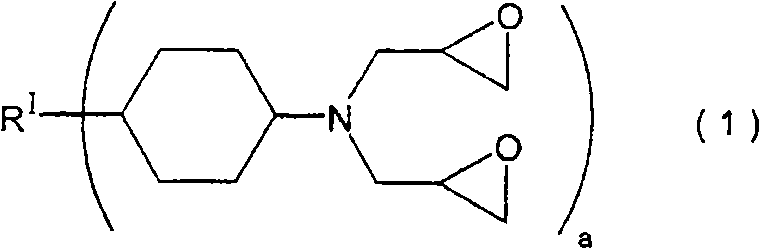

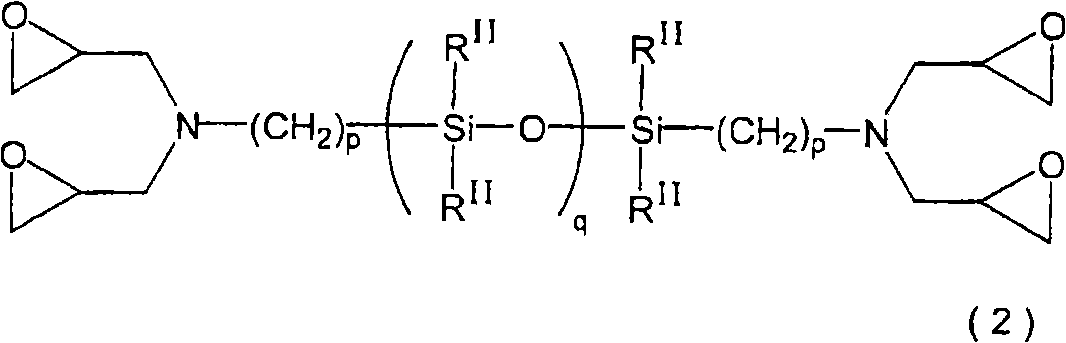

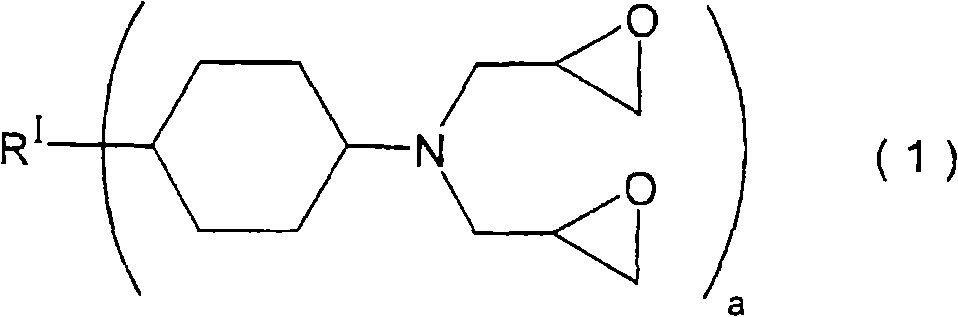

Aligning agent for liquid crystal and liquid crystal display element

A technology of liquid crystal aligning agent and polymer, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as damage to liquid crystal orientation, and achieve the effect of good coating and excellent film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0139] 109 g (0.50 mol) of pyromellitic dianhydride as tetracarboxylic dianhydride and 98 g (0.50 mol) of 1,2,3,4-cyclobutane tetracarboxylic dianhydride, and 4 as diamine compound, 200g (1.0 mole) of 4-diaminodiphenyl ether was dissolved in a mixed solvent made of 244g N-methyl-2-pyrrolidone and 2200g γ-butyrolactone, and after reacting for 3 hours at 40°C, 1220g γ- butyrolactone to obtain about 4070 g of a solution containing 10% by weight of polyamic acid (A-1). The solution viscosity of this solution was 200 mPa·s.

Synthetic example 2

[0141] 98 g (0.50 moles) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride and 109 g (0.50 moles) of pyromellitic dianhydride, and 4 as diamine compound, 198g (1.0mol) of 4'-diaminodiphenylmethane was dissolved in a mixed solvent made of 243g N-methyl-2-pyrrolidone and 2190g γ-butyrolactone, and after reacting at 40°C for 3 hours, an additional 1210g was added γ-butyrolactone to obtain about 4050 g of a solution containing 10% by weight of polyamic acid (A-2). The solution viscosity of this solution was 125 mPa·s.

Synthetic example 3

[0143] 196g (1.0 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride and 200g (1.0 mol) of 4,4'-diaminodiphenyl ether as diamine compound ) was dissolved in a mixed solvent made of 238g N-methyl-2-pyrrolidone and 2130g γ-butyrolactone, after reacting for 4 hours at 40°C, 1190g γ-butyrolactone was added to obtain about 3960g poly A solution of amic acid (A-3). The solution viscosity of this solution was 210 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com