Single gas cell solid oxide fuel cell of electrolyte-supporting type

A technology of solid oxide and fuel cells, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc. It can solve the problems of poor battery output performance and large electrolyte ohmic impedance, so as to improve output performance and reduce ohmic resistance. Impedance, the effect of enlarging the path area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

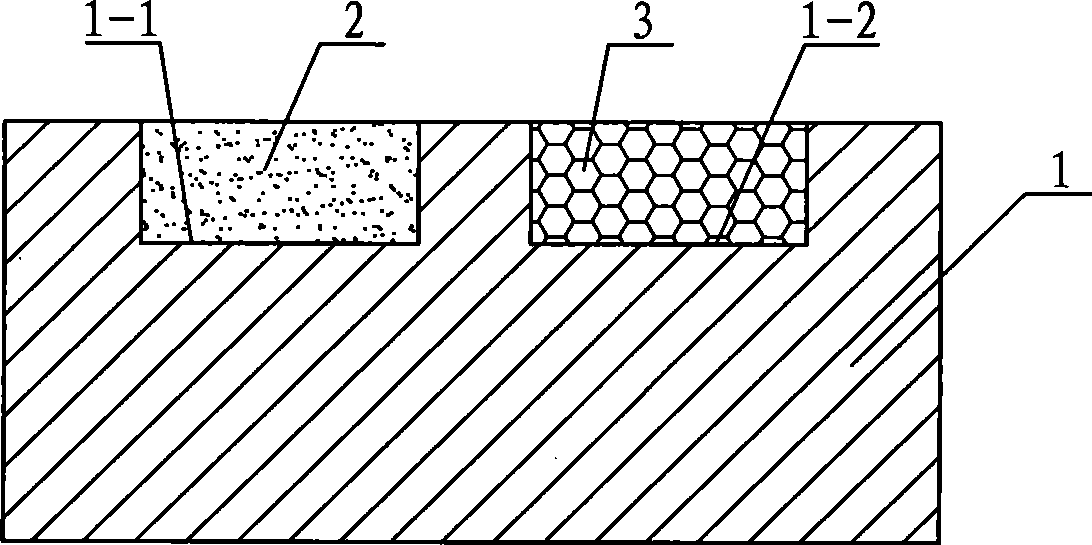

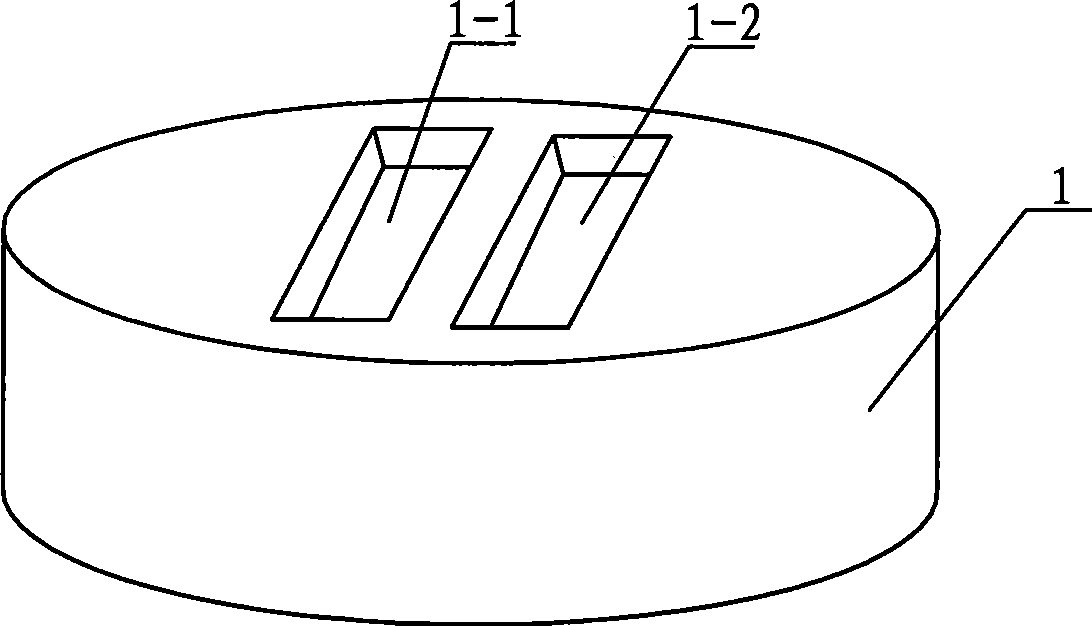

[0008] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is described. This embodiment is composed of a first electrolyte support 1, an anode slurry 2 and a cathode slurry 3. The surface of the first electrolyte support 1 is provided with at least one anode groove 1-1 and at least one The cathode groove 1-2, the anode groove 1-1 is coated with the anode slurry 2, and the cathode groove 1-2 is coated with the cathode slurry 3. The anode groove 1-1 and the cathode groove 1-2 make the anode slurry 2 and the cathode slurry 3 flow along the groove wall, and the groove wall expands the current flow path and reduces the ohmic impedance of the electrolyte. The realization process of the present invention is as follows: 1. Design the mold according to the external shape of the first electrolyte support body 1, put the electrolyte powder into the mold, and press the electrolyte powder into a green body under a pressure of 10-2000Mpa; 2. Use a carving knif...

specific Embodiment approach 2

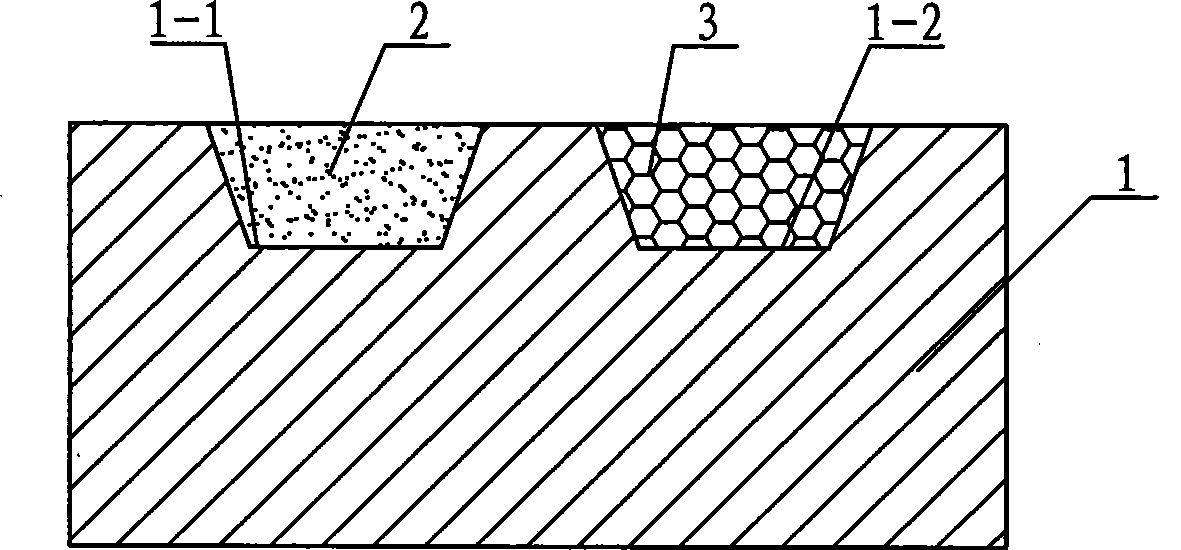

[0009] Specific implementation mode two: combination figure 1 , image 3 and Figure 4 To illustrate this embodiment, the cross-sections of the anode groove 1-1 and the cathode groove 1-2 on the first electrolyte support body 1 of this embodiment are square, trapezoidal or arc-shaped. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 , image 3 , Figure 4 and Figure 5 To illustrate this embodiment, the longitudinal section of the first electrolyte support 1 in this embodiment is square, rectangular or circular, and the longitudinal section of the first electrolyte support 1 is the same as the anode groove 1-1 or the cathode groove 1 -2 Sections with consistent cross-sectional orientation. This design can meet the needs of batteries with different structures. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com