A kind of cationic rosin rubber emulsifier and preparation method thereof

A cationic rosin gum and emulsifier technology, applied in chemical instruments and methods, rosin addition, water repellent addition, etc., can solve the problems of lack of non-ionic emulsifier, weak system synergy, unstable system, etc., and achieve surface activity High, lower system free energy, lower production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

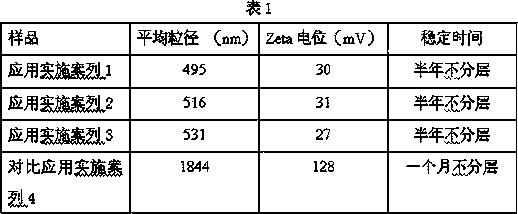

Examples

preparation example Construction

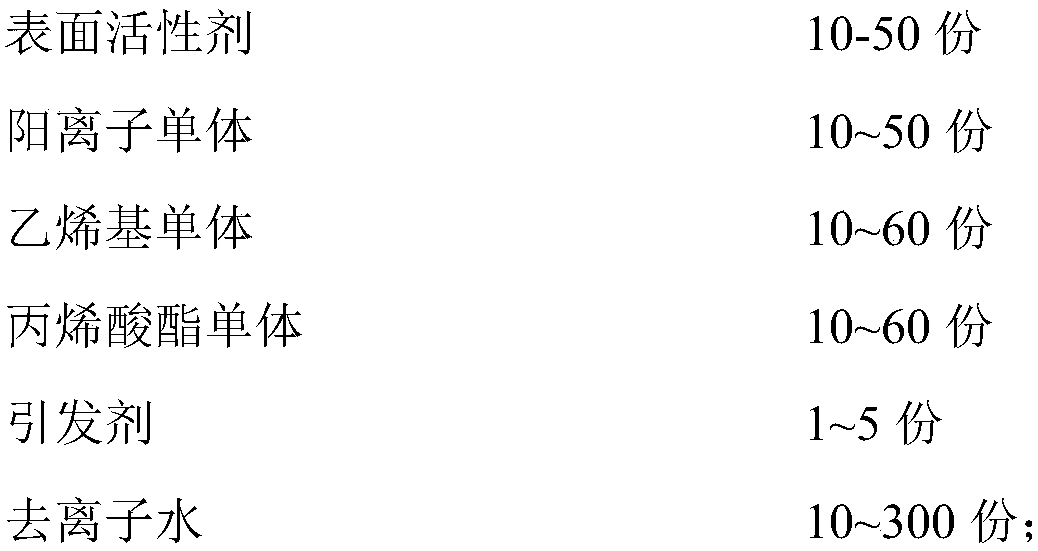

[0031] The invention provides a kind of preparation method of cationic rosin emulsifier, comprising the following steps:

[0032] Step 1, using a cationic monomer to prepare a cationic monomer solution;

[0033] Step 2, prepare monomer solution: mix vinyl monomer and acrylate monomer in proportion;

[0034] Step 3, preparing initiator solution: the initiator concentration is 1%;

[0035] Step 4, adding the surfactant into the reactor, then adding deionized water, and raising the temperature;

[0036] Step 5, when the temperature in the kettle is 60°C, add cationic monomer solution, monomer solution and initiator solution at one time, continue to heat up and control the temperature at 80±2°C, and keep it warm for 3 hours;

[0037] Step 6: After the heat preservation is completed, the temperature in the kettle is raised to 100°C, the deionized water is evaporated, and the solid content is adjusted to 35% to obtain the cationic rosin rubber emulsifier.

preparation Embodiment 1

[0040] Add 15g of surfactant OP-10 to the bottom of the kettle, add 300g of water, raise the temperature, and prepare cationic monomer solution (20g diallyldimethylammonium chloride + 50g water), monomer solution (methyl methacrylate 15g + vinylpyrrolidone 20g), initiator sodium persulfate solution (1.6g + 30g water), when the temperature in the kettle is 60°C, add cationic monomer, monomer solution and initiator solution at one time, and control the temperature at 80°C Nearby, keep warm for 3 hours, and then distill deionized water to a solid content of about 35% to obtain a cationic rosin rubber emulsifier.

preparation Embodiment 2

[0042] Add 15g of surface active OP-10 agent to the bottom of the kettle, add 300g of water, raise the temperature, prepare cationic monomer solution (20g acryloyloxyethyltrimethylammonium chloride + 50g water), monomer solution (butyl acrylate 15g+ Styrene 20g), initiator potassium persulfate solution (1.6g+30g water), when the temperature in the kettle is 60°C, add cationic monomer, monomer solution and initiator solution at one time, the temperature is controlled around 80°C, Keep warm for 3 hours, heat up and distill deionized water to a solid content of about 35% to obtain a cationic rosin rubber emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com