Die-cut tab cylindrical battery and manufacturing process thereof

A cylindrical battery and manufacturing process technology, which is applied in the direction of sustainable manufacturing/processing, hybrid/electric double layer capacitor manufacturing, secondary batteries, etc., can solve problems affecting battery power performance, and avoid welding slag and burrs, Effects of improving reliability and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Firstly, the slurry containing the positive active material and the negative active material is respectively coated on the aluminum foil and the copper foil current collector, and an uncoated area with a width of 20mm is reserved on both sides of the aluminum foil and the copper foil current collector.

[0036] (2) Use a cutting machine to cut the aluminum foil and copper foil current collector coated with the active material into a suitable width.

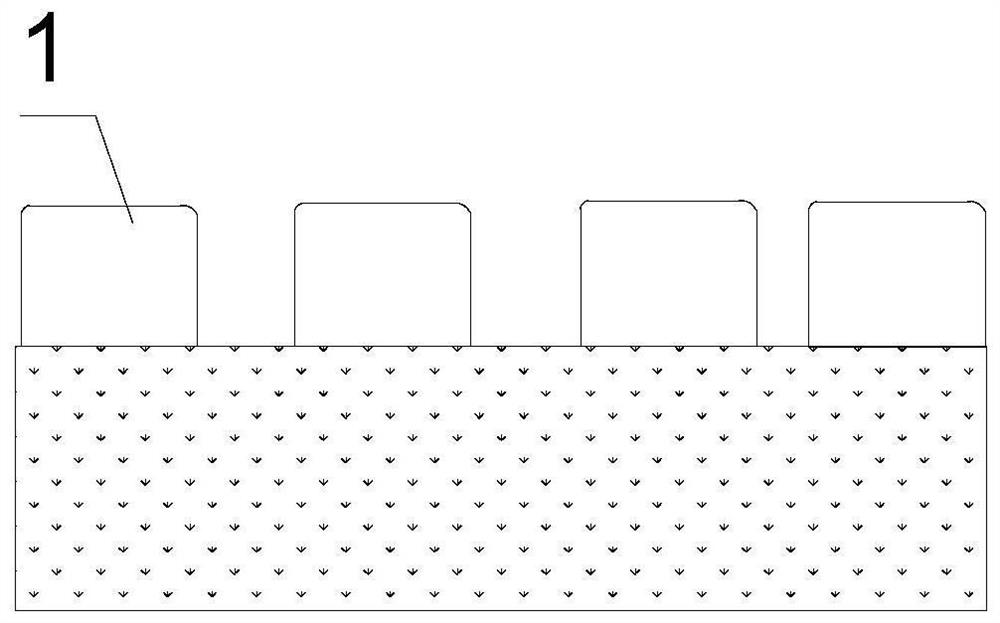

[0037] (3) Use a laser die-cutting machine to cut the uncoated area reserved for the aluminum foil and copper foil collector according to the predetermined procedure and at a certain interval into the following figure 1 structure shown.

[0038] (4) A winding machine is used to wind the positive and negative pole pieces and the diaphragm after die-cutting the tab 1 to form a battery cell, and the wound tabs of the battery core present a circular distribution.

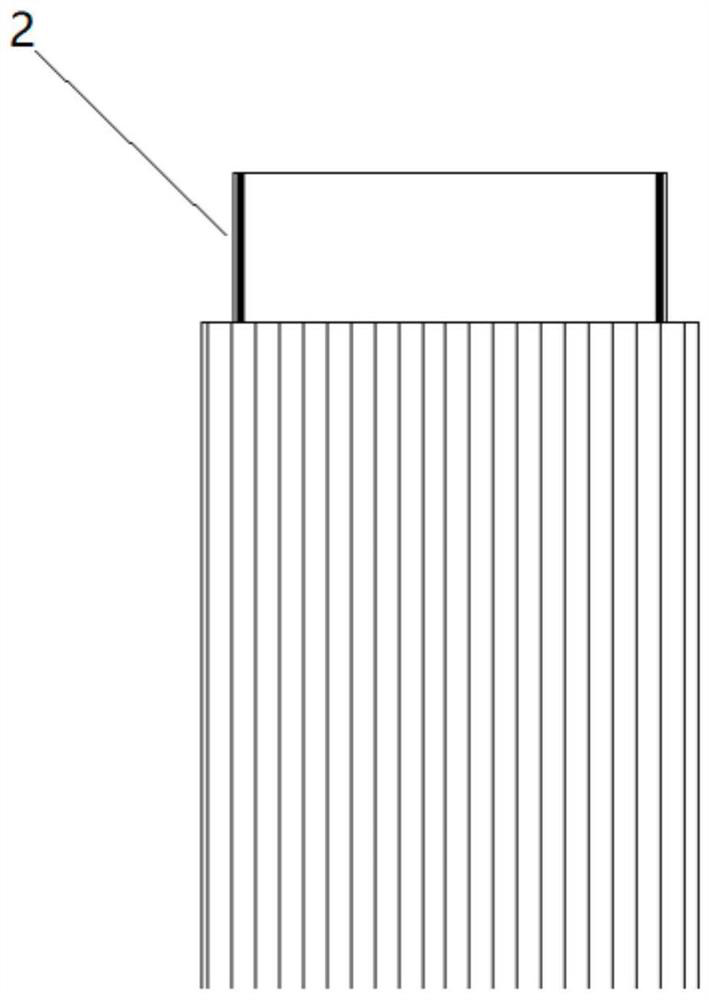

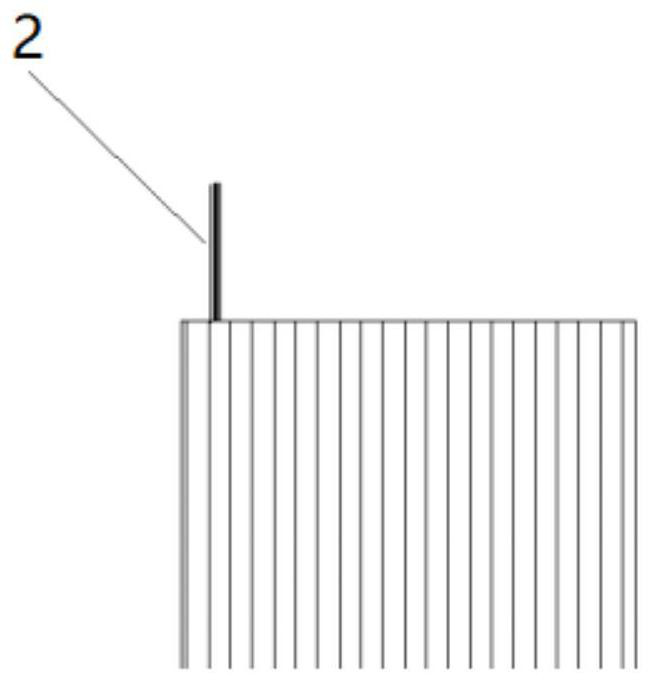

[0039] (5) Use special plastic tooling to shape the tab 2 ...

Embodiment 2

[0043] (1) Firstly, the slurry containing the positive active material and the negative active material is respectively coated on the aluminum foil and the copper foil current collector, and an uncoated area with a width of 30mm is reserved on both sides of the aluminum foil and the copper foil current collector.

[0044] (2) Use a cutting machine to cut the aluminum foil and copper foil current collector coated with the active material into a suitable width.

[0045] (3) Use a laser die-cutting machine to cut the uncoated area reserved for the aluminum foil and copper foil current collector into the following according to the predetermined program and a certain interval width. figure 1 structure shown.

[0046] (4) Use a winding machine to wind the positive and negative pole pieces and diaphragm after die-cutting the tabs into a battery cell, and the tabs of the battery core should be distributed in a straight line.

[0047] (5) Use special plastic tooling to shape the tabs ...

Embodiment 3

[0051] (1) Firstly, the slurry containing the positive active material and the negative active material is respectively coated on the aluminum foil and the copper foil current collector, and an uncoated area with a width of 30mm is reserved on both sides of the aluminum foil and the copper foil current collector.

[0052] (2) Use a slitter to cut the aluminum foil coated with the active material and the aluminum foil current collector into appropriate widths.

[0053] (3) Use a laser die-cutting machine to cut the uncoated area reserved for the aluminum foil and copper foil current collector into the following according to the predetermined program and a certain interval width. figure 1 structure shown.

[0054] (4) Use a winding machine to wind the positive and negative pole pieces and diaphragm after die-cutting the tabs into a battery cell, and the tabs of the battery core should be distributed in a straight line.

[0055] (5) Use special plastic tooling to shape the tabs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com