Dipper tooth material

A shovel tooth, weight percentage technology, applied in the field of shovel tooth materials, can solve problems such as insufficient strength of shovel tooth section, inability of shovel tooth materials to meet the use requirements in terms of strength and toughness, and too steep hardness gradient, so as to meet market needs and improve The effect of improving the technical quality level of the product, the comprehensive mechanical properties of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

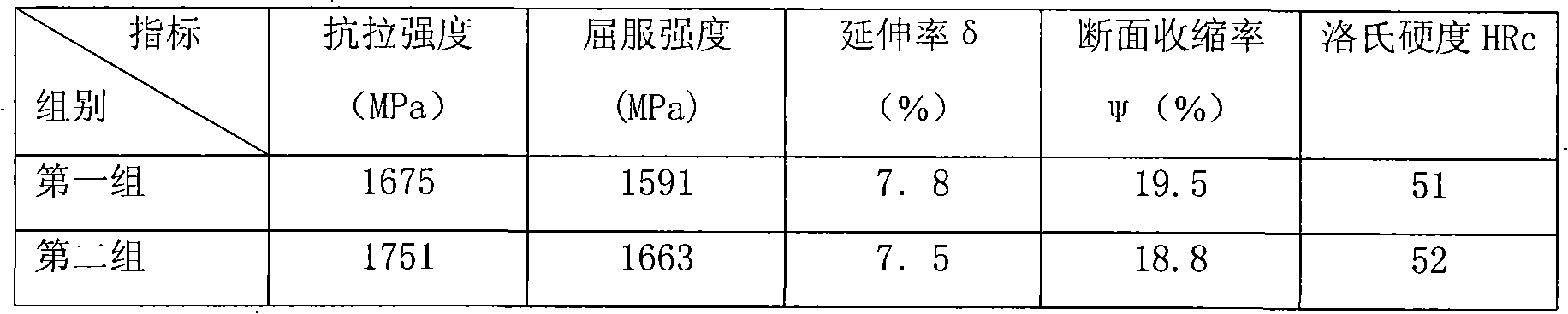

Examples

Embodiment

[0023] Embodiment of the present invention shovel tooth material sample preparation process is as follows:

[0024] Add each component material of the present invention into a 500kg thyristor intermediate frequency induction furnace→

[0025] Melting the above materials (temperature 1650-1670°C) → deoxidation, slag removal → component analysis → adding alloy elements to adjust the composition → deoxidation, slag removal → composition test (fine-tuning of composition) → casting (casting molten steel temperature 1560-1620°C), Cast a wedge-shaped test block and 6 pieces of 40kg / piece shovel teeth.

[0026] Then carry out heat treatment on the shovel tooth workpiece and the wedge-shaped test block: use Rx3-45-9 box-type electric furnace for normalizing and quenching treatment, and then use RJ2-55-6 well-type electric furnace for tempering treatment.

[0027] The above preparation process is generally the same as the production of conventional shovel tooth material samples in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com