Composite process of transparent non-slip carpet

A composite process and transparent technology, applied in household components, applications, household appliances, etc., can solve the problems of high and low temperature changes, non-wear resistance, easy deformation, etc., and achieve the effect of clear texture, good anti-slip and smooth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

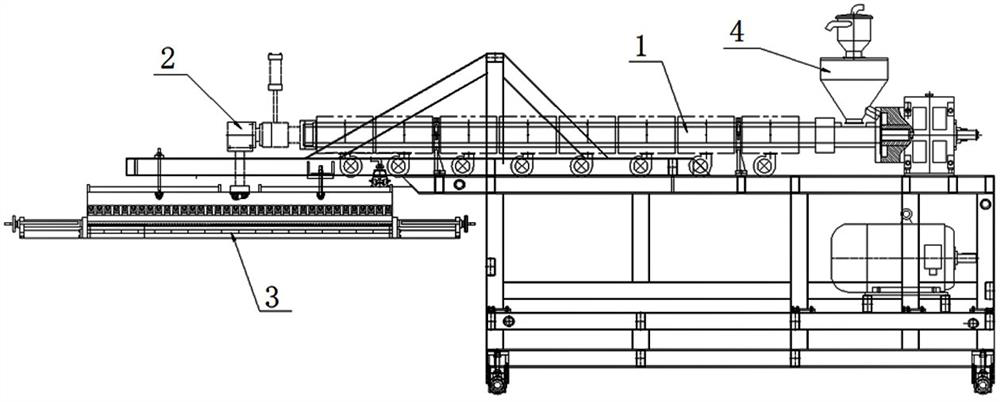

[0035] Embodiment 1: in combination with figure 1 , 2 Shown in and 3, a composite process of a transparent anti-slip carpet, the transparent anti-slip carpet is composed of a fabric layer and a TPE layer, the fabric layer is made of wool material, and the TPE layer is made of 85% styrene-butadiene oxide Composed of block copolymer and 15% polypropylene, it is compounded by a thin casting compound machine. The specific steps are as follows,

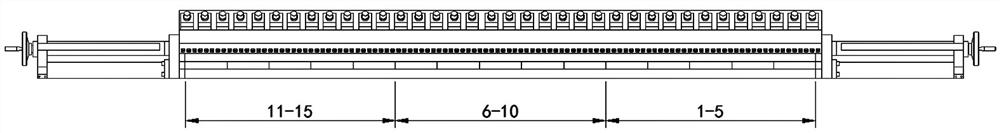

[0036] First, preheat the screw 1, the metal interface 2 and the mold 3 in the main machine. The screw 3 includes 9 heating zones, where the heating zone A is preheated to 100°C, the heating zone B is preheated to 120°C, and the heating zone C is preheated to 150°C, heating zone D is preheated to 180°C, heating zone E~I is preheated to 195°C; the interface 2 is preheated to 195°C; the mold 3 includes 15 heating zones, of which the first The preheating temperature of the 5th heating zone and the 11th to 15th heating zone is 195°C, and the...

Embodiment 2

[0042] Embodiment 2: the composite process of the second kind of transparent anti-slip carpet, the transparent anti-slip carpet is composed of a fabric layer and a TPE layer, the fabric layer is made of polyester material, and the TPE layer is made of 82% styrene-butadiene oxide Composed of block copolymer and 18% polypropylene, it is compounded by a thin casting compound machine. The specific steps are as follows,

[0043] First, preheat the screw 1, metal interface 2 and mold 3 in the host, and the whole preheating time is 58 minutes; while preheating the screw 1, interface 2 and mold 3 in the host, preheat the TPE material of transparent particles To 68 ℃ to remove the water vapor on the surface.

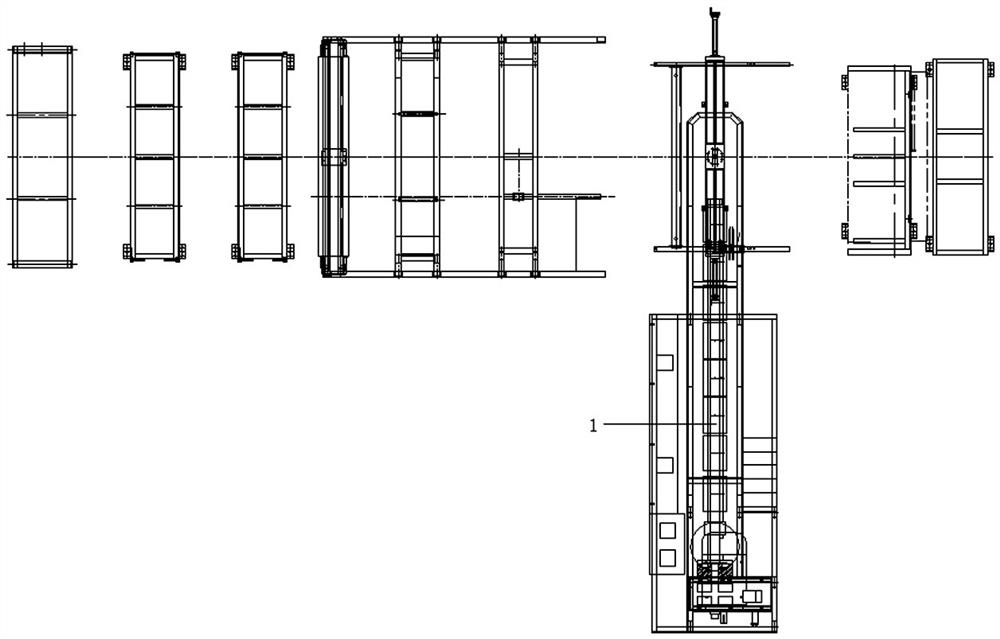

[0044] At the same time, the fabric layer enters between the rubber stick 5 and the embossing stick 6 after passing through the feeding device 10. At this time, the mold 3 is synchronously moved to the top of the rubber stick 5 and the embossing stick 6, and the TPE in the mold 3...

Embodiment 3

[0046] Embodiment 3: the composite process of the third kind of transparent anti-slip carpet, the transparent anti-slip carpet is formed by composite of fabric layer and TPE layer, and fabric layer adopts nylon material, and described TPE layer is made of 86% styrene-butadiene oxide Composed of block copolymer and 14% polypropylene, it is compounded by a thin tape casting compound machine. The specific steps are as follows,

[0047] First, preheat the screw 1, metal interface 2 and mold 3 in the host, and the whole preheating time is 62 minutes; while preheating the screw 1, interface 2 and mold 3 in the host, preheat the TPE material of transparent particles To 70 ℃ to remove the water vapor on the surface.

[0048] At the same time, the fabric layer enters between the rubber stick 5 and the embossing stick 6 after passing through the feeding device 10. At this time, the mold 3 is synchronously moved to the top of the rubber stick 5 and the embossing stick 6, and the TPE in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com