Method and device for evenly distributing fluid medium

A technology of uniform distribution and fluid medium, applied in the direction of washing/replacing pulp treatment liquid, etc., can solve the problems of clogging of the pulp separation port, adverse effects, increase the amount of washing liquid, etc., to prevent flocculation, reduce dosage, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: A method for evenly distributing a fluid medium, wherein the medium passes through a vertically arranged liquid inlet unit and a speed-increasing turbulent flow unit, and the medium flows to the lateral direction in the speed-up turbulent flow unit by first increasing speed and then entering a turbulent flow state The distribution unit makes the medium evenly distributed and flows smoothly before entering the dehydration carrier.

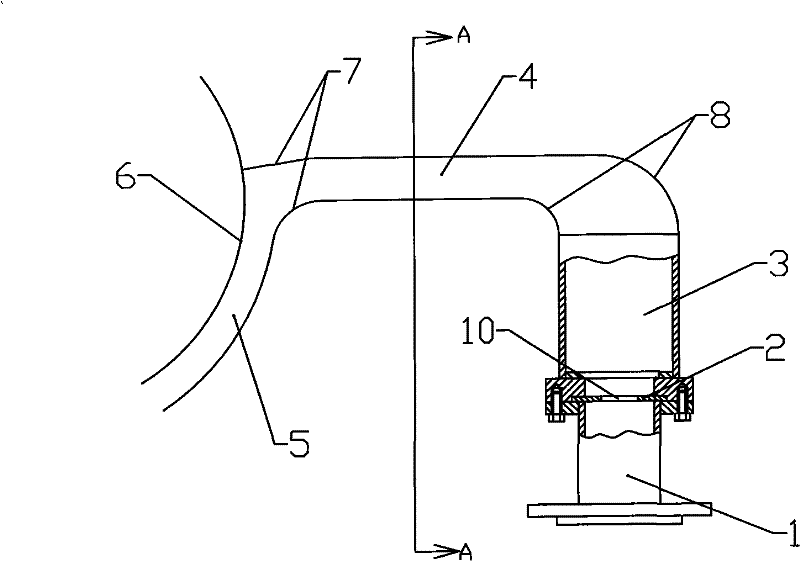

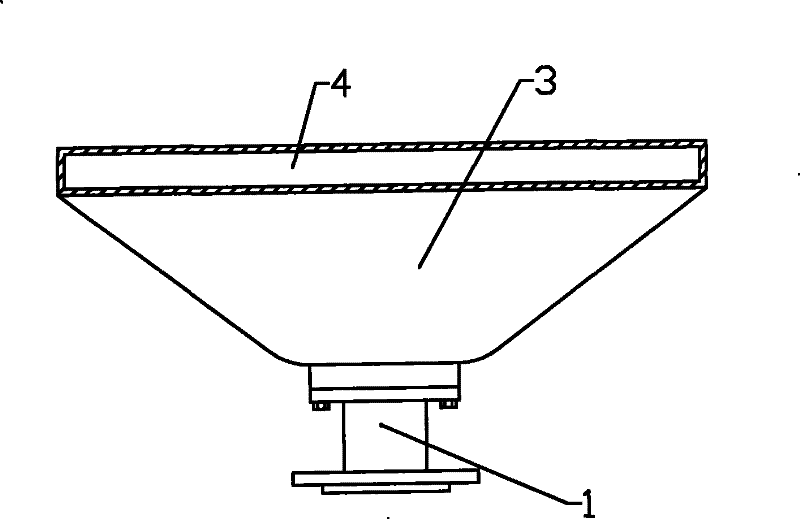

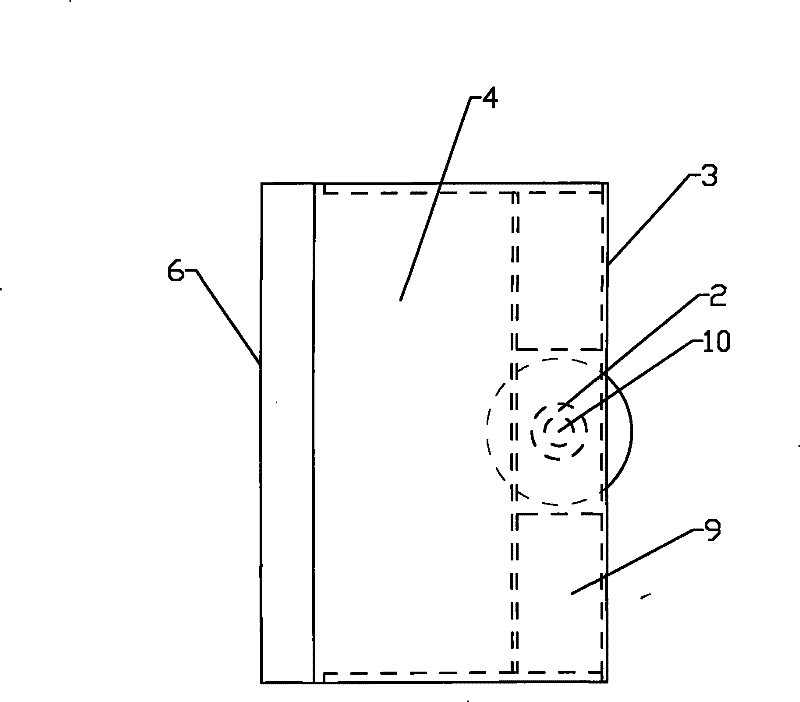

[0029] A device for uniform distribution of fluid medium, such as attached figure 1 , attached figure 2 As shown, the device includes a liquid inlet unit, a speed-increasing turbulent flow unit and a lateral distribution unit. The outlet position of the lateral distribution unit is connected with a flow channel 5 extending to the inlet of the dehydration carrier 6. The liquid inlet unit includes a A feed pipe 1 for controlling flow and pressure, the speed-up turbulence unit includes a flat funnel-shaped turbulent flow forming bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com