A kind of low-cost composite high-efficiency exothermic agent for converter and preparation method thereof

A heating agent and low-cost technology, applied in the field of metallurgy, can solve the problems of high raw material cost, unfavorable slagging process, insufficient heat generation, etc., and achieve the effects of high heating efficiency, controllable particle size and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

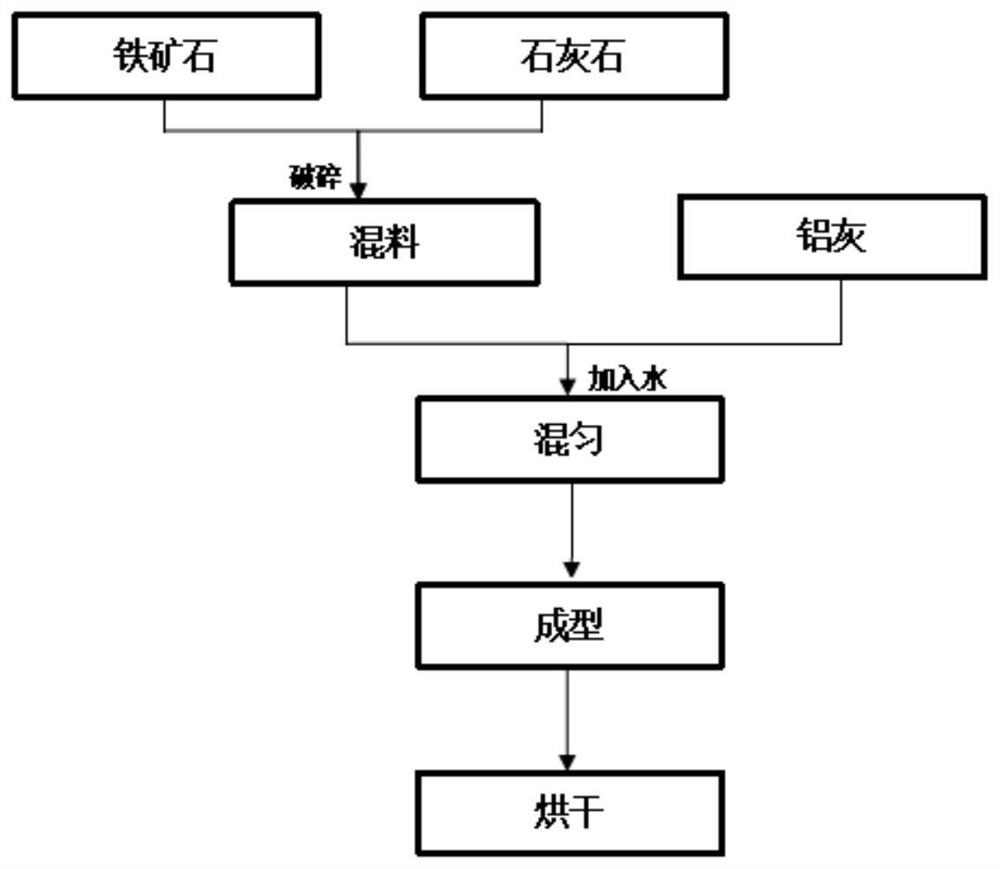

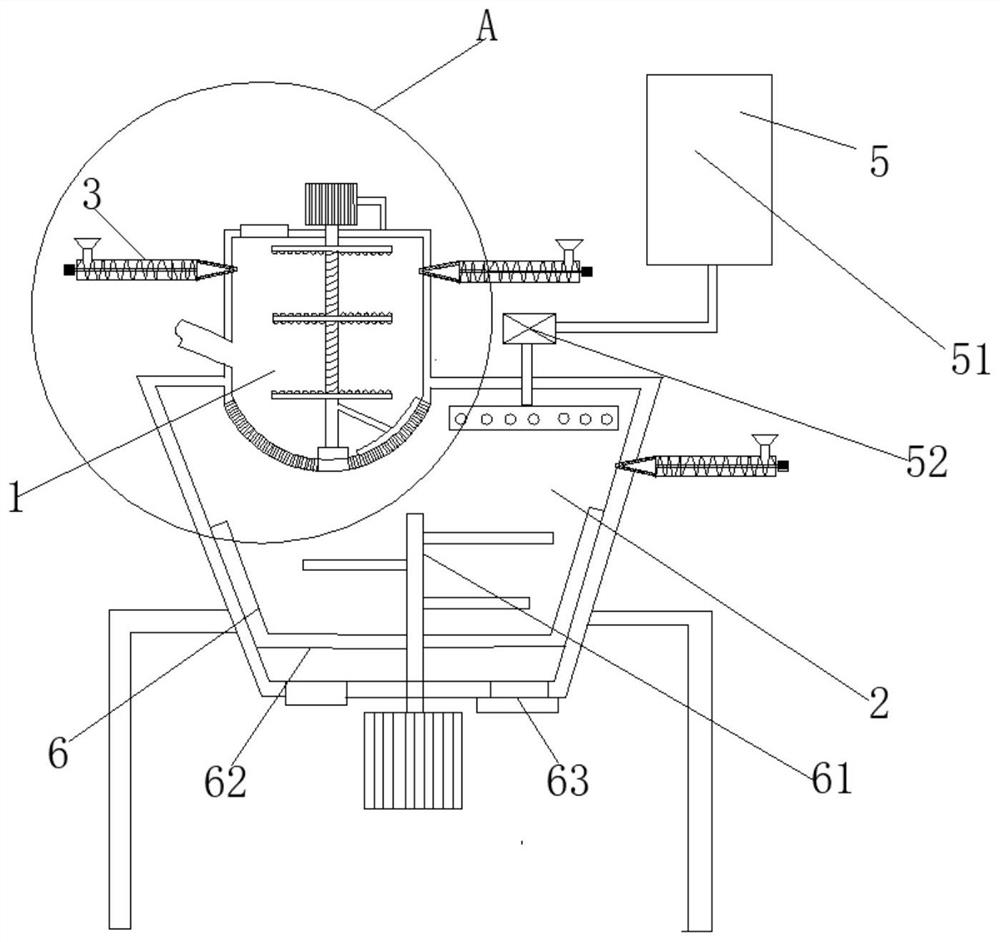

[0051] A preparation method of a low-cost composite high-efficiency exothermic agent for a converter, the specific steps of which are as follows:

[0052] S1: Weigh aluminum ash with a weight ratio of 20% to 50%, iron ore with a weight ratio of 40% to 60%, and limestone with a weight ratio of 10% to 20%;

[0053] S2: The iron ore and limestone weighed in step S1 are crushed and ground into powder particles by a grinding and mixing machine. However, its weight ratio shall not exceed 5-10% of the total weight of the powder particles;

[0054] S3: Add the aluminum ash and water weighed in step S1 to the powder particles of iron ore and limestone after crushing and grinding in step S2 in the grinding and mixing machine, mix and stir to be mixed raw materials, the added water accounts for aluminum 8% to 12% of the total weight of ash, iron ore and limestone;

[0055] S4: The mixed raw materials in step S3 are pelletized or briqueted into raw heat-generating agent pellets, and the...

Embodiment 1

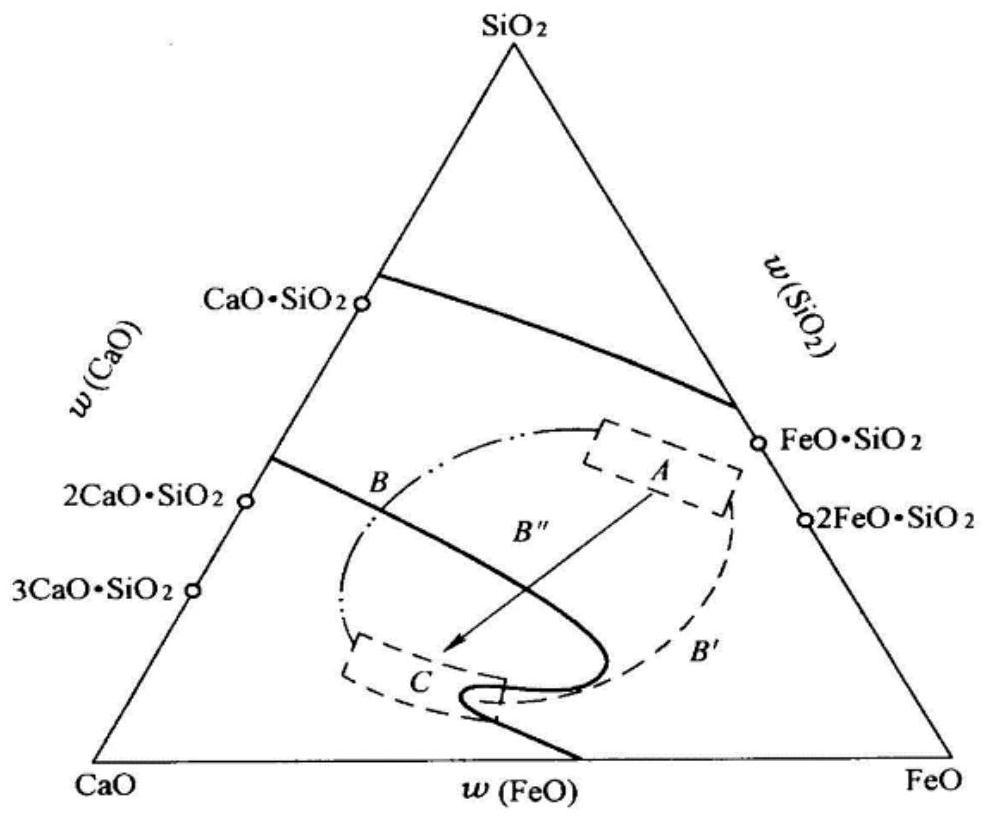

[0063] Aluminum ash, iron ore and limestone are used to prepare a low-cost composite high-efficiency exothermic agent for converters, wherein the weight percent of aluminum ash is 20%, the weight percent of iron ore is 60%, and the weight percent of limestone is 20%.

[0064] The chemical composition and mass percentage of aluminum ash are: w(Al) is 19.86%, w(Al) 2 O 3 ) is 47.24%, and the rest is SiO 2 , CaO, MgO, FeO, MnO, Na 2 O and inevitable impurities. According to the preparation method of the present invention, the above-mentioned raw materials are ground, mixed, shaped and dried to prepare the exothermic agent.

Embodiment 2

[0066] Aluminum ash, iron ore and limestone are used to prepare low-cost composite high-efficiency exothermic agent for converter, wherein the weight percent of aluminum ash is 30%, the weight percent of iron ore is 53%, and the weight percent of limestone is 17%.

[0067] The chemical composition and mass percentage of aluminum ash are: w(Al) is 19.86%, w(Al) 2 O 3 ) is 47.24%, and the rest is SiO 2 , CaO, MgO, FeO, MnO, Na 2 O and inevitable impurities. According to the preparation method of the present invention, the above-mentioned raw materials are ground, mixed, shaped and dried to prepare the exothermic agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com