Calibration method of linear structured light three-dimensional visual sensor based on measuring blocks

A visual sensor and calibration method technology, applied in the field of visual measurement, can solve the problems of poor machining accuracy and cost, low coordinate accuracy of calibration points, and small number of extracted feature points, etc., to achieve low cost and high precision , good cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

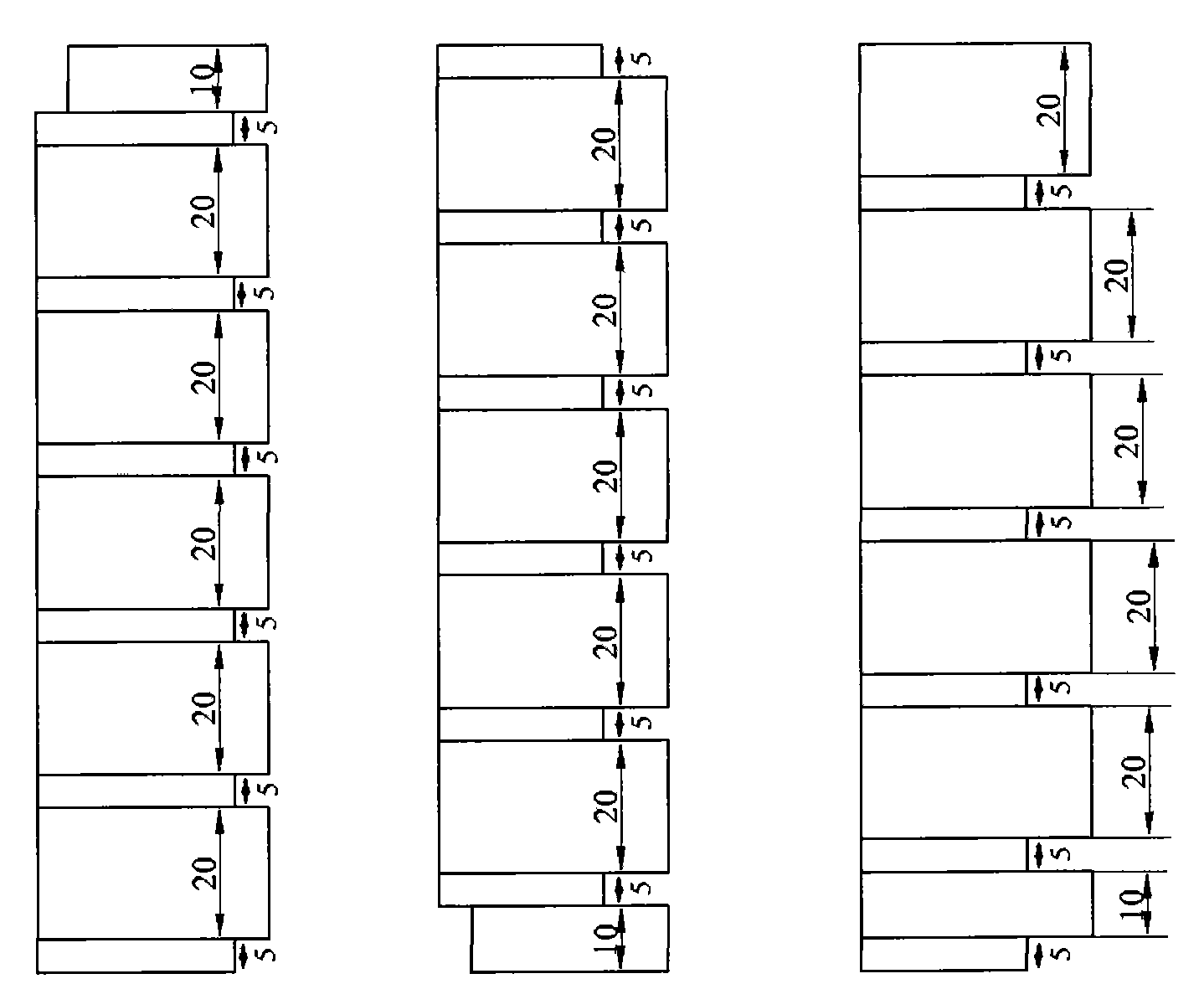

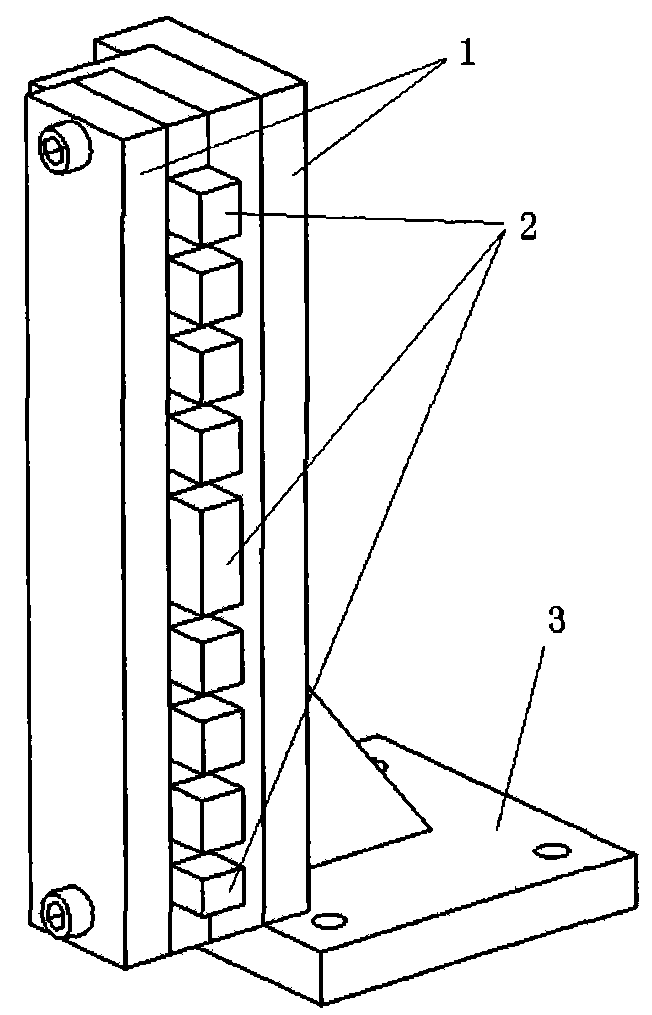

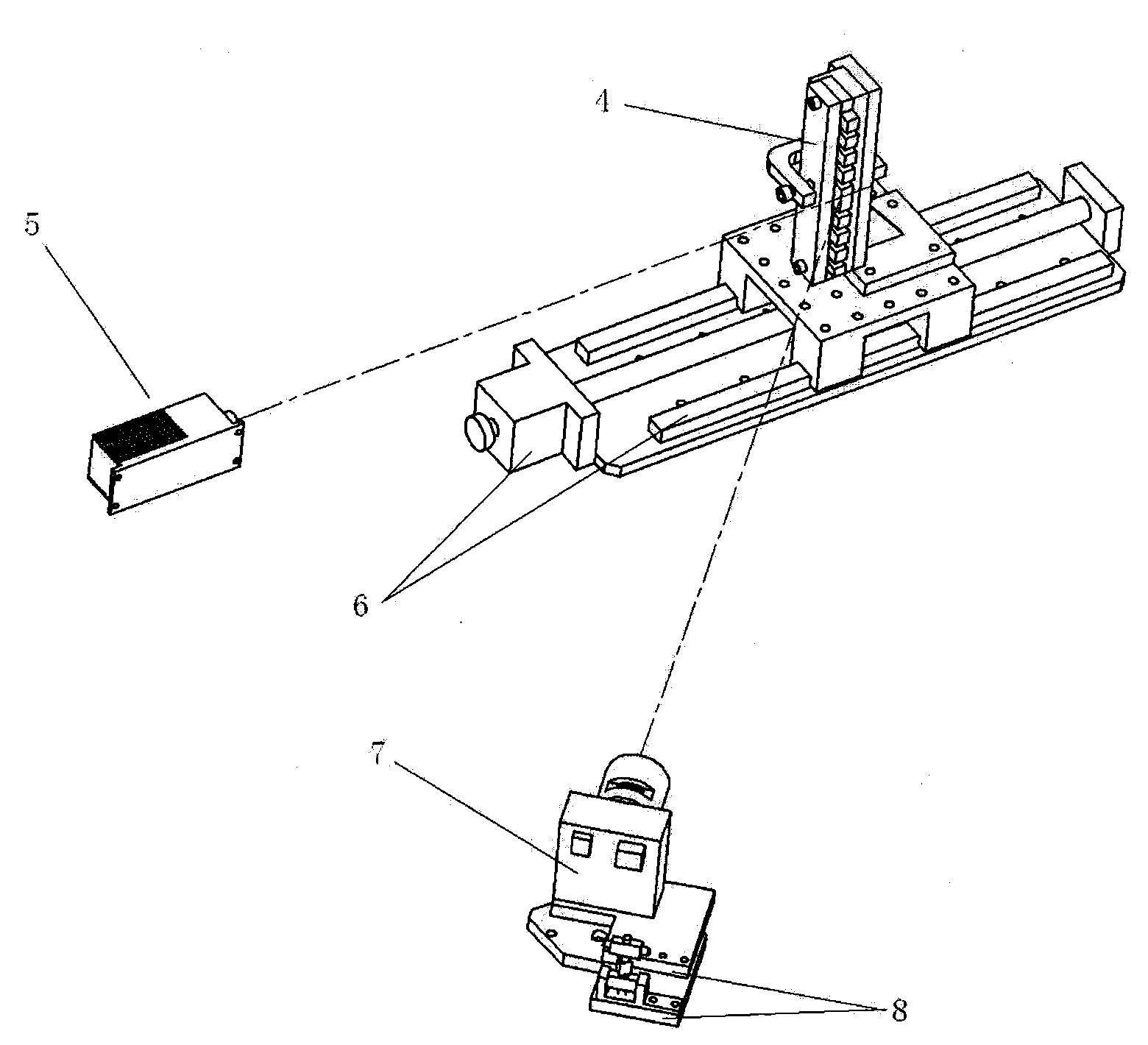

[0031] Embodiment: The calibration method of the structured light vision sensor based on the gauge block of the present invention can acquire multiple light stripe points at different positions under the condition of moving the gauge block target, and the number of light stripe points is determined by the size of the gauge block, namely The smaller the size of the gauge block within the fixed field of view, the more light bar points. The coordinate data of the end points of the light bar at all positions are obtained through image processing, and then calculated according to the relevant mathematical model to obtain the sensor parameters.

[0032] The method for calibrating the structured light vision sensor based on the gauge block of the present invention will be further described in detail below through specific embodiments and accompanying drawings.

[0033] The calibration system of the present invention is composed of gauge blocks of different specifications, targets, la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com