Cumulate molecular beam source for organic thin film

An organic thin film and molecular beam technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as substrate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

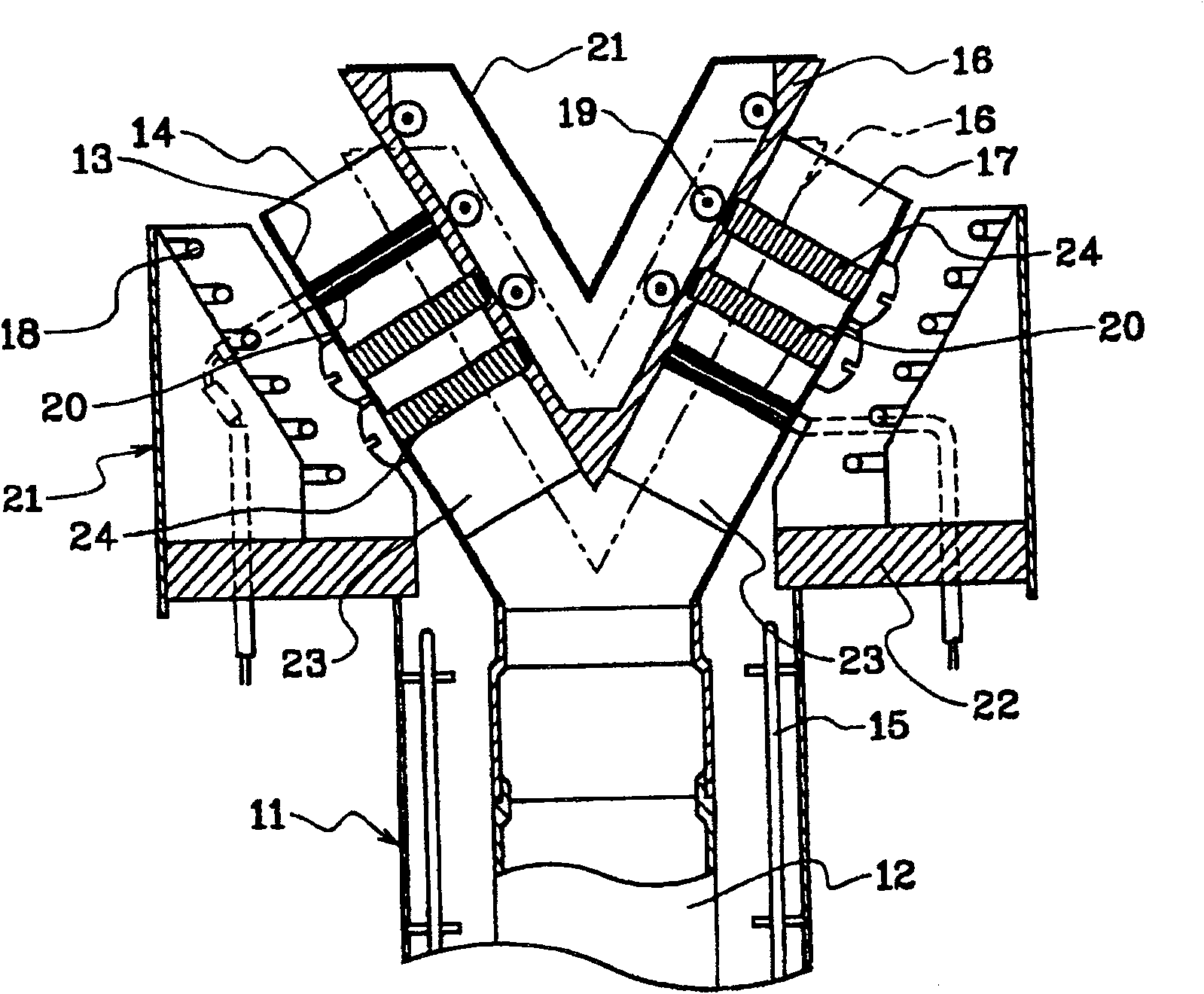

[0026] According to the invention, a valve is arranged on the route of the vapour, thereby making it possible to shut off the released vapour. Also, the heater is provided at the side of the molecule release opening where vapor is easy to condense or solidify; thereby preventing separation or deposition of evaporated material near the molecule release opening.

[0027] Hereinafter, embodiments according to the present invention will be fully explained with reference to the accompanying drawings.

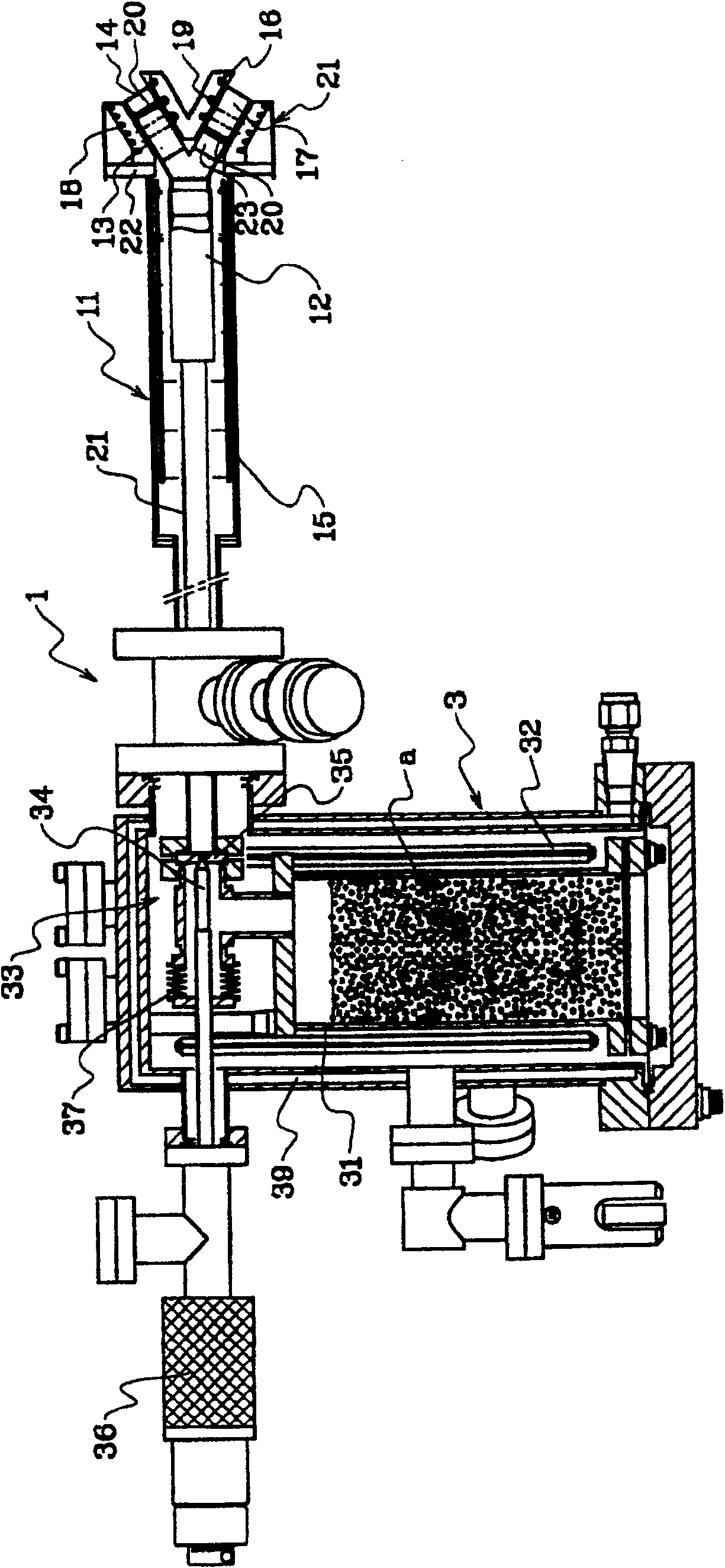

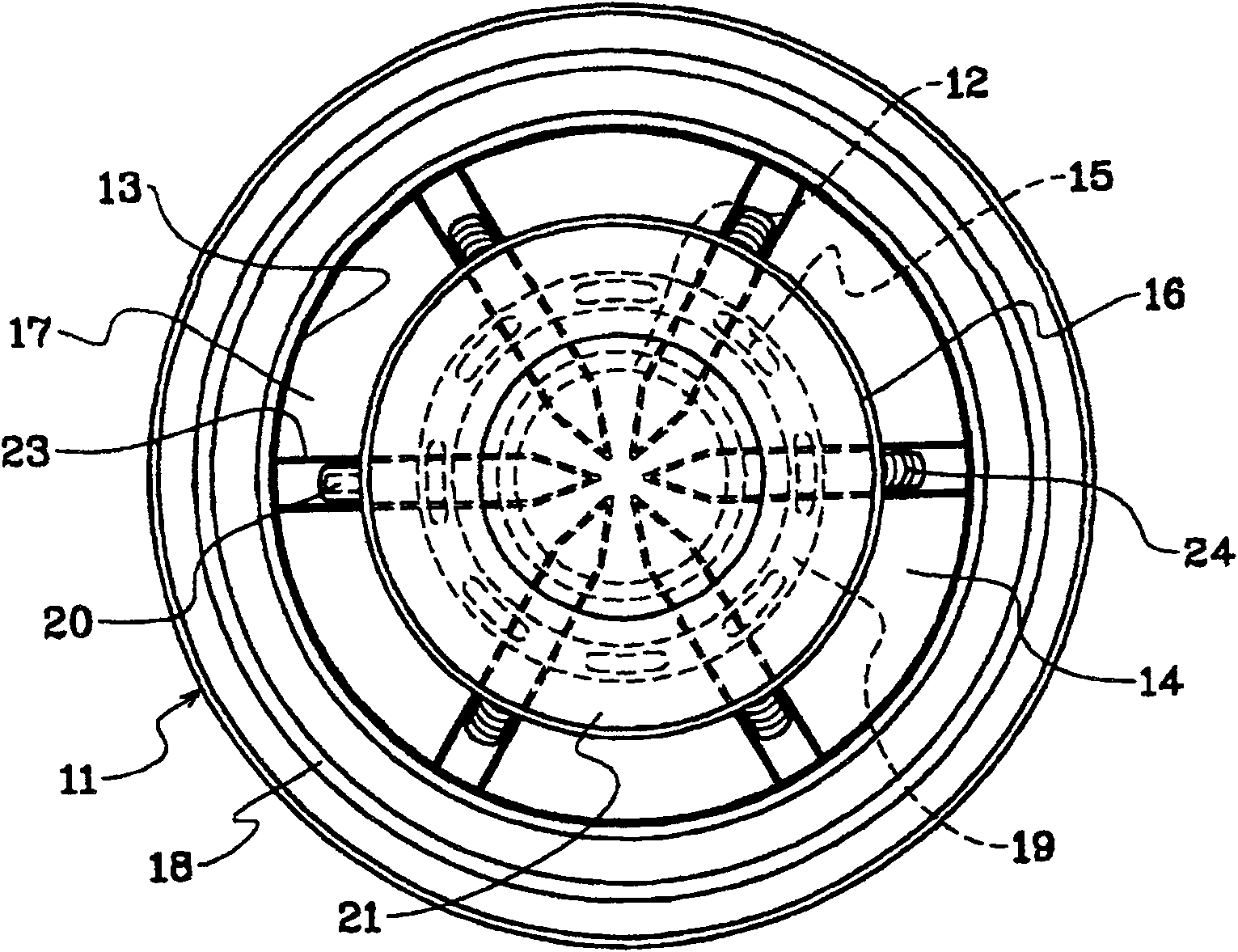

[0028] figure 1 A molecular beam source emission region 1 of material "a" formed by sublimation or evaporation of an emission film is shown.

[0029] The heating material accommodating part 3 of the molecular beam source emitting area 1 has a cylindrical vapor generating source 31 made of metal such as SUS or the like, that is, a material having high thermal conductivity, and the heating material "a" to be heated is accommodated in the crucible 31 . Such as Figure 6 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com