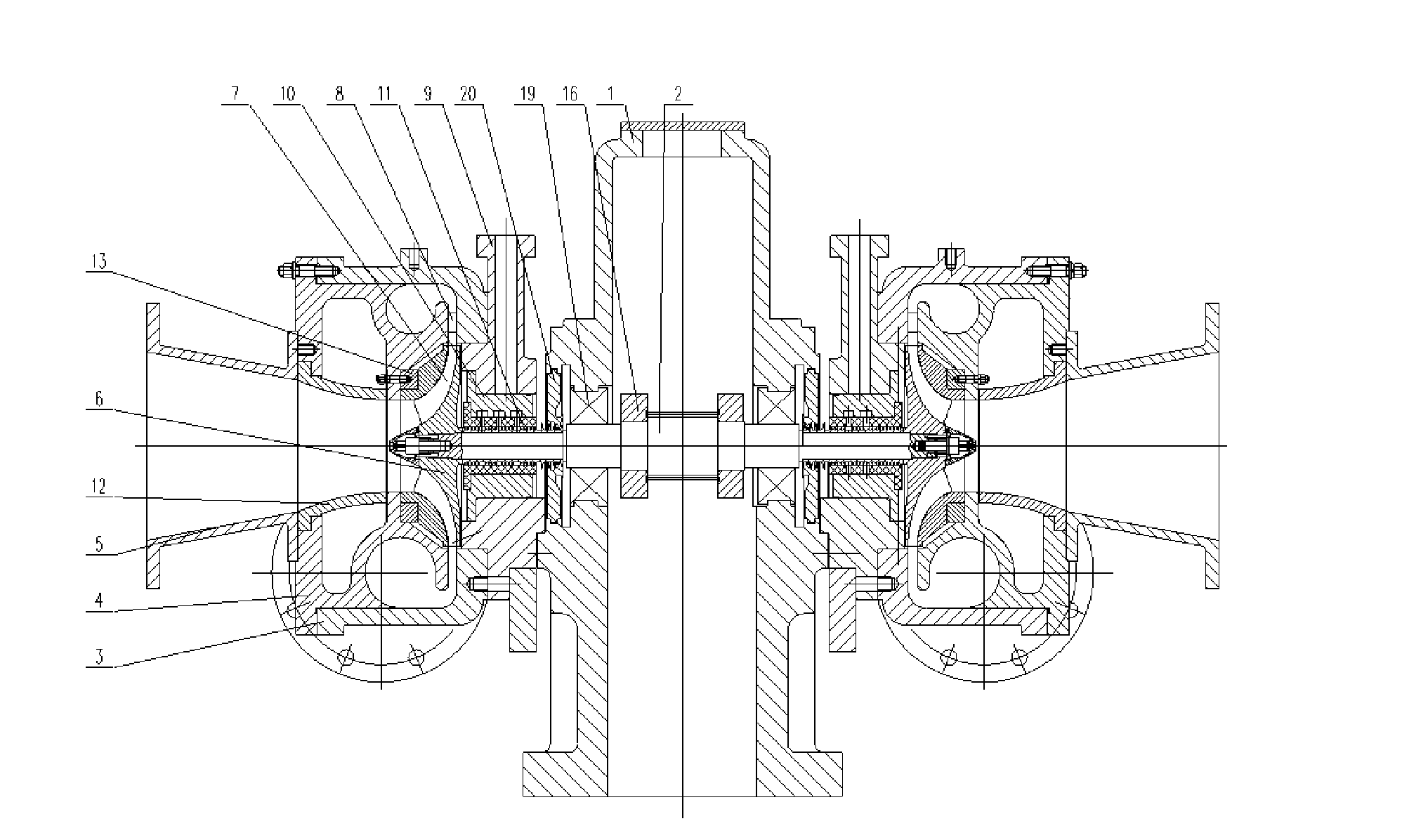

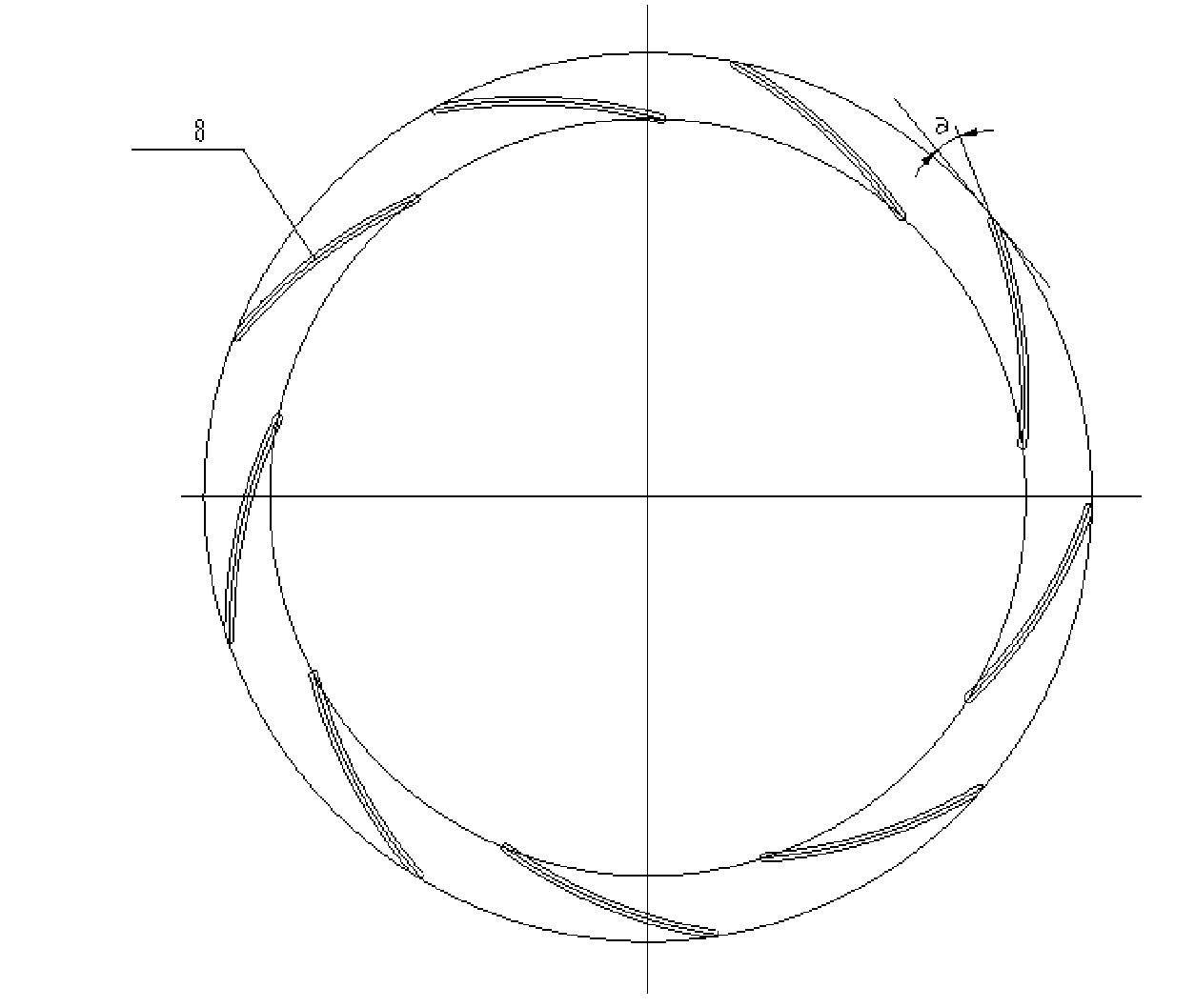

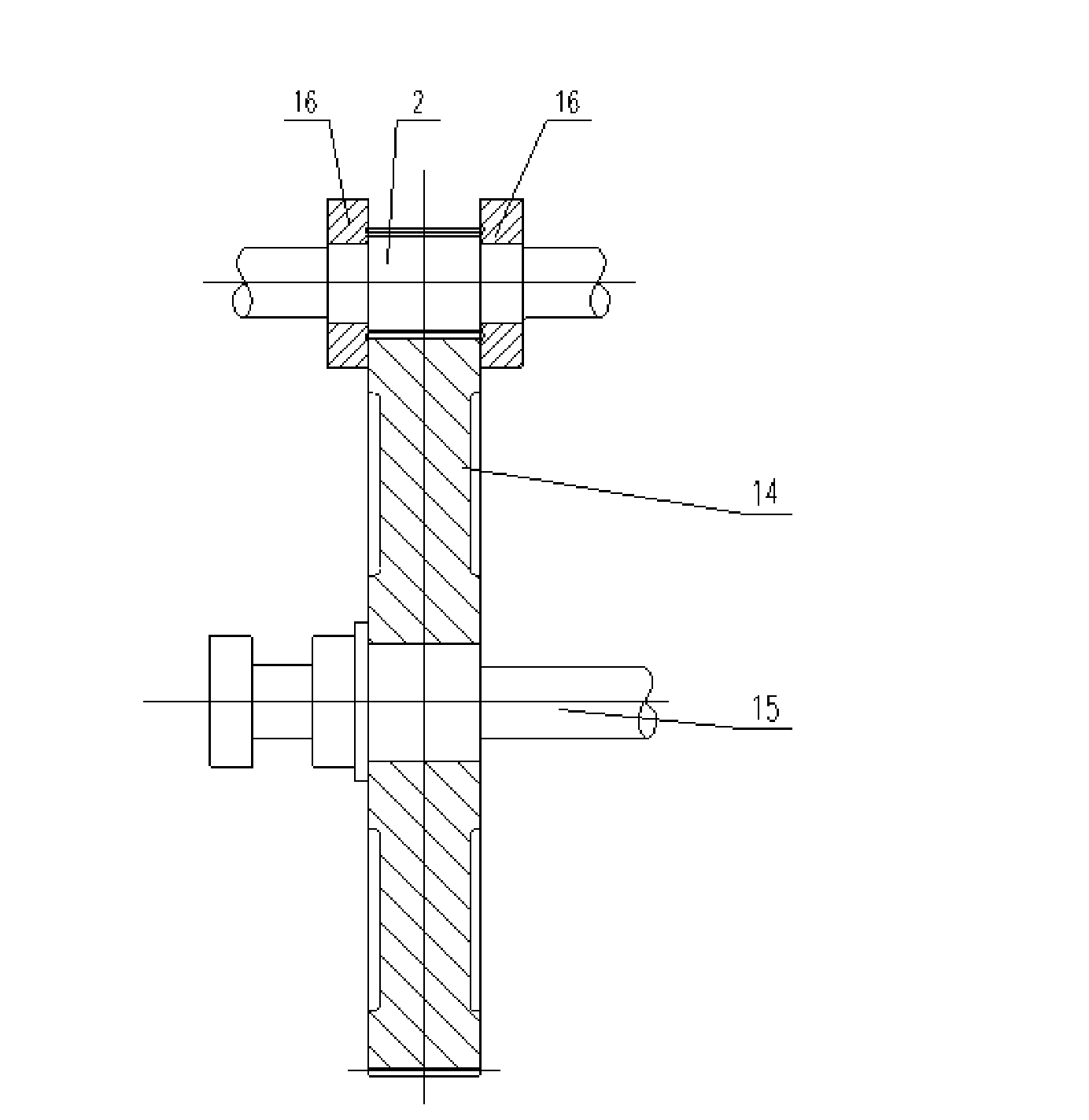

[0027] Embodiment 1: the hydrogen chloride compressor of this example, as figure 1 , image 3 , there is a gear speed-up box 1, the gear shaft 2 is connected through the gear speed-up box, the middle part of the gear shaft 2 is meshed with a large gear 14, the large gear is connected with a low-speed shaft 15, and the meshing part of the gear shaft 2 and the large gear 14 A thrust plate 16 is respectively connected to both sides. The two ends of the gear shaft 2 stretch out outside the gear speed-up box, and a tiltable pad sliding bearing 19 is arranged between the gear speed-up box and the gear shaft. Both sides of the gear speed increasing box 1 are respectively connected with a compression part, and the compression part includes an inlet pipe 5, a volute inner body 4, a stationary wheel cover 13, a volute 3 and an air seal assembly. Two inlet pipes 5 are connected to the opening of the volute inner body 4, and the inlet pipes are all arranged horizontally. The inside of ...

Embodiment 2

[0029] Embodiment 2: the hydrogen chloride compressor of this example, as Figure 4, there is a gear speed-up box 1, the gear shaft 2 is threaded through the gear speed-up box, the middle part of the gear shaft 2 is meshed with a bridge gear 17, and the bridge gear 17 is meshed with a large gear 14 through a medium-speed shaft 18, and the large gear wears A low-speed shaft 15 is connected, and a thrust plate 16 is respectively connected to both sides of the gear shaft 2 meshing with the bridge gear 17 . The two ends of the gear shaft 2 stretch out outside the gear speed-up box, and a tiltable pad sliding bearing 19 is arranged between the gear speed-up box and the gear shaft. Both sides of the gear speed increasing box 1 are respectively connected with a compression part, and the compression part includes an inlet pipe 5, a volute inner body 4, a stationary wheel cover 13, a volute 3 and an air seal assembly. The inlet pipe 5 is connected to the opening of the volute inner bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com