Method for preparing a synthetic talc composition from a kerolite composition

A composition, serpentine technology, applied in the direction of silicon compounds, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as inability to obtain satisfactory quality crystallinity and thermally stable talc compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] A / -Synthetic Scheme of Synthetic Talc Composition

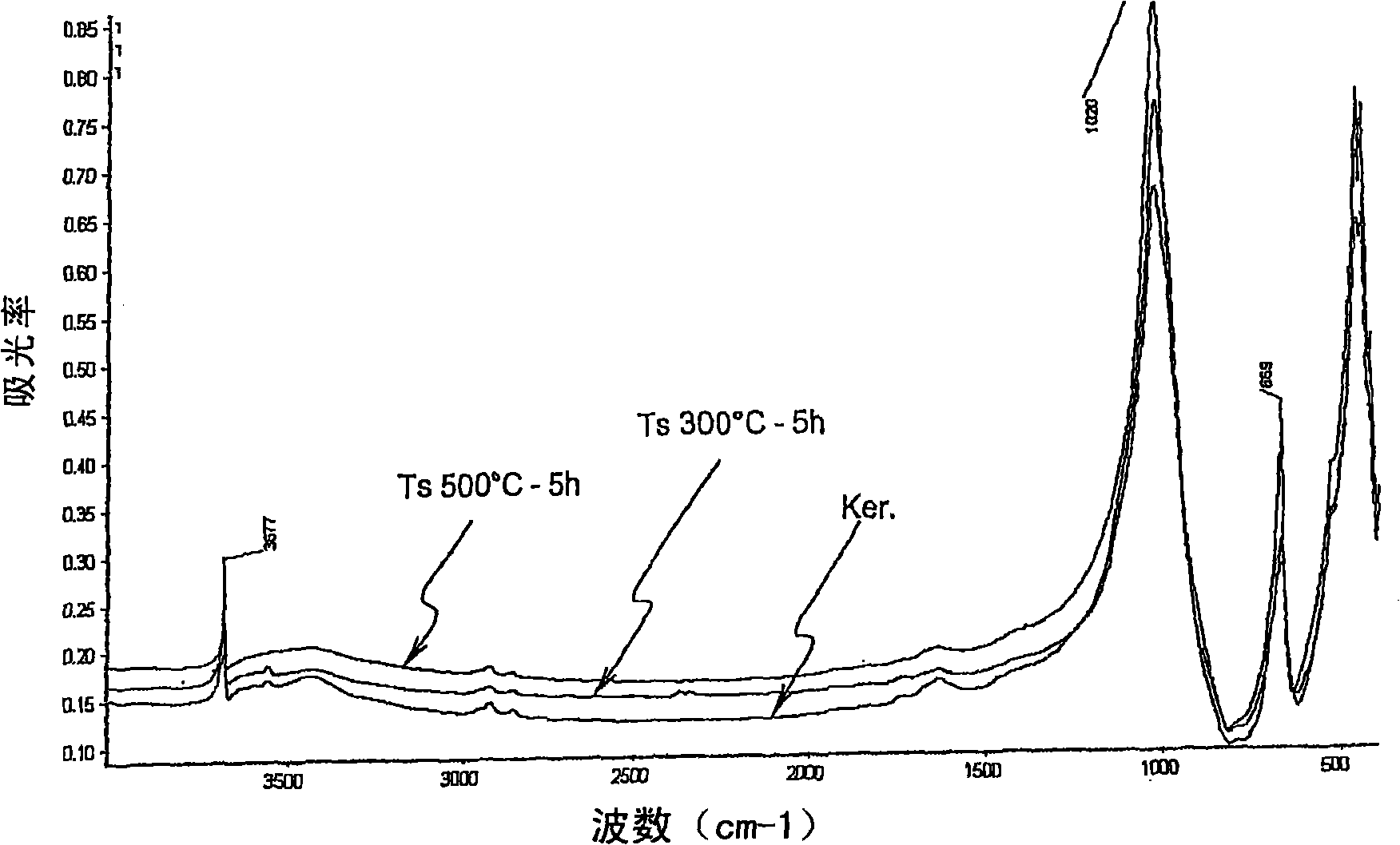

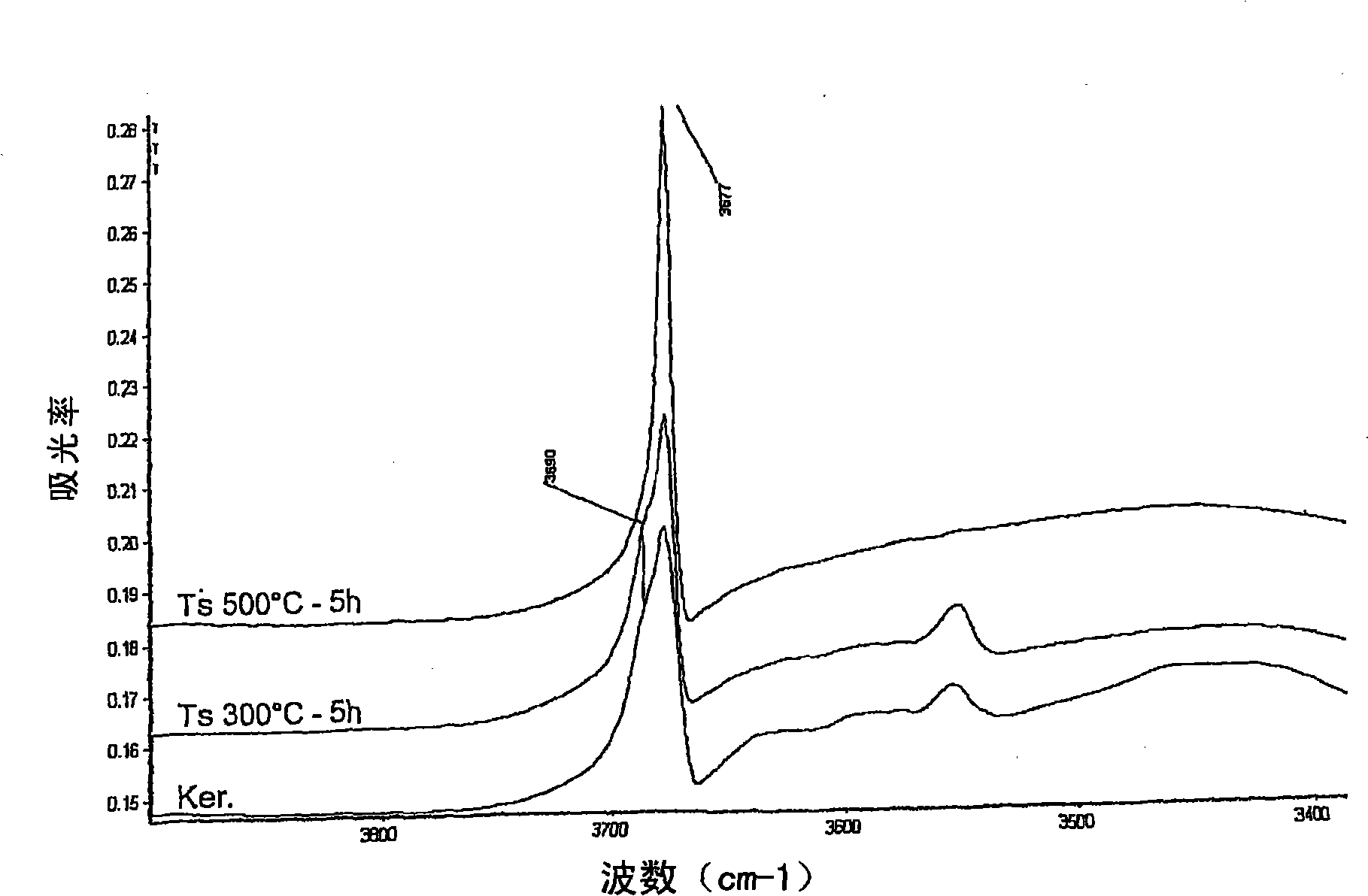

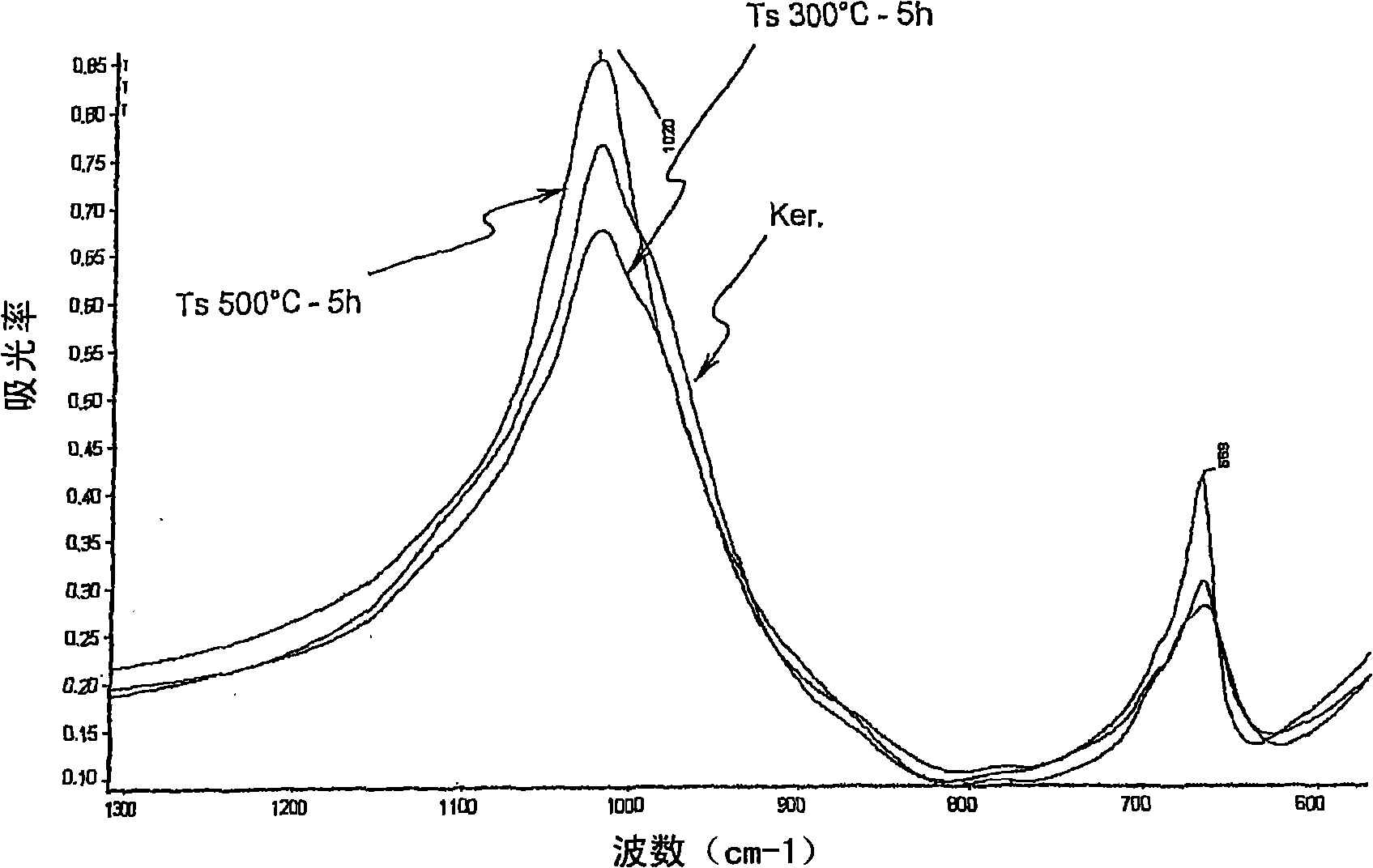

[0058] According to the present invention, the preparation of the synthetic talc composition comprises anhydrous thermal treatment of the cerolite composition. The anhydrous heat treatment is carried out at low pressure, less than 5 bar (for example at atmospheric pressure), and at a temperature greater than 300°C.

[0059] Although the focus of the present invention is essentially on this anhydrous heat treatment step, the preferred method of preparing the silicometallic gel and the preferred method of processing the gel to obtain the cerolite composition will also be described below. The anhydrous heat treatment according to the invention enables the conversion of cerolite to perfectly crystalline and thermally stable talc. Depending on the characteristics of the starting cerolite and the method used to prepare the cerolite, the particle size of the talc can be determined and adjusted.

[0060] 1 / - Preparation of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com