Maleic anhydride graft polybutylene succinate (PBS) alloy and preparation method thereof

A technology of polybutylene succinate and polybutylene succinate, which is applied in the field of degradable materials and its manufacturing, can solve the problem of low melt strength, low physical and mechanical properties of molded products, and direct blending of two phases Poor capacity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Get 100 parts of polybutylene succinate by weight, 20 parts of polylactic acid resin, 1.0 part of maleic anhydride, 0.02 part of initiator, 0.4 part of acetone;

[0038] Pass polybutylene succinate and polylactic acid resin through a vacuum drying tank to remove surface moisture;

[0039] Add polybutylene succinate, polylactic acid resin, maleic anhydride, initiator and acetone into the mixer and mix;

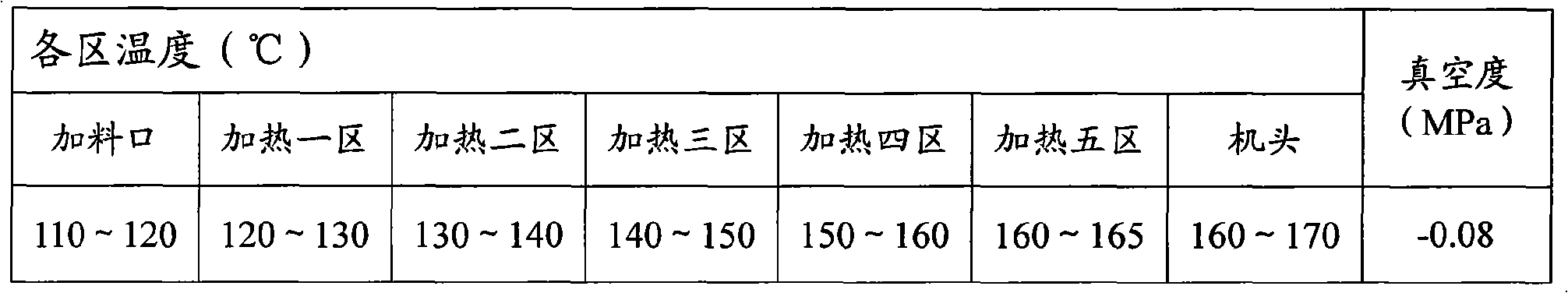

[0040] According to the conditions of the twin-screw reaction extruder set above, the mixed materials are put into the twin-screw reaction extruder to carry out reaction grafting, traction, underwater drawing, and granulation.

Embodiment 2

[0042] Take 100 parts of polybutylene succinate, 20 parts of polylactic acid resin, 2.0 parts of maleic anhydride, 0.05 parts of initiator and 1.0 part of acetone by weight.

[0043] Other steps are the same as in Example 1.

Embodiment 3

[0045] Take 100 parts of polybutylene succinate, 30 parts of polylactic acid resin, 1.0 part of maleic anhydride, 0.02 part of initiator and 0.4 part of acetone by weight.

[0046] Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com