A porous separation membrane for zinc-bromine flow battery and its preparation method

A technology of zinc-bromine flow battery and porous separation membrane, which is applied in the field of separation membrane, can solve the problems of increasing the mass transfer resistance of the separation membrane, fatigue or damage of the membrane matrix, and large mass transfer resistance, so as to reduce the difficulty of flow field planning, Reduce the effect of ohmic impedance and concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a porous separation membrane, comprising the steps of:

[0030] (1) Mix 9.8wt% polyethylene and polyvinyl acetate copolymer polyethylene film base material, 0.1wt% single-layer graphene conductive agent, 90wt% N-methylpyrrolidone solvent, and 0.1wt% polyvinylpyrrolidone dispersant , the slurry was obtained after stirring and grinding at 20°C;

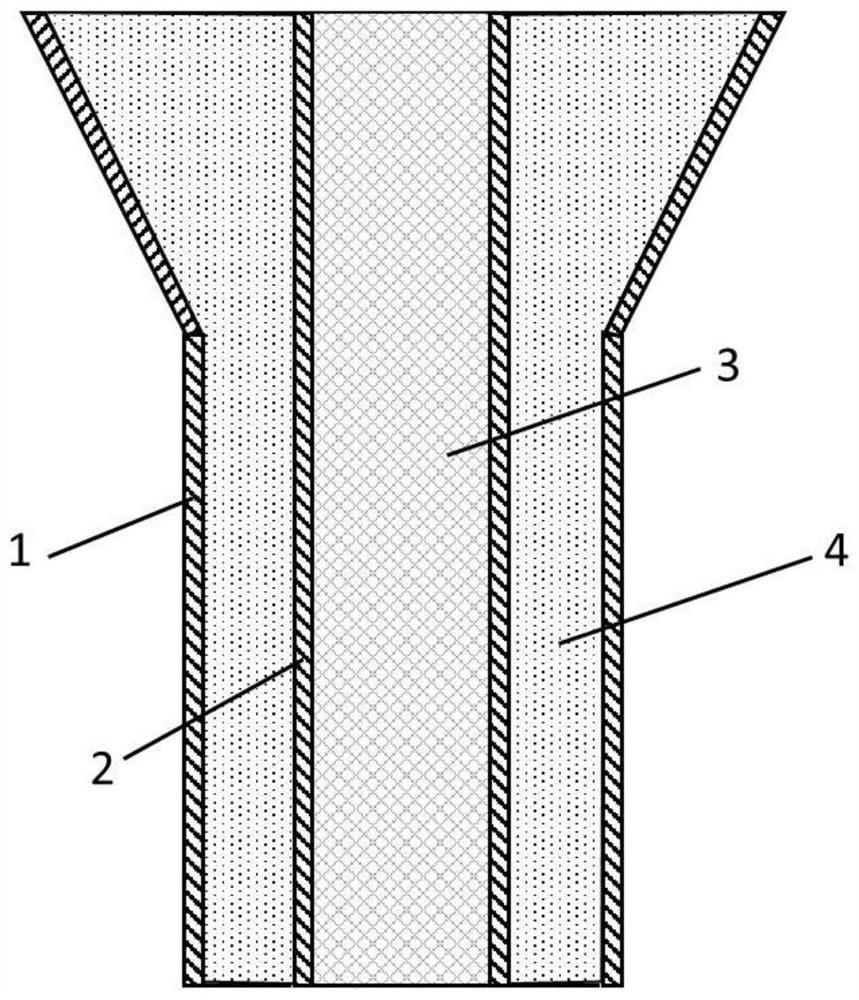

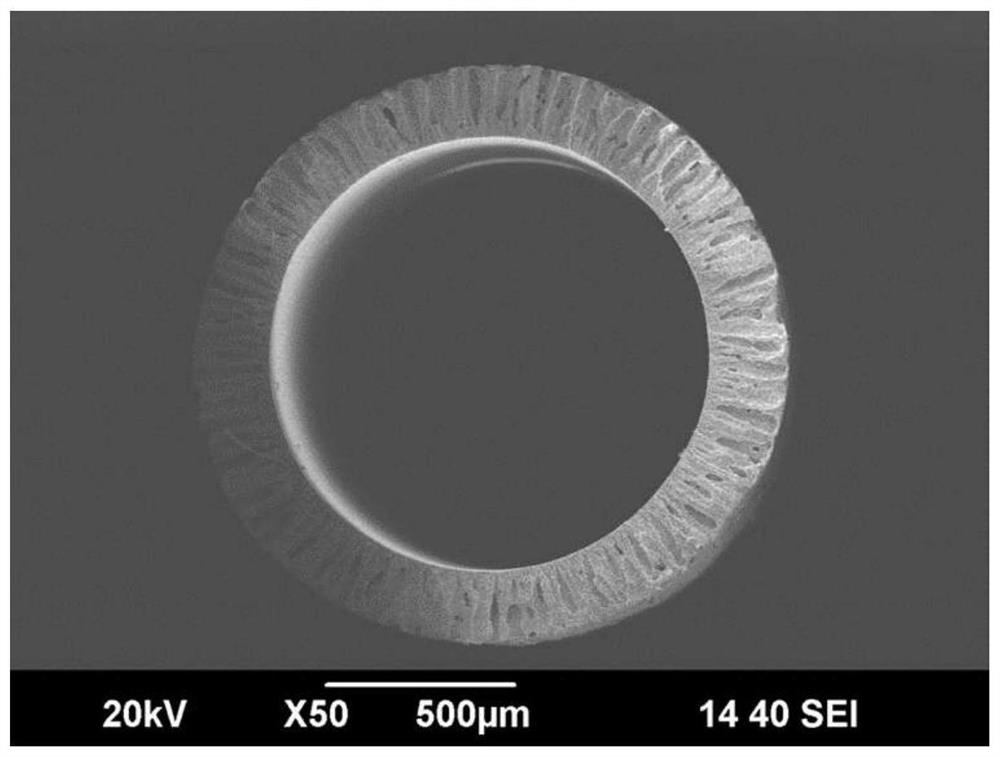

[0031] (2) Extrude the slurry through a spinneret with an outer diameter of inner tube 2 of 0.45 mm and an inner diameter of outer tube 1 of 0.5 mm, carry out phase inversion molding in water or ethanol, and solidify to obtain a porous separation membrane blank. The steps of conversion molding include: carry out at a temperature of 15°C and a relative humidity of 45%, through convective evaporation, after the solvent starts to volatilize, put it in a 19°C gel bath for 22 hours, and then put it in a 20°C ultra- In pure water, let it stand for 4 hours to remove a small amount of solvent and non-solvent addit...

Embodiment 2

[0037] A method for preparing a porous separation membrane, comprising the steps of:

[0038](1) Mix 60wt% polyvinyl acetate film matrix material, 18wt% multilayer graphene conductive agent, 20wt% dimethylformamide solvent, 2wt% aminotriacetic acid dispersant, stir and grind at 60°C to get slurry;

[0039] (2) Extrude the slurry through a spinneret with an outer diameter of inner tube 2 of 190 mm and an inner diameter of outer tube 1 of 200 mm, perform phase inversion molding in water or ethanol, solidify to obtain a porous separation membrane blank, and phase inversion molding The steps include: carry out at a temperature of 25°C and a relative humidity of 60%, through convective evaporation, after the solvent begins to volatilize, put it in a gel bath at 21°C for 28 hours, and then put it into ultrapure water at 30°C In, stand still for 8 hours, remove a small amount of solvent and non-solvent additive remaining in the film;

[0040] (3) Dry and cut the porous separation m...

Embodiment 3

[0043] A method for preparing a porous separation membrane, comprising the steps of:

[0044] (1) Mix 25wt% chlorosulfonated polyethylene film base material, 1 wt% acetylene black conductive agent, 73wt% dimethylacetamide solvent, 1 wt% ethylenediaminetetraacetic acid dispersant, stir and grind at 25°C get slurry;

[0045] (2) Extrude the slurry through a spinneret with an outer diameter of the inner tube 2 of 1.42 mm and an inner diameter of the outer tube 1 of 1.5 mm, perform phase inversion molding in water or ethanol, and solidify to obtain a porous separation membrane body, which is relatively The steps of conversion molding include: carry out at a temperature of 20°C and a relative humidity of 53%, through convective evaporation, after the solvent starts to volatilize, put it in a 20°C gel bath for 25 hours, and then put it in a 25°C ultra- In pure water, let it stand for 6 hours to remove a small amount of solvent and non-solvent additives remaining in the film;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com