High-pressure penetration deformation testing method of reservoir grit stone dam materials

A technology of sand-gravel dam and test method, applied in the field of test, can solve the problems of limited test pressure, large pressure fluctuation, unstable water pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

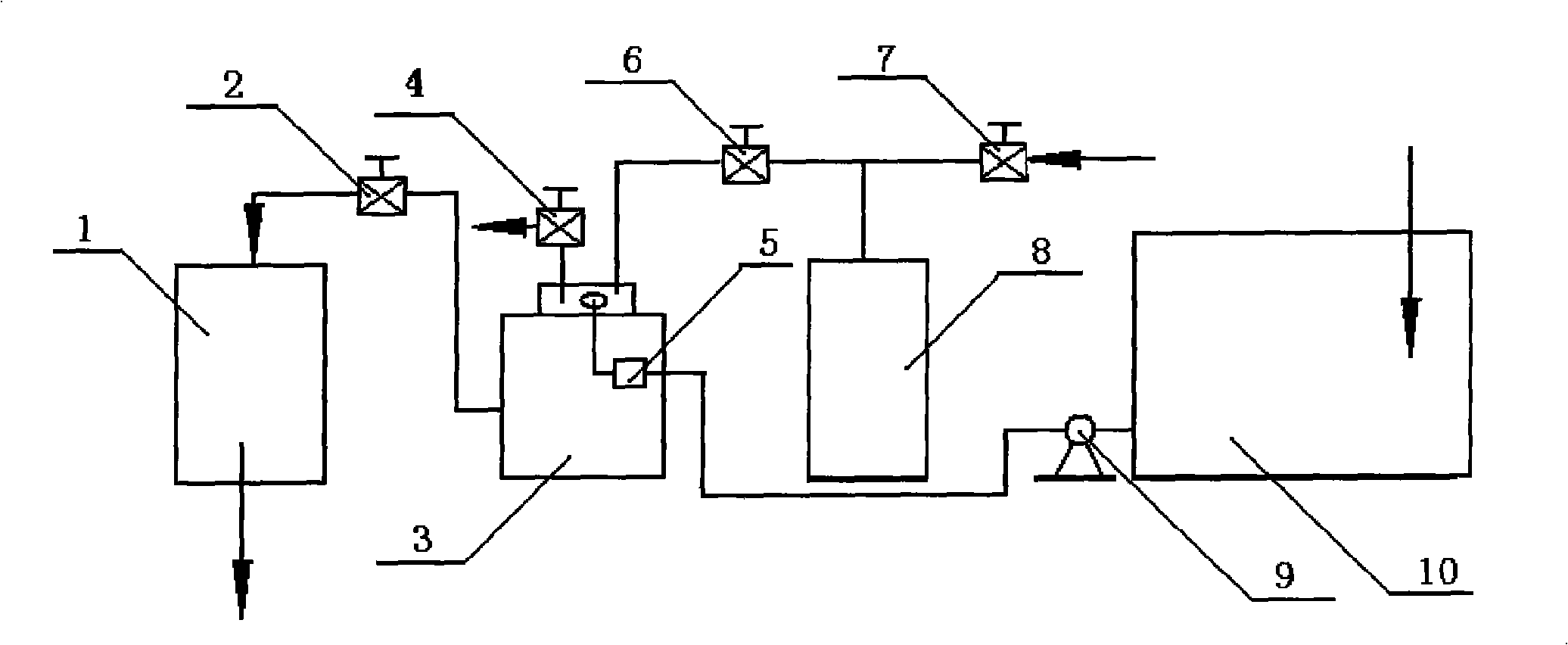

Method used

Image

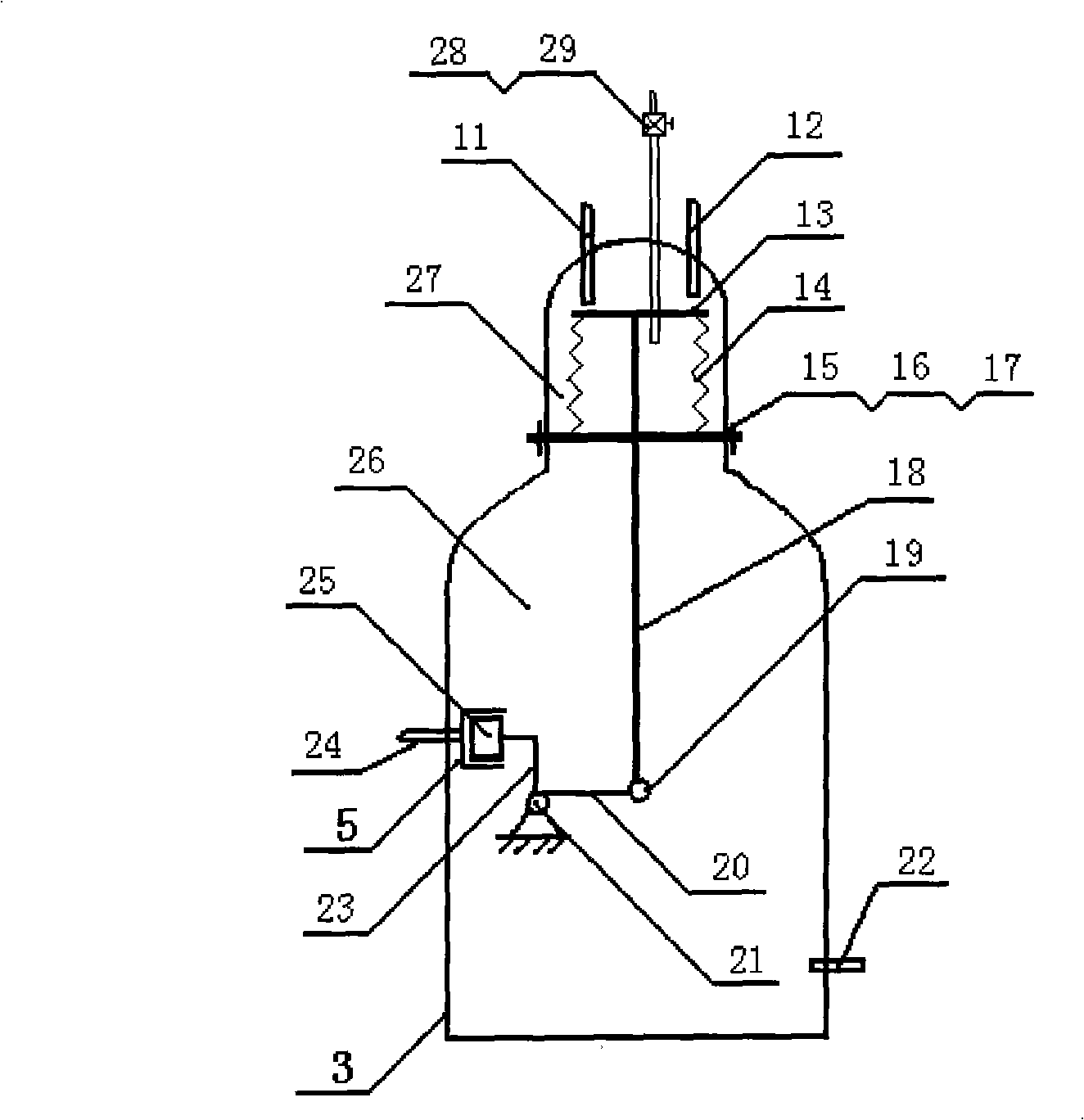

Examples

Embodiment 1

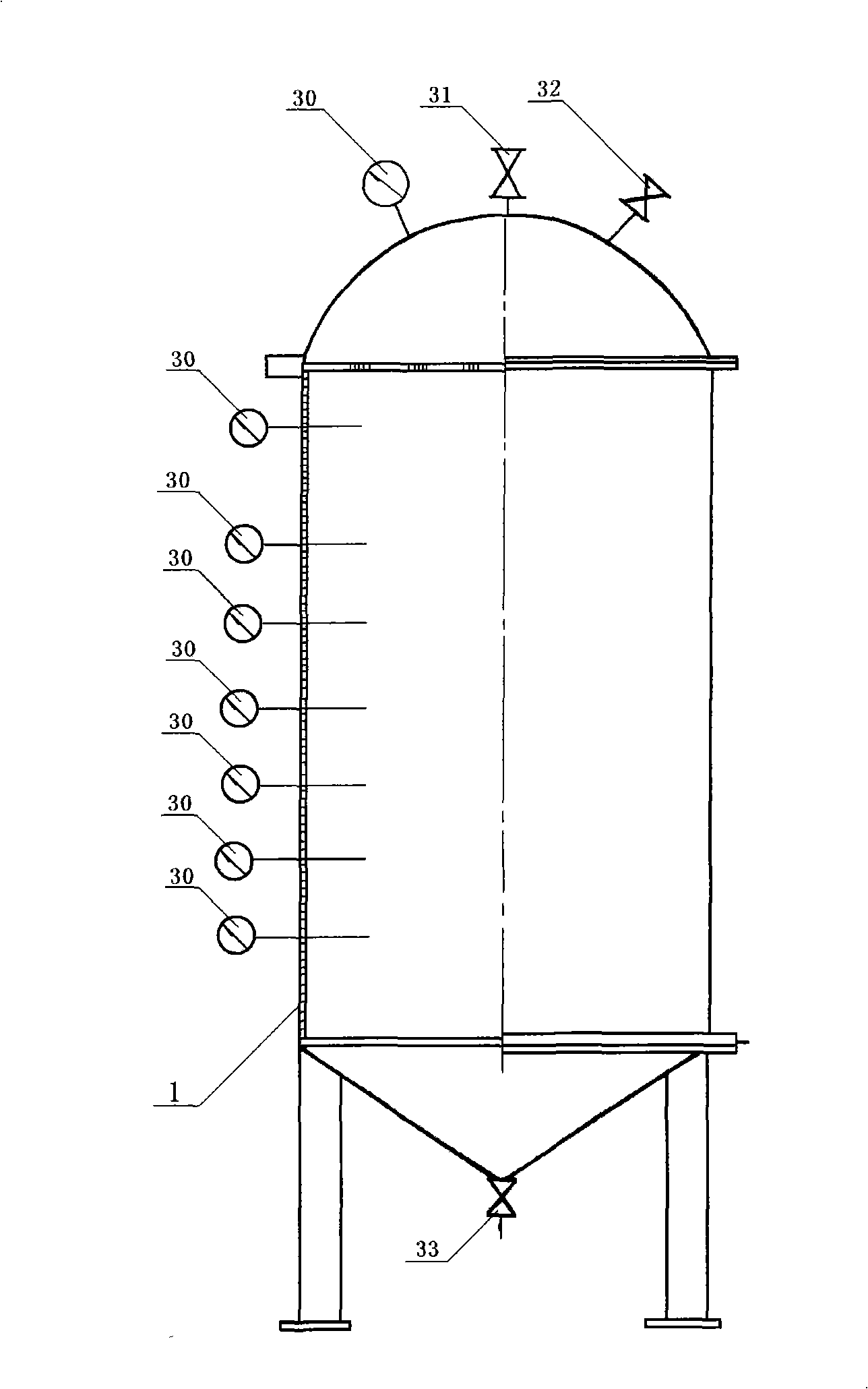

[0024] 1. The large-scale high-pressure permeameter 1 of the present invention is selected by welding high-quality steel plates with a thickness of 10-12 mm. The large-scale high-pressure permeameter 1 of the present invention is to meet the interlayer transition test of cushion material, filter material, main stack material, etc., and permeameter test The height of the cylinder is 1200mm, the total height of the permeameter is 2400mm, and the diameter of the permeameter test cylinder is 800mm; in order to meet the 100-meter head pressure test, the maximum working pressure of the permeameter is 1.0Mpa; the maximum particle size of the sample, the test dam material, is 200mm; Set the permeameter pressure gauge 30, the permeameter exhaust valve 31, the permeameter water inlet valve 32, the permeameter drain valve 33 and 8 pressure gauges 30, such as image 3 Shown

[0025] 2. Since the maximum water head of the test is 100m, the tap water cannot be directly pressurized to meet the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com