Handheld grinding pan and use method thereof

A grinding disc and hand-held technology, applied in the field of hand-held grinding devices, can solve the problems of easy grinding deviation, difficulty in guaranteeing parallelism and flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

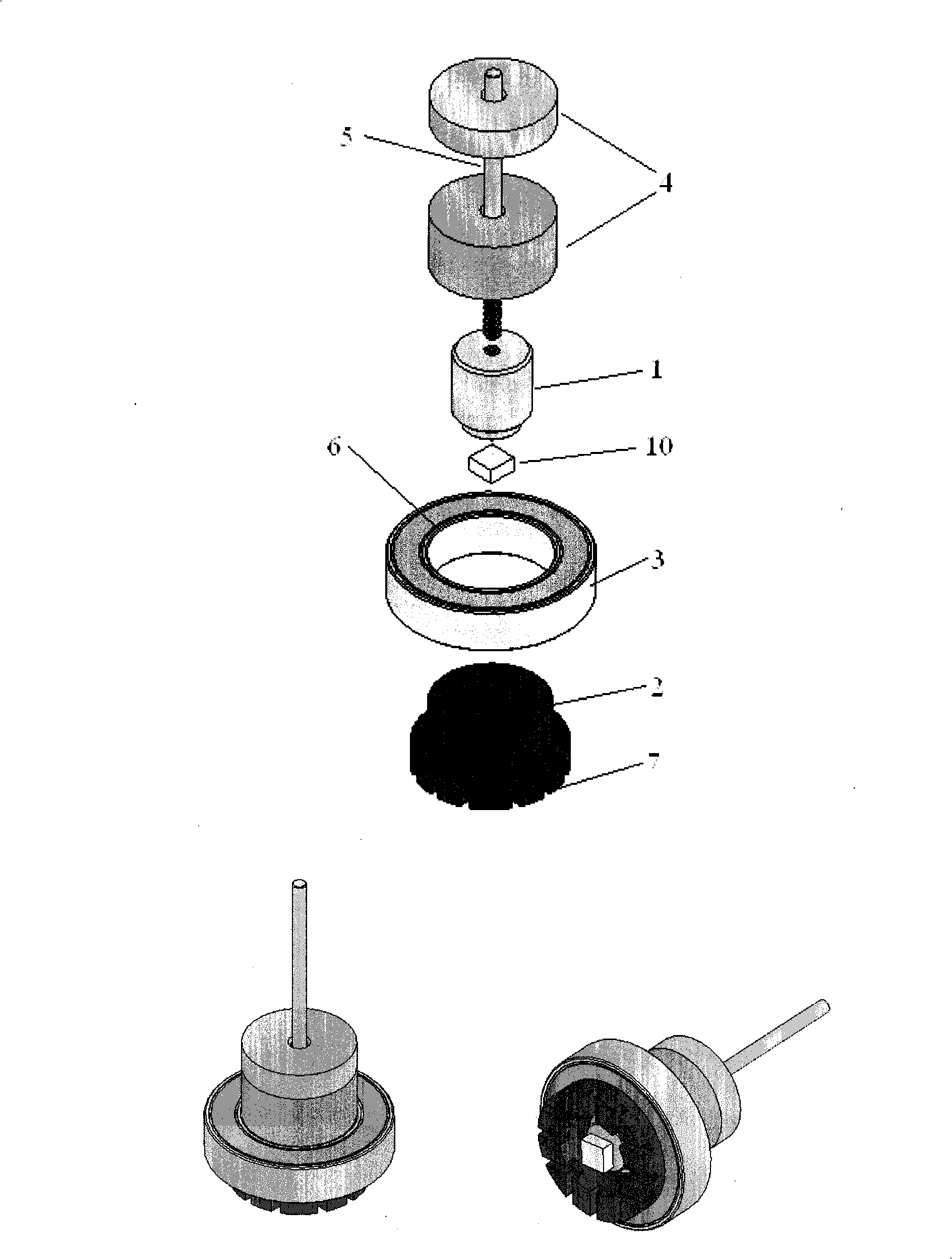

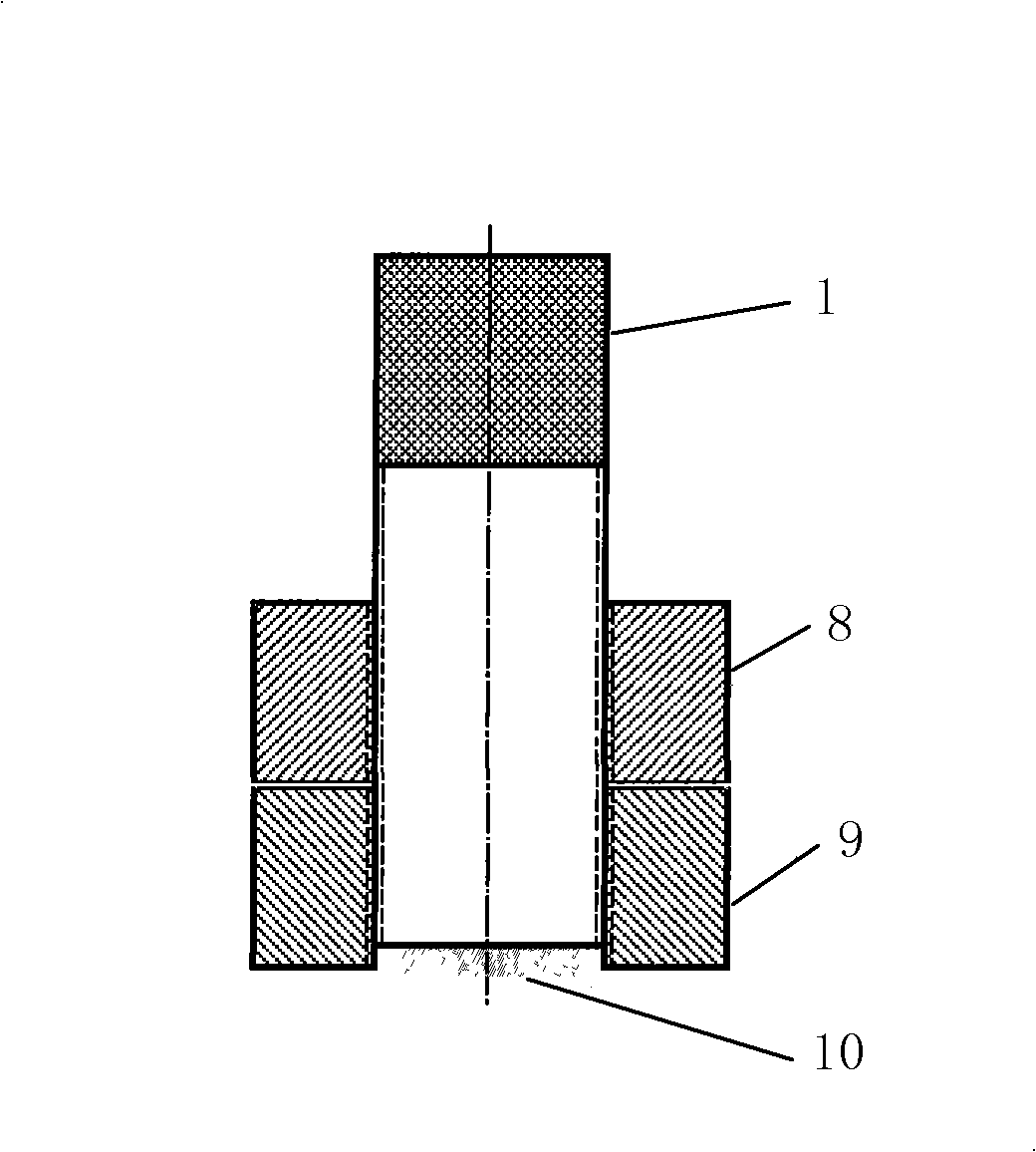

[0028] In order to ensure wear resistance and corrosion resistance, the fixed ring is made of martensitic stainless steel 4Cr13. Figure 4 Machining, then vacuum quenching at 1020°C, then tempering at 350°C.

[0029] The stage, counterweight and counterweight support rod have no wear resistance requirements, and 304 austenitic stainless steel is selected, according to Figure 5 ~ Figure 7 It can be processed.

[0030] According to the size of the fixed ring, ordinary 6008-2RS deep groove ball bearings are selected. The bearings have sealing sleeves on both sides to prevent abrasives and liquids from entering the bearings to cause wear and corrosion. If the rust resistance of the bearing is considered, stainless steel bearings can be used, but the cost will increase slightly.

[0031] After the above parts are ready, press figure 2 The assembly shown is the handheld grinding disc of the present invention. The cost of producing a single piece of the grinding disc (including...

example 1

[0033] Utilize the grinding disc of the present invention to carry out the mechanical grinding of the electron microscope sample, after the mechanical grinding to 30 μm, carry out pit grinding and ion thinning again, the electron microscope photo of the sample is as follows Figure 8 As shown, the thin areas on the obtained samples are large and uniform.

example 2

[0035] Utilize grinding disc of the present invention to prepare metallographic sample, its metallographic structure photo is as Figure 9 As shown, the surface flatness of the obtained samples is relatively high.

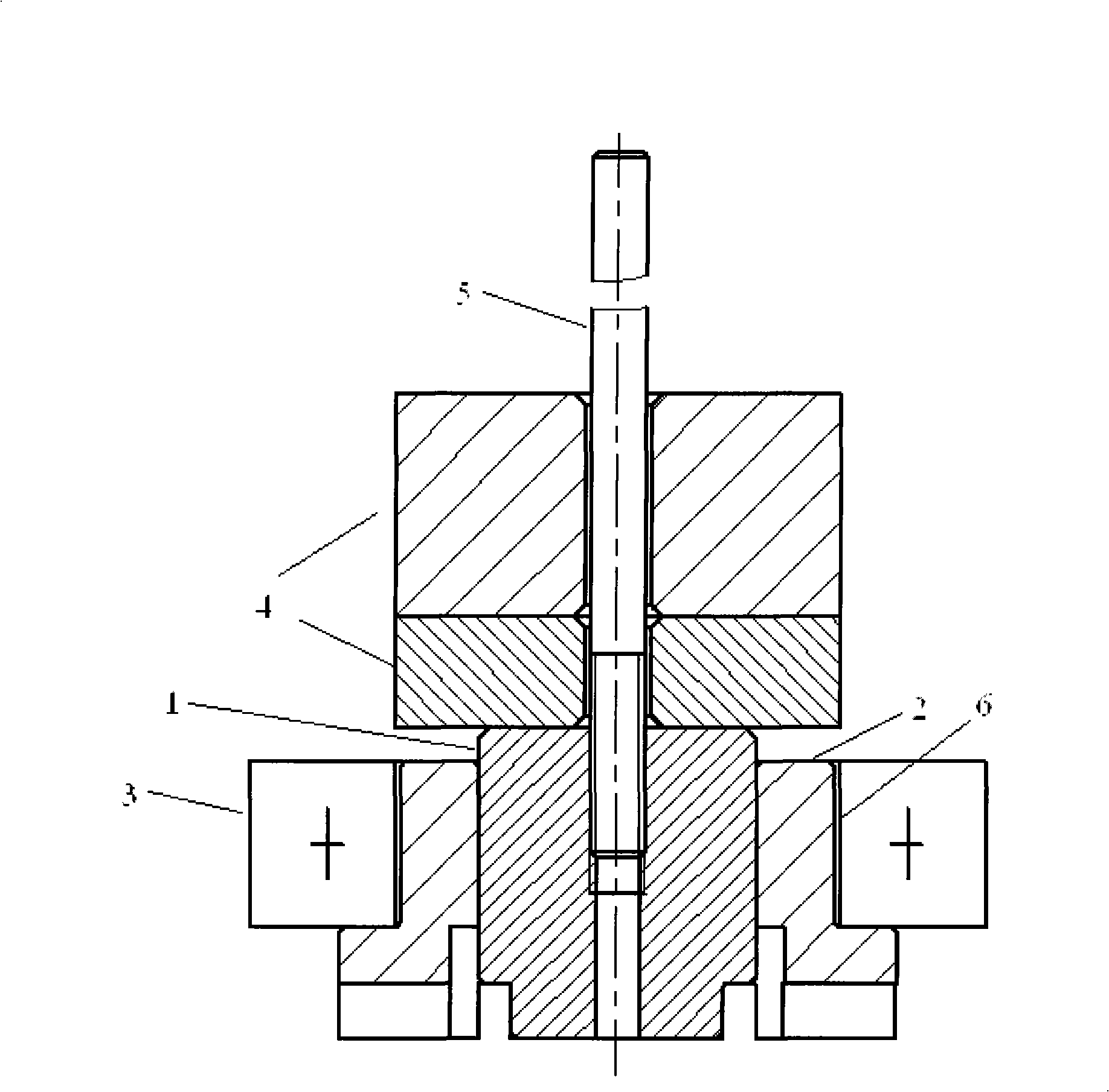

[0036] It should be noted that the grinding disc of the present invention should be figure 1 Assembled in the sequence shown, when grinding on a grinder-polisher, the sample is rotated during grinding. If you do not want the sample to rotate, or manually grind on the sandpaper, you can not assemble the bearing (see the assembly diagram Figure 10 ). It can also be pressurized manually. At this time, the counterweight and support rod need to be removed, and the upper part of the stage can be pressed with fingers when grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com