Ammonia evaporation and buffering integrated device

An ammonia evaporation and liquid ammonia evaporator technology, which is applied to mechanical equipment, equipment discharged from pressure vessels, gas/liquid distribution and storage, etc., can solve the problems of inconvenient installation, large space occupation, and re-condensation, etc. To achieve the effect of simple overall structure, avoiding re-condensation and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

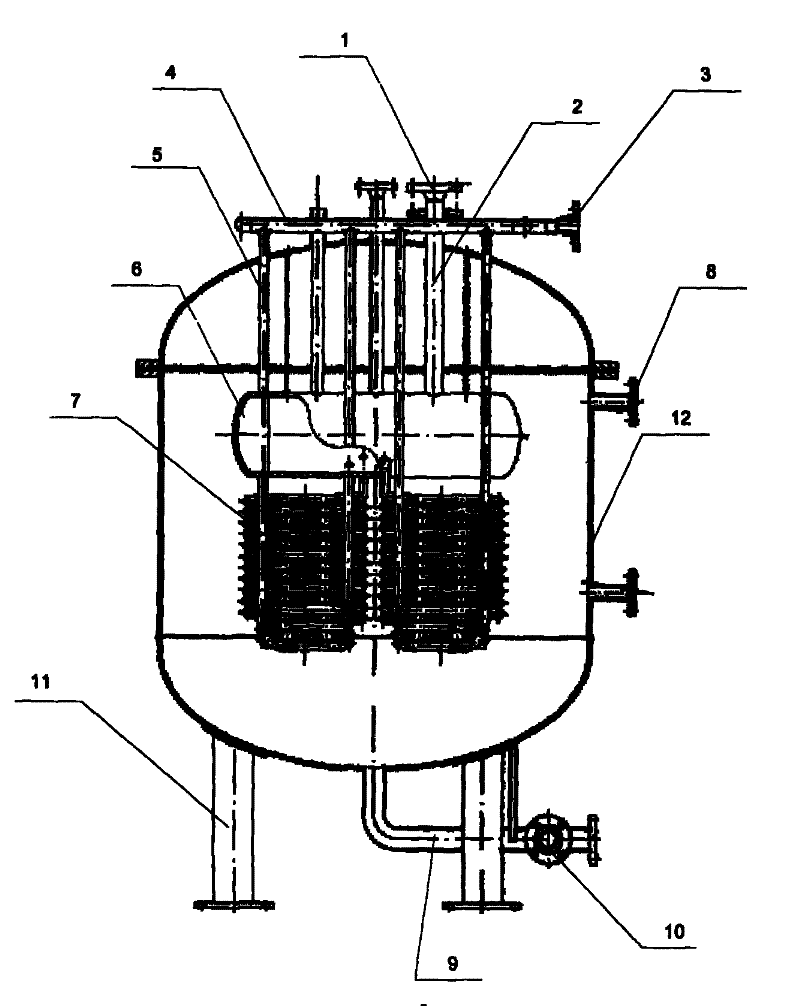

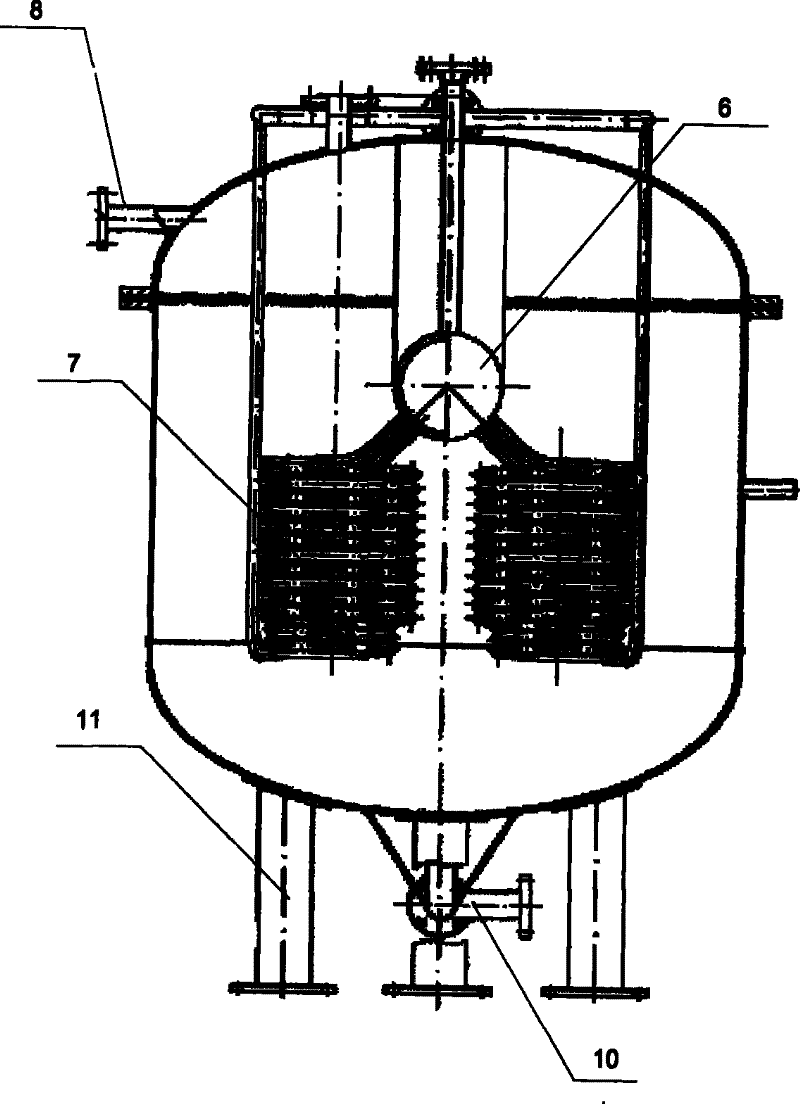

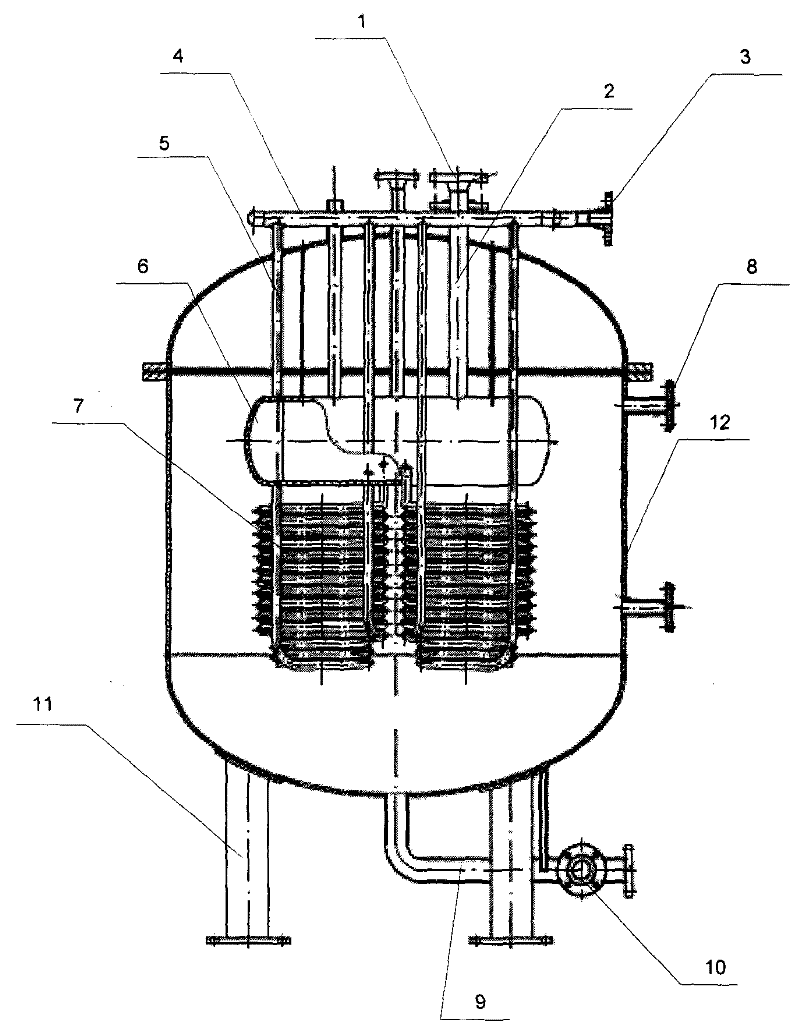

[0016] see figure 1 and figure 2 , the present invention provides a kind of integrated ammonia evaporation and buffering equipment, comprising a tank body 12, liquid ammonia enters the liquid ammonia main pipe 4 from the liquid ammonia input interface 3, and then enters several liquid ammonia branch pipes 5 communicating with the liquid ammonia main pipe, and then Enter the helical liquid ammonia evaporator 7 connected with the liquid ammonia branch pipe;

[0017] The tank body is provided with a heat medium inlet connected to the inner cavity of the tank, and a valve 8 connected to the heat medium inlet is provided to fill the inside of the tank with hot water or hot steam. Need temperature. An electric heater can also be installed in the tank, and the electric heater can be used to heat to ensure the required temperature in the tank.

[0018] The liquid ammonia in the liquid ammonia evaporator absorbs heat through heat exchange and vaporizes into ammonia gas, and the amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com