A kind of production technology of styrene-maleic anhydride copolymer

A production process, technology of maleic anhydride, applied in the field of production process of styrene/maleic anhydride copolymer, can solve problems such as inability to stop reaction and control reaction amount at any time, achieve good product stability, uniform product structure, suitable for The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

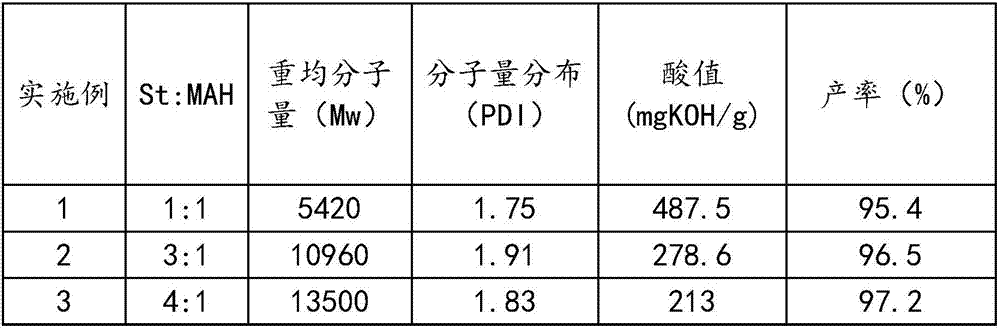

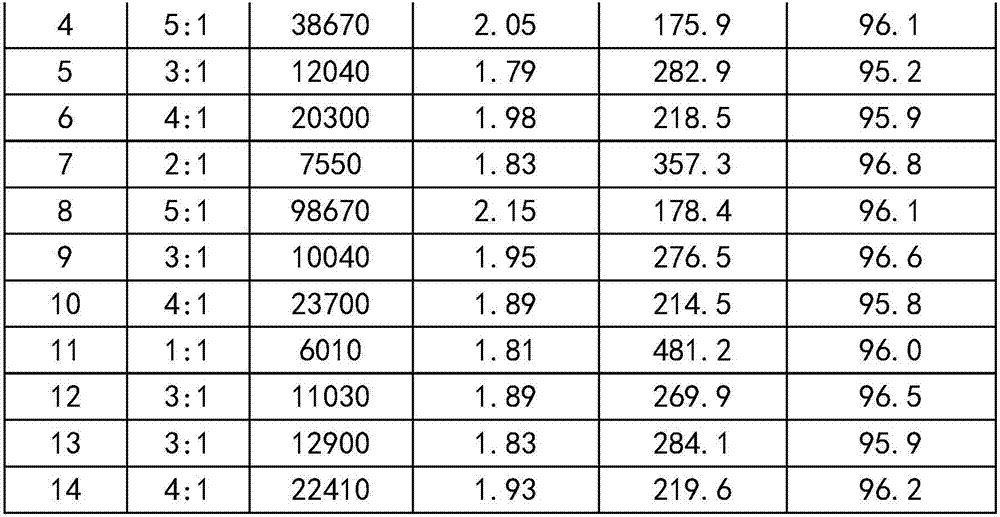

Embodiment 1

[0062] 77.6 kg of maleic anhydride and 8.0 kg of azobisisobutyronitrile were simultaneously dissolved in 80.0 kg of butanone to prepare reaction solution A; 82.3 kg of styrene was reaction solution B.

[0063] The reaction medium in the reaction kettle is 160.0 kg butanone, and the temperature of the reaction medium in the reaction kettle is controlled at 80° C. through an oil bath. Reaction solution A and reaction solution B are continuously dripped into the reactor simultaneously with different pipelines respectively, and the feed rate of control reaction solution A is 0.460kg / min, and the feed rate of control reaction solution B is 0.229kg / min. Liquid A and reaction liquid B were added dropwise for 6 hours at the same time, and reacted for 1 hour after the dropwise addition to end the reaction. After raising the temperature and distilling butanone under reduced pressure, the material in the reactor is melted and discharged, and a solid SMA product is obtained after cooling....

Embodiment 2

[0065] Dissolve 5.4kg of azobisisobutyronitrile in 60.0kg of methyl ethyl ketone to prepare reaction solution A; 25.8kg of maleic anhydride and 82.3kg of styrene are mixed and dissolved to form reaction solution B.

[0066] The reaction medium in the reaction kettle is 103.5 kg butanone, and the temperature of the reaction medium in the reaction kettle is controlled at 70° C. through an oil bath. Reaction solution A and reaction solution B are continuously dripped into the reactor simultaneously with different pipelines respectively, and the feed rate of control reaction solution A is 0.136kg / min, and the feed rate of control reaction solution B is 0.225kg / min. Solution A and reaction solution B were added dropwise for 8 hours at the same time, and reacted for 2 hours after the dropwise addition to end the reaction. After raising the temperature and distilling butanone under reduced pressure, the material in the reactor is melted and discharged, and a solid SMA product is obta...

Embodiment 3

[0068] 19.4kg of maleic anhydride and 5.1kg of azobisisobutyronitrile were dissolved in 25.0kg of methyl ethyl ketone to prepare reaction solution A; 82.3kg of styrene was reaction solution B.

[0069] The reaction medium in the reaction kettle is 45.0 kg butanone, and the temperature of the reaction medium in the reaction kettle is controlled at 80° C. through an oil bath. Reaction solution A and reaction solution B are continuously dripped into the reactor simultaneously with different pipelines respectively, and the feed rate of control reaction solution A is 0.215kg / min, and the feed rate of control reaction solution B is 0.274kg / min. Solution A and reaction solution B were added dropwise for 5 hours at the same time, and reacted for 1 hour after the dropwise addition to end the reaction. After raising the temperature and distilling butanone under reduced pressure, the material in the reactor is melted and discharged, and a solid SMA product is obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com