A remote pump optic fiber amplifying module

A technology of optical fiber amplification and remote pumping, which is applied in optics, light guides, lasers, etc., can solve problems such as difficult operation, inability to transmit optical signals, and inability to realize optical signal transmission, and achieve the effects of increasing scanning area, expanding functions, and optimizing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

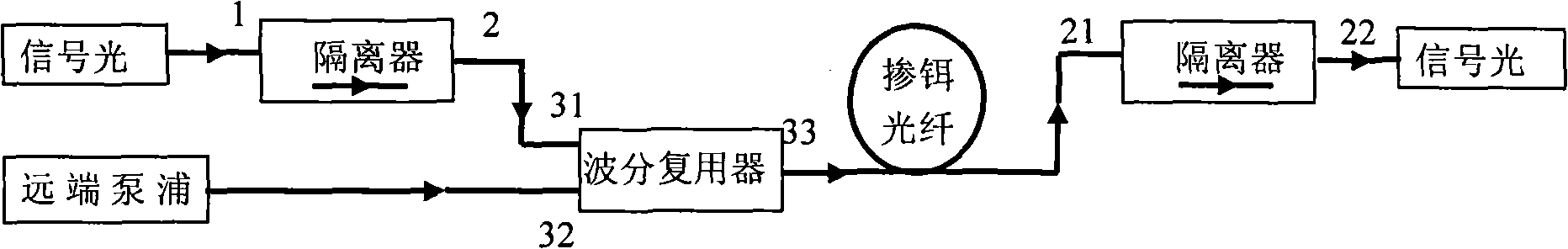

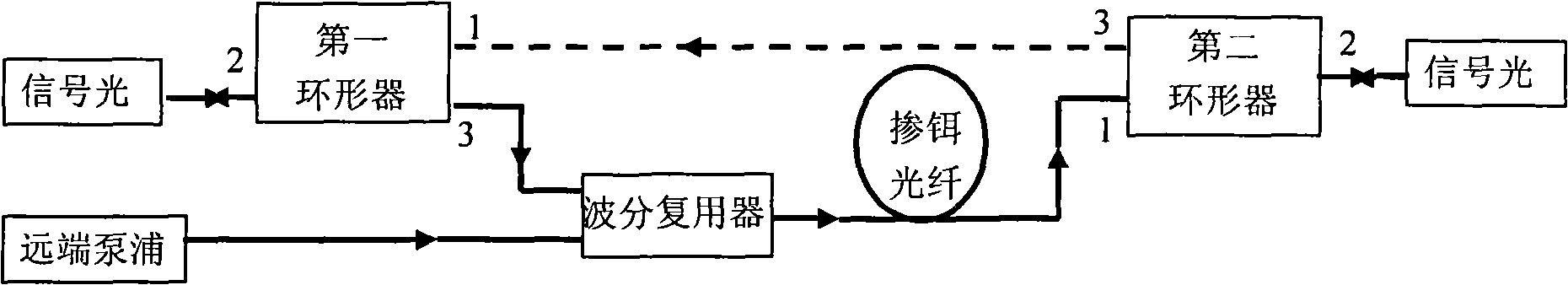

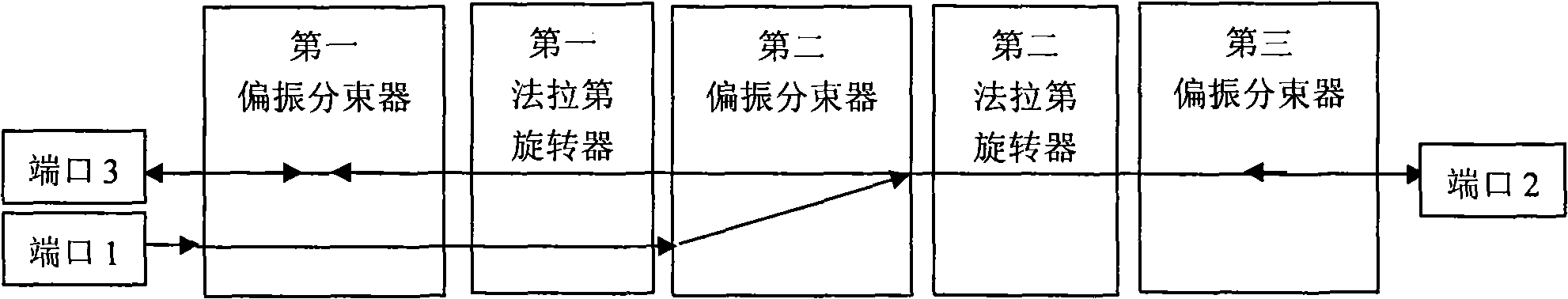

[0011] A remote pump optical fiber amplification module of the present invention such as figure 2 As shown, its interior is composed of two three-port circulators, a wavelength division multiplexer and at least one section of erbium-doped optical fiber. Port 1 of the first circulator of the above two circulators is connected to port 3 of the second circulator, port 3 of the first circulator is connected to one of the input terminals of the wavelength division multiplexer, and the output port of the wavelength division multiplexer It is connected to port 1 of the second circulator, the optical signal is input from port 2 of the first circulator, and output from port 2 of the second circulator. The erbium-doped optical fiber can be connected in series between the input end of the wavelength division multiplexer and the first circulator, or between the output end of the wavelength division multiplexer and the second circulator, or at the same time. terminal and the first circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isolation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com