Double-needle bed raschel type warp knitting machine

A double-needle bed and knitting machine technology, applied to flat warp knitting machines, warp knitting, knitting, etc., can solve problems such as large designs, and achieve the effect of compact construction and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

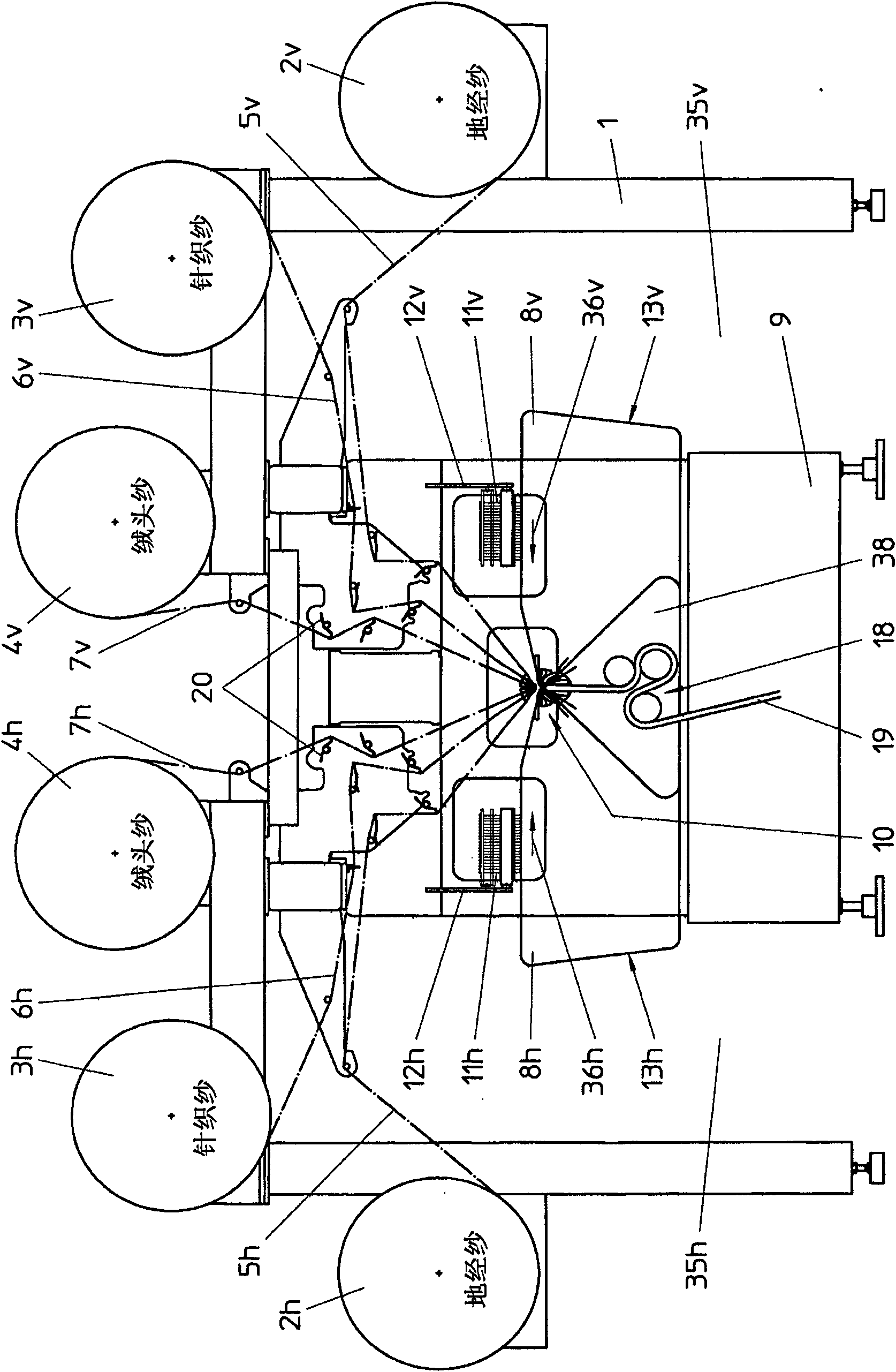

[0027] figure 1 A side view of a double-needle-bar Raschel machine according to the invention is shown, hereinafter referred to simply as a Raschel machine. The view is externally delimited by the warp beam suspension bracket 1 , which surrounds the associated warp knitting machine 9 from three sides. Two ground warp yarn shafts 2h, v, two knitting yarn shafts 3h, v and two pile yarn shafts 4h, v are respectively arranged on the warp beam suspension bracket. The additional letters h and v here and below stand for parts of identical or mirror-image design, which are constructed symmetrically on the rear or front side of the warp knitting machine 9 . exist figure 1 Clearly recognizable are the two gaps 35h, v between the beam suspension bracket 1 and the warp knitting machine 9 . An operator can access the operating end of the warp knitting machine 9 through such gaps 35h, v.

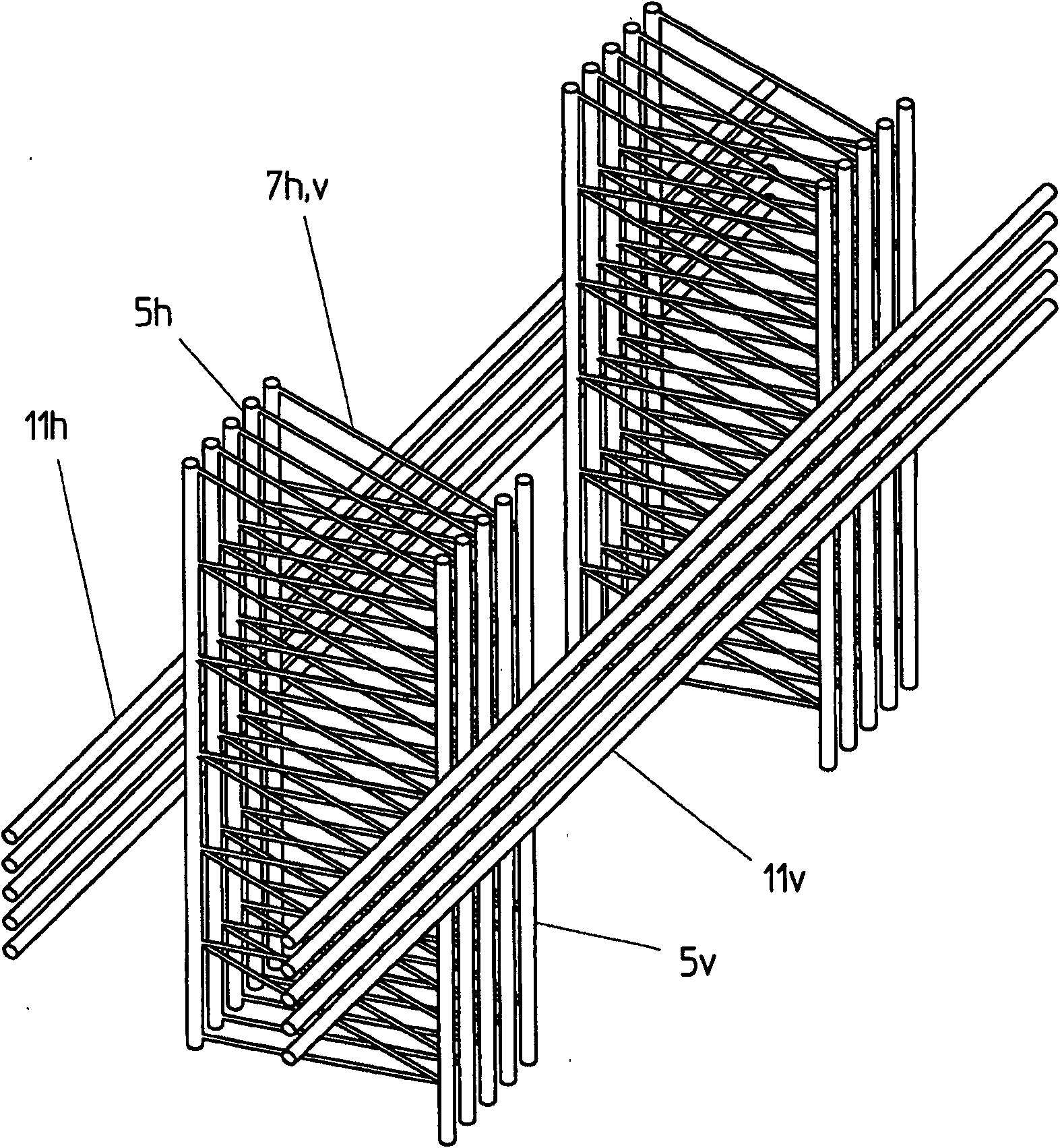

[0028] Ground warp yarns 5h, v, knitting yarns 6h, v and pile yarns 7h, v are sent to knitting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com