Electronic air throttle body for non-contact sensor

An electronic throttle body, non-contact technology, applied in electrical control, machine/engine, fuel injection control, etc., can solve problems such as inability to meet the throttle valve, poor high-speed performance, etc., and achieve easy servo control, high precision, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

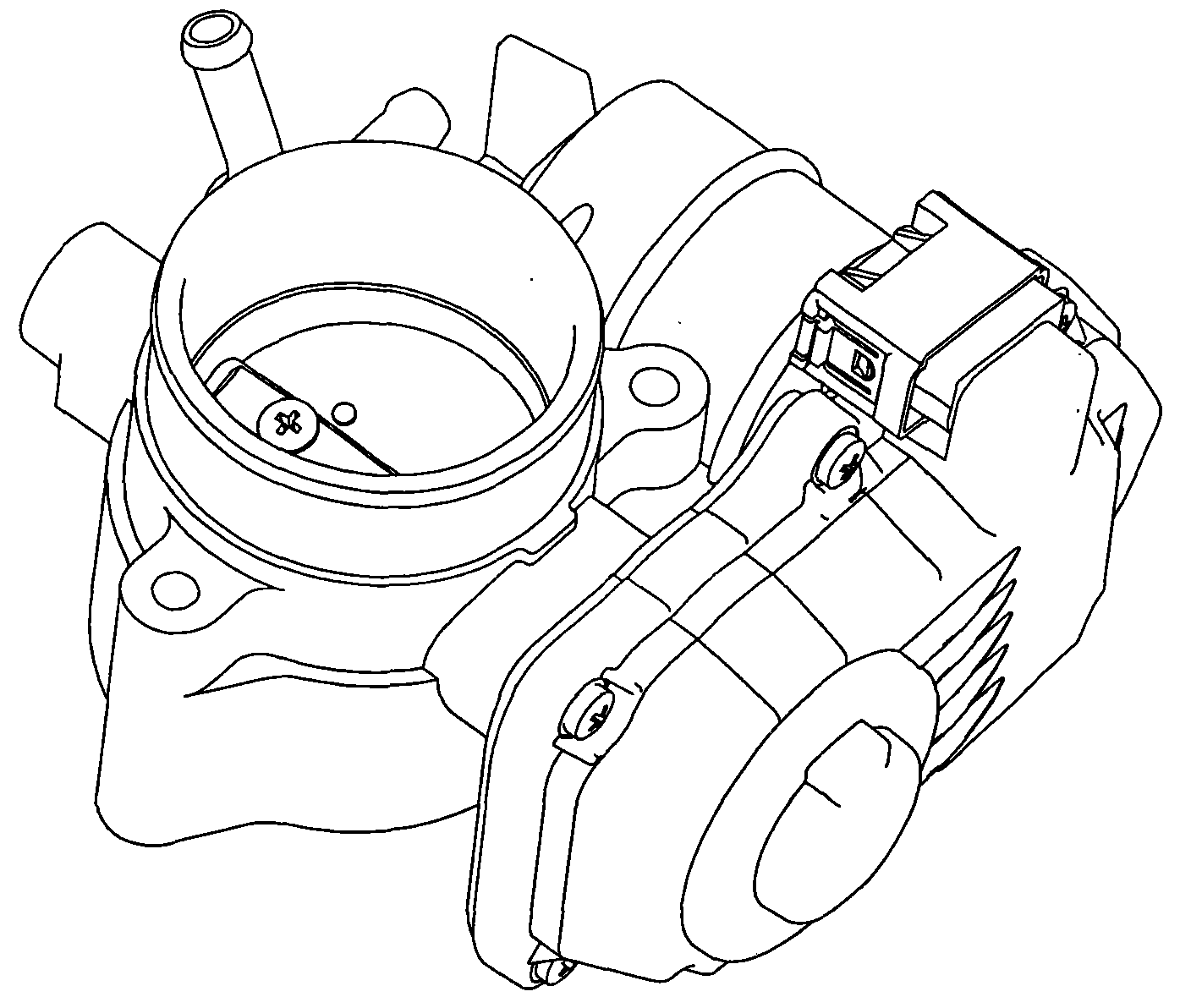

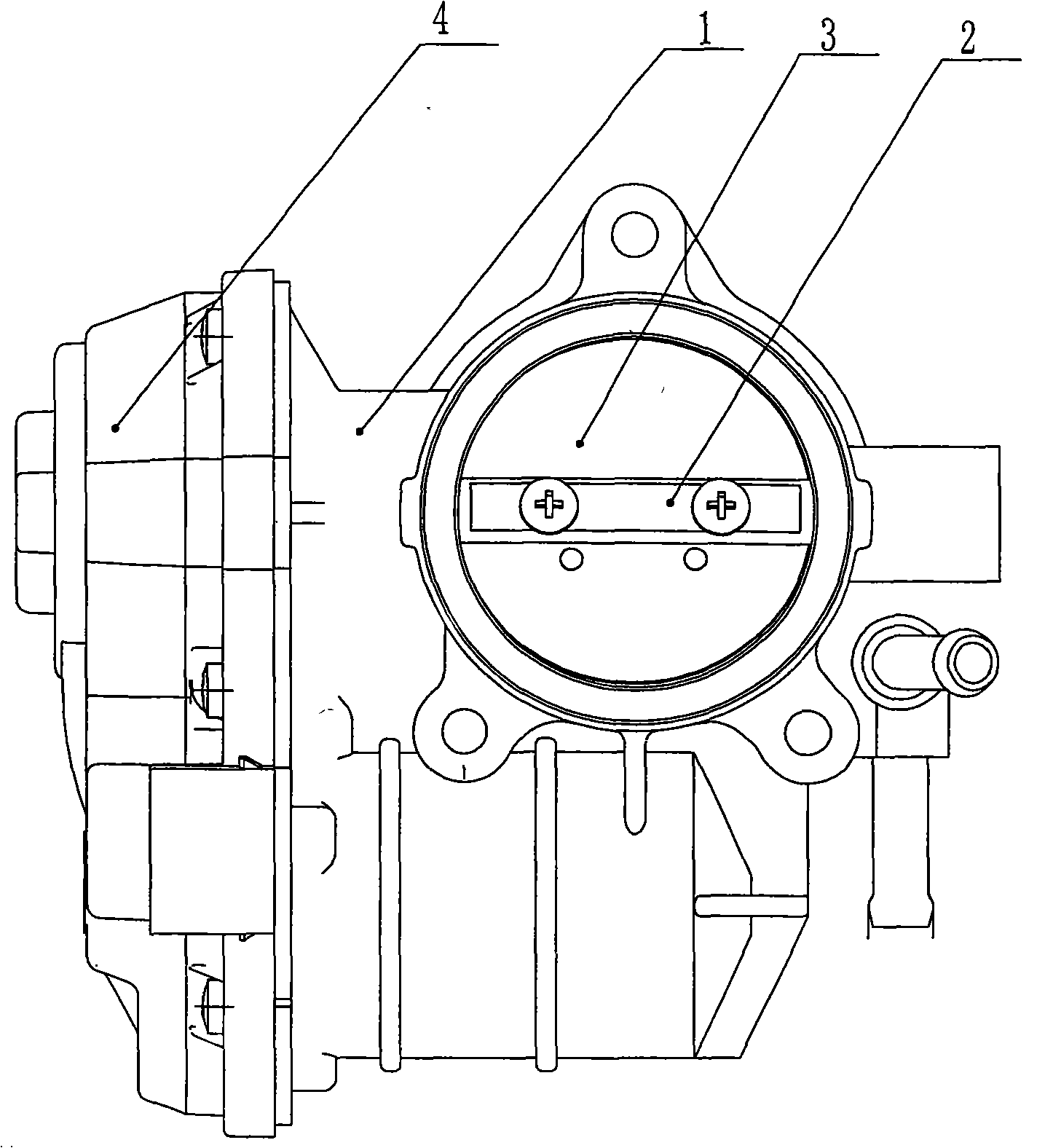

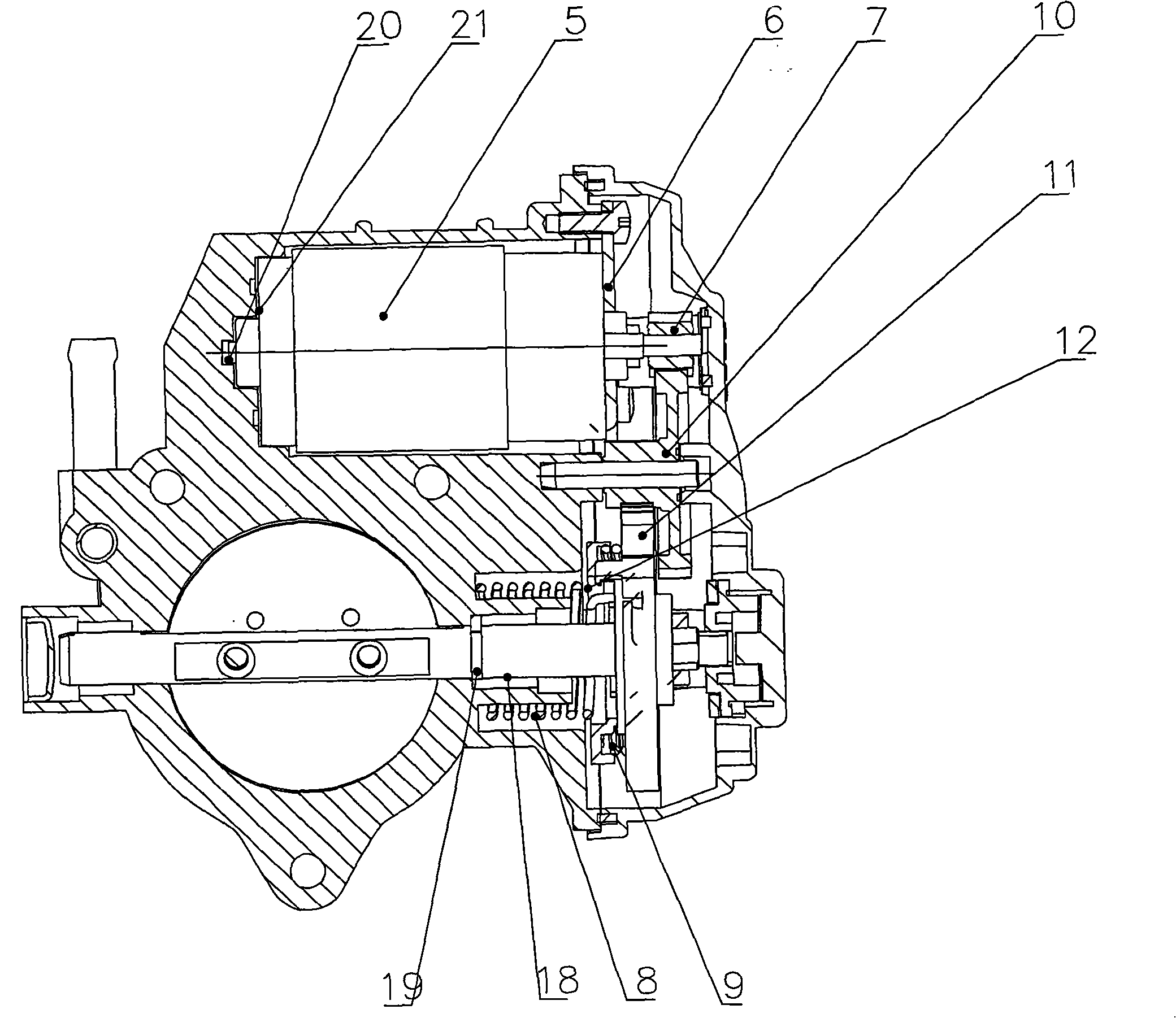

[0026] figure 1 figure 2 image 3 Figure 4 It shows that the electronic throttle body provided by the present invention includes a throttle body 1, a throttle valve plate 3, a throttle shaft 2, a sensor assembly, a motor assembly (including a DC motor 5), an intermediate gear, a sector gear assembly and a torsion spring . Figure 4 As shown, the position blocking mechanism is mainly composed of throttle shaft, sector gear 11, torsion spring 8, torsion spring 9 and two protruding limit stops 14,15 on the throttle body. One end of the torsion spring 8 is fixed on the throttle body, and the other end is fixed on the sector gear on the throttle shaft. Due to the torsion force of the torsion spring 8, the gear cover stopper 17 reaches the limit stopper of the body in a natural state. 14, so that the throttle valve plate is kept at a high idle speed state (it can also be said that the opening of the throttle valve plate corresponds to a high idle speed state), and when the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com