Package structure of light emitting diode and the packaging method thereof

A technology of light-emitting diodes and packaging methods, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of affecting the light emission angle, limiting the light emission angle, etc., and achieve the effect of easy control and wide light emission angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

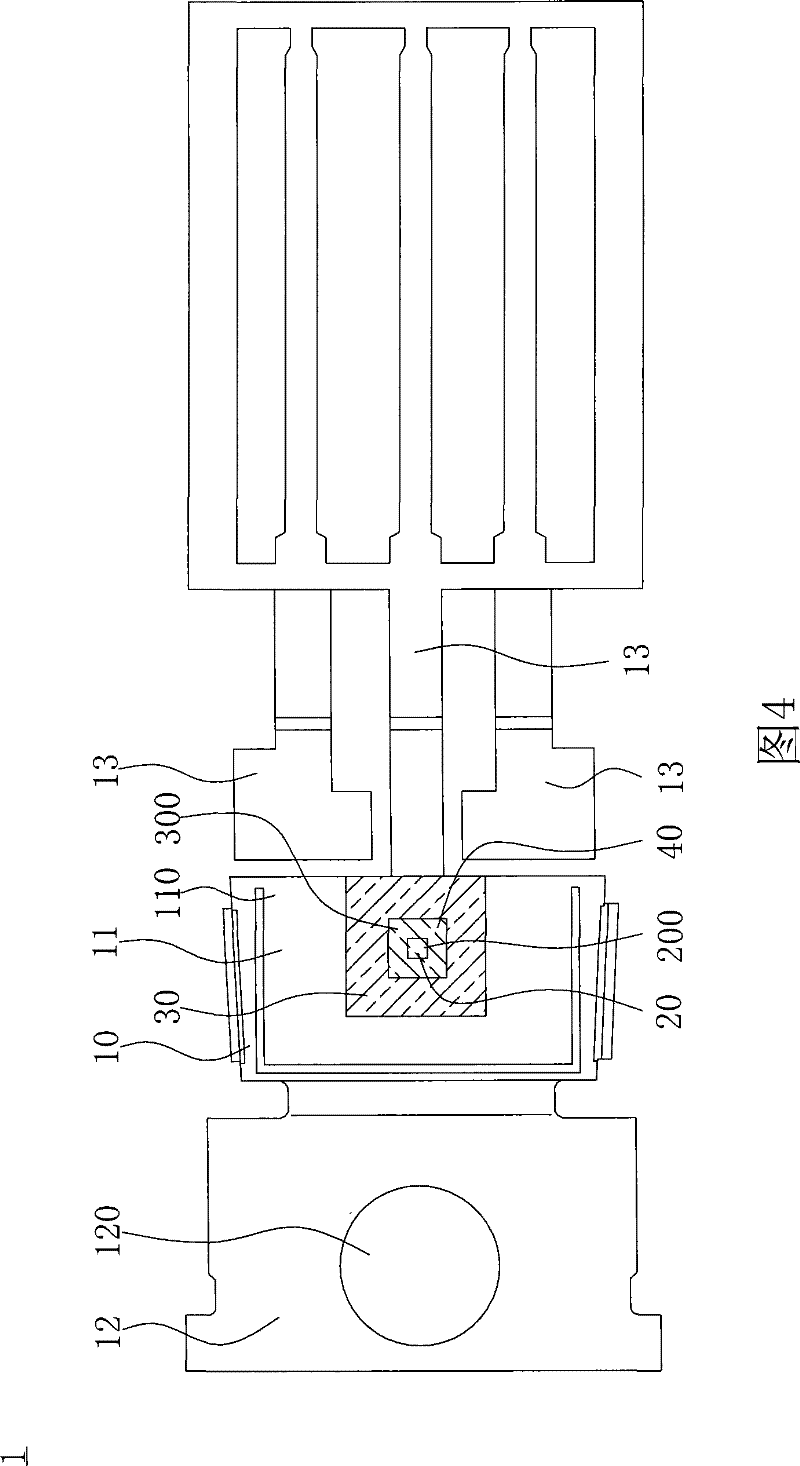

[0046] see Figure 4 and Figure 5 , which shows a schematic plan view and a side view of a preferred embodiment of the packaging structure of the light emitting diode of the present invention. As shown in the figure, the LED packaging structure 1 of this embodiment includes: a substrate 10 , a LED unit 20 , a light-transmissive filling fixing seat 30 and a colloid unit 40 .

[0047] Such as Figure 4 and Figure 5 As shown, the substrate 10 can be made of aluminum substrate, copper substrate or silver substrate. In this embodiment, the substrate 10 is a diode support structure, and its material is a copper substrate. The substrate 10 has a main body portion 11, a top portion 12 and a pin portion 13, and the top portion 12 and the pin portion 13 can be respectively formed on two opposite ends of the main body portion 11; wherein, the main body portion 11 has a The packaging surface 110 for accommodating the LED unit 20 and the glue unit 40, the top 12 has a pair of alignm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com