Method for generating ring-cutting roughing NC tool path of product triangular mesh model

A triangular mesh and rough machining technology, applied in simulators, instruments, computer control, etc., can solve problems such as restricting the scope of application, poor algorithm applicability, ineffective extraction of triangular mesh models, etc., to achieve strong algorithm adaptability. Effect

Inactive Publication Date: 2011-01-05

SHANDONG UNIV OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The prior art literature search found that Liu Lei et al. published the academic paper "Layer Cut Method CNC Machining Based on Profile Measurement Data" in the academic journal "Journal of Huazhong University of Science and Technology" 1999, 27 (2): P10-12. The profiling measurement data is divided into a triangular polyhedron model, and the triangular polyhedron model is intersected with the cutting plane to obtain the contour ring. The processing area is determined according to the topological relationship between the contour rings, and the contour ring is offset to generate the NC tool path for rough machining. The size and shape of the tool selected during the machining process must be consistent with the probe, which seriously restricts its application range and the algorithm has poor applicability

In the academic paper "Management of Multi-solid Section Profile Ring and Automatic Boundary Extraction" published in the academic journal "Computer Engineering and Design" 2003, 24(11): P119-12, Liu Fen et al. Carry out layering and obtain closed contour rings, use the binary tree to organize the topological relationship between the contour rings, determine the processing area, and generate ring cutting rough machining NC tool paths by offsetting the contour rings. This method is only applicable to solid models and cannot Generate correct machining tool paths for unclosed triangular mesh models

To sum up, the methods described in the existing literature cannot effectively extract the contour ring of the general triangular mesh model, and establish the corresponding topological relationship to realize the generation of the ring cutting tool path. Based on the triangular mesh model, the rapid Generating circumcision rough machining NC tool paths has become a technical problem to be solved urgently by those skilled in the art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

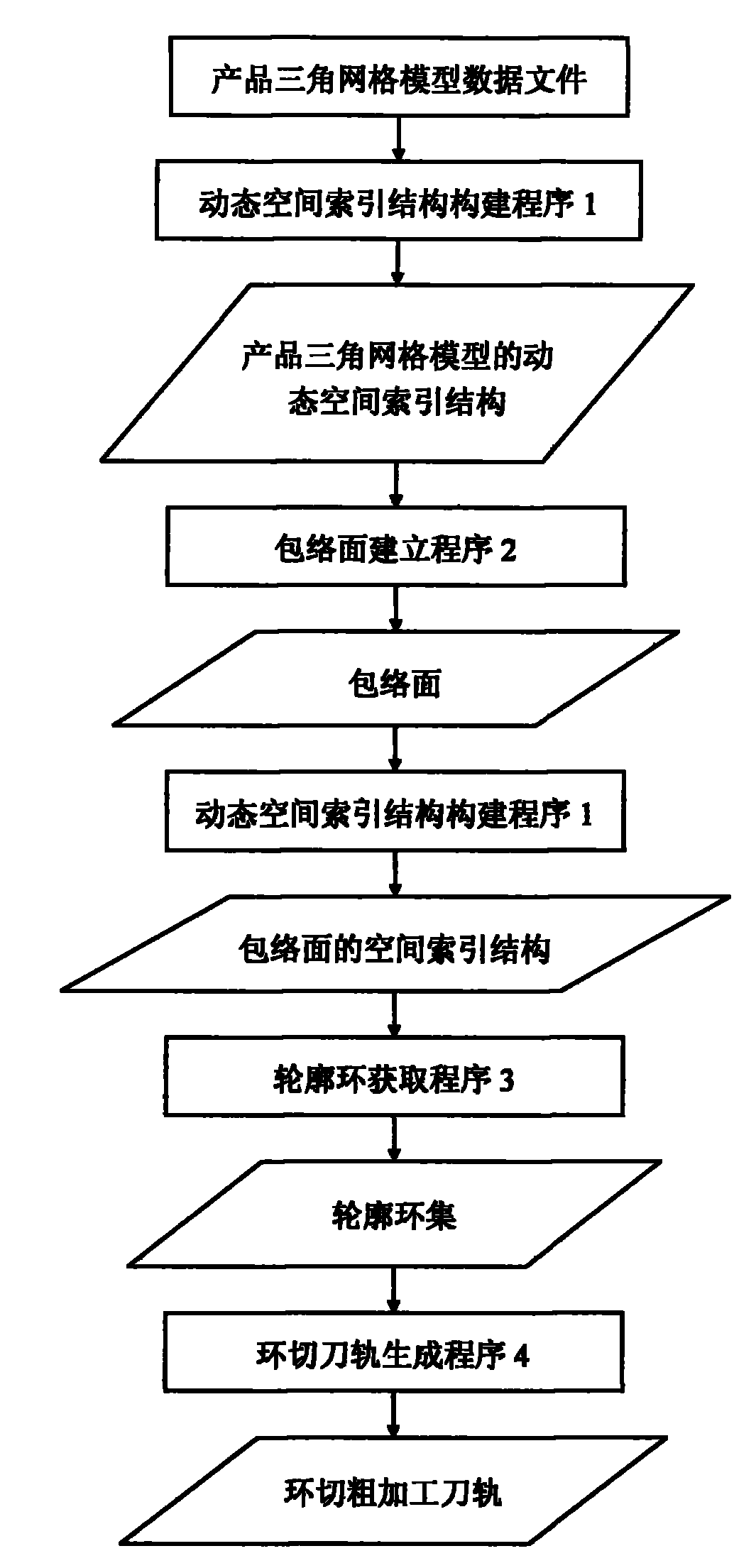

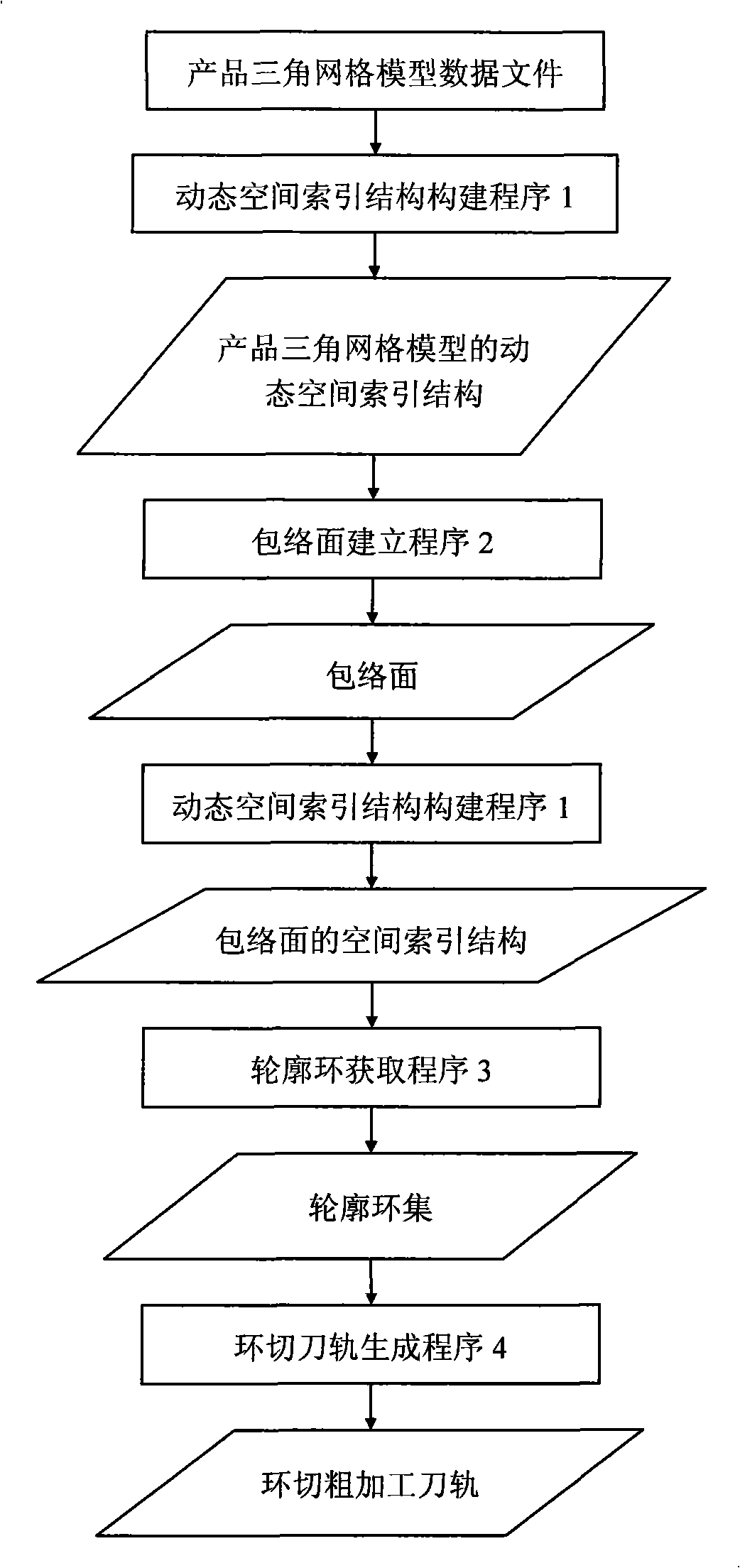

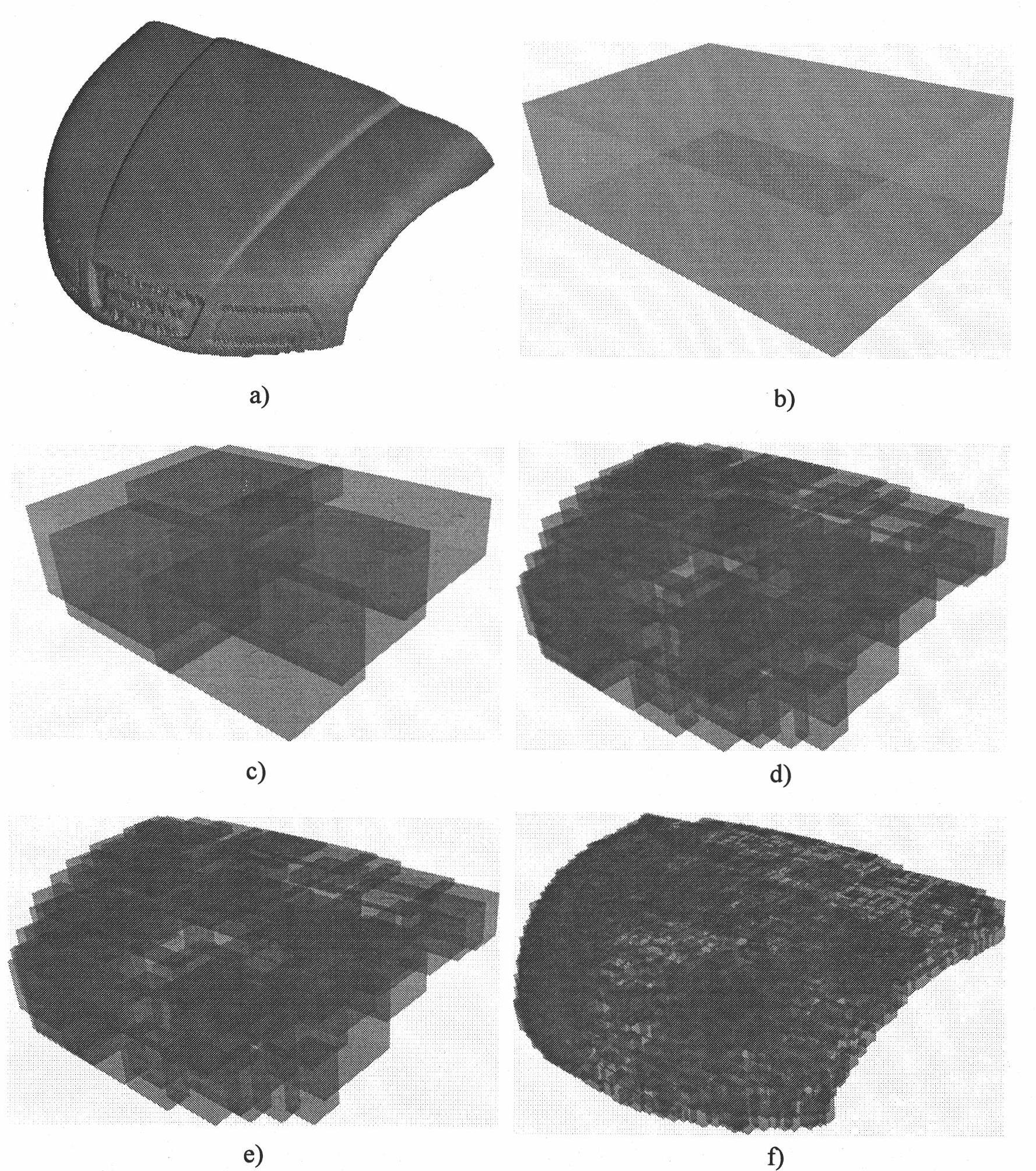

The invention provides a method for generating a ring-cutting roughing NC tool path of a product triangular mesh model. The method is characterized in that an R<*> S-tree dynamic space index structure is used for organizing the topological neighbor relation of the product triangular mesh model; based on the dynamic space index structure, a Z-oriented enveloping surface of the product triangular mesh model is established fast; an R<*> S-tree is used for establishing the dynamic space index structure of the enveloping surface; based on the structure, the enveloping surface and a cutting plane are calculated intersection to obtain each contour loop; the directions of the contour loops are adjusted one by one to establish the topological relation of each contour loop for confirming a processing area; and isometric offset is carried out on the contour loops to obtain the ring-cutting roughing tool path. The embodiment proves that the algorithm can generate the ring-cutting roughing tool path of various product triangular mesh models, and the algorithm has strong adaptability.

Description

NC Tool Path Generation Method for Circular Rough Machining of Product Triangular Mesh Model technical field The invention provides a method for generating an NC tool path for circumcision and rough machining of a triangular mesh model of a product, and belongs to the technical field of computer-aided manufacturing. Background technique In product reverse engineering, equipment such as laser scanners is usually used to obtain scattered point cloud data on the surface of the product solid model, and the data is triangulated to generate a triangular mesh model, which approximates the original solid model. Direct generation based on triangular mesh model The CNC machining tool path can avoid the reconstruction process of the product CAD model and the cumulative error of the model reconstruction, thereby effectively improving the product development efficiency and machining accuracy based on reverse engineering. The prior art literature search found that Liu Lei et al. publ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/4099

Inventor 孙殿柱崔传辉刘健朱昌志

Owner SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com